Dijual Mesin Pengupas Bawang Putih Gondor

Mesin pengupas bawang putih industri adalah peralatan dapur efisien yang digunakan untuk menghilangkan kulit luar bawang putih dengan cepat. Prinsip kerjanya adalah menggunakan pneumatik untuk mengolah bawang putih yang dipecah menjadi siung bawang putih tanpa ada kerusakan. Lebih-lebih lagi, peralatannya mudah dioperasikan. Masukkan saja bawang putih ke dalam mesin, nyalakan sakelar, dan Anda bisa mengupas siung bawang putih dalam beberapa detik. Di samping itu, perancangan mesin pengupas bawang putih memperhitungkan pengurangan kerugian, melindungi integritas siung bawang putih, dan meningkatkan efisiensi pemrosesan.

Spesifikasi Mesin Pengupas Bawang Putih

| Model | Ukuran(mm) | Berat(kg) | Voltase(ay) | Kekuatan(kw) | Menghasilkan(kg/jam) |

| GD-30 | 500*460*780 | 40 | 220 | 0.2 | 30 |

| GD-150 | 620*600*1300 | 80 | 220 | 0.2 | 150 |

| GD-300 | 700*720*1380 | 95 | 220 | 0.2 | 300 |

| GD-500 | 1000*720*148 | 140 | 220 | 0.2 | 500 |

Pasar Aplikasi Pengupas Bawang Putih Industri Gondor

- Dapat mengupas bawang putih secara efisien, memberikan kemudahan dalam pengolahan siung bawang putih, dan meningkatkan efisiensi produksi dan kualitas produk.Pabrik Pengolahan Bawang Putih

- Peralatan tersebut dapat dengan cepat mengupas bawang putih dalam jumlah besar untuk memenuhi kebutuhan produksi pabrik bumbu dalam produksi bubuk bawang putih, butiran bawang putih dan bumbu lainnya.Pabrik Bumbu

- Butiran bawang putih sering digunakan dalam bumbu mie instan. Mesin pengupas bawang putih dapat menyediakan bawang putih kupas untuk pabrik mie instan untuk menjamin kualitas dan rasa bumbu.Pabrik Mie Instan

- Mesin pengupas bawang putih rumah tangga kecil mudah dioperasikan, nyaman dan cepat, dan dapat memenuhi kebutuhan sehari-hari keluarga.Penggunaan di Rumah

- Saat membuat masakan bawang putih, roti bawang putih dan hidangan lainnya, dibutuhkan bawang putih kupas dalam jumlah besar. Peralatan ini dapat mengurangi intensitas tenaga kerja staf dapur dan meningkatkan efisiensi kerja.Hotel dan Restoran

- Kantin besar seperti kantin sekolah dan kantin perusahaan perlu mengonsumsi bawang putih dalam jumlah besar setiap hari. Mesin tersebut dapat dengan cepat mengolah bawang putih untuk memenuhi kebutuhan katering kantin.Kantin

- Operator perorangan di pasar grosir sayuran besar perlu mengupas bawang putih sebelum menjualnya. Mesin pengupas bawang putih dapat meningkatkan efisiensi kerja dan meningkatkan nilai tambah produk.Pasar Grosir Hasil Pertanian

Keunggulan Kualitas Luar Biasa Mesin Pengupas Bawang Putih Gondor

Dengan sistem tenaga yang kuat, ini dapat dengan cepat menyelesaikan pengupasan bawang putih dalam jumlah besar dalam waktu singkat, sangat meningkatkan efisiensi produksi dan menghemat waktu dan biaya tenaga kerja.

Desain canggih dan mode kerja yang tepat memastikan tingkat pengupasan bawang putih mendekati 100%, mengurangi kebutuhan pemrosesan sekunder dan memastikan kualitas dan efek pemrosesan.

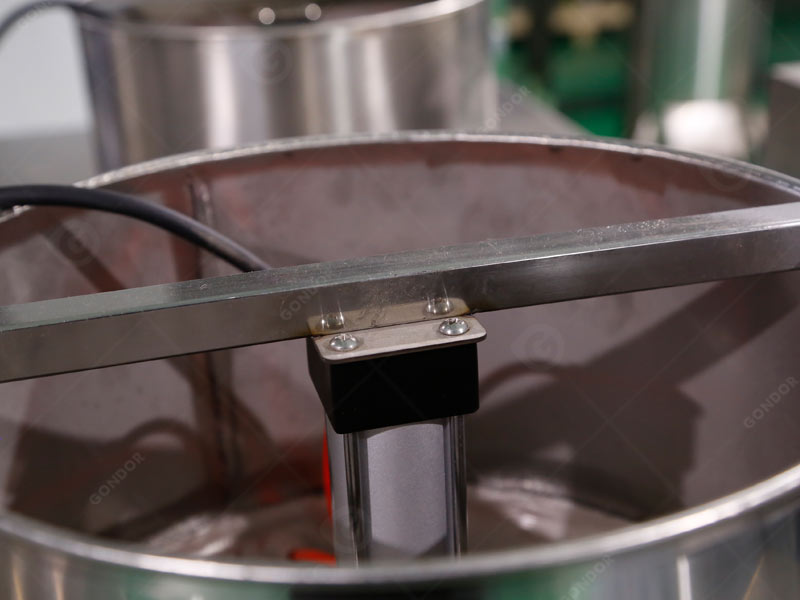

Menggunakan prinsip pneumatik untuk mengupas, itu tidak akan menyebabkan kerusakan pada bawang putih, menjaga keutuhan dan kualitas bawang putih, dan lebih kondusif untuk penyimpanan dan pemrosesan serta penggunaan selanjutnya.

Dengan antarmuka dan desain operasi yang manusiawi, proses pengoperasiannya sederhana dan mudah dimengerti, tanpa memerlukan pelatihan yang rumit dan keterampilan profesional.

Desain strukturalnya masuk akal, dan setiap komponen mudah dibongkar dan dipasang, yang memudahkan pengguna untuk membersihkan mesin secara menyeluruh setelah digunakan.

Desain penutup pelepasan sangat perhatian dan praktis, yang dapat dengan mudah mengumpulkan bawang putih yang sudah dikupas agar tidak berserakan, membuat operasi lebih nyaman dan efisien, dan meningkatkan efisiensi kerja.

Mesin Pengupas Bawang Putih Industri Gondor – Penolong yang Baik di Dapur

Apakah Anda ingin menghilangkan kerumitan mengupas bawang putih dengan mudah? Mesin pengupas bawang putih ini adalah pilihan ideal anda. Mudah dioperasikan, masukkan saja bawang putihnya, dan bisa dikupas dengan cepat. Dan ukurannya kecil dan tidak memakan tempat. Klik di bawah untuk mengirimkan pertanyaan. Datang dan miliki mesin pengupas bawang putih ini dan mulailah perjalanan memasak yang nyaman.

Proses Pengupasan Bawang Putih Industri

Mesin pengupas bawang putih industri adalah peralatan khusus yang memanfaatkan teknologi pemisahan udara yang kuat, teknologi pemecah cangkang tekanan udara, atau teknologi gesekan putar untuk menghilangkan lapisan luar bawang putih dengan cepat. Sepanjang proses, siung bawang putih jangan langsung bersentuhan dengan bilahnya, mencegah kerusakan. Ini adalah metode pengelupasan tanpa air yang bersih, higienis, dan sangat efisien.