Gondor Liquid Filling Machine

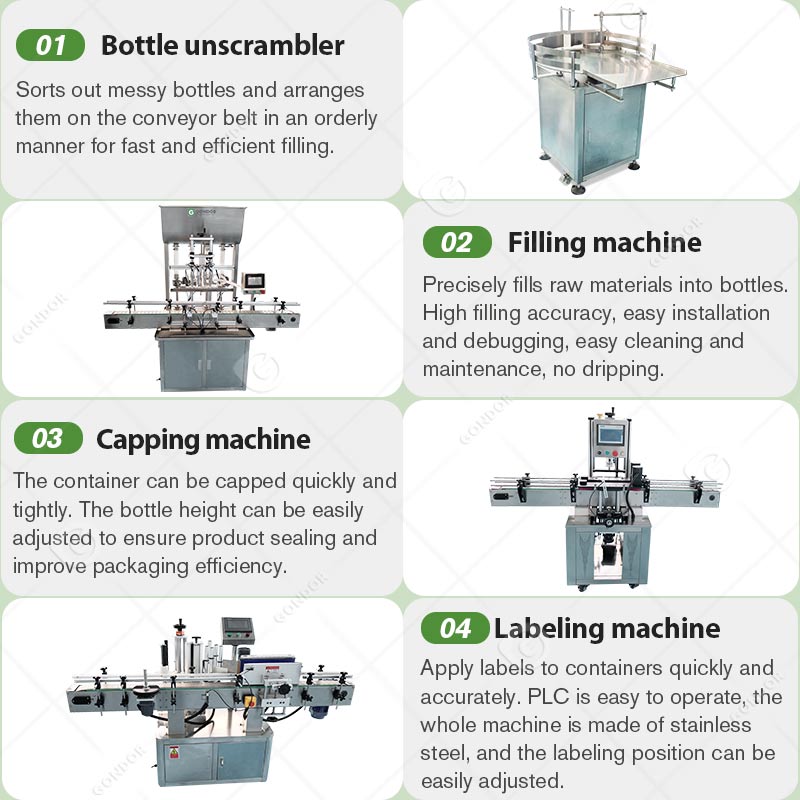

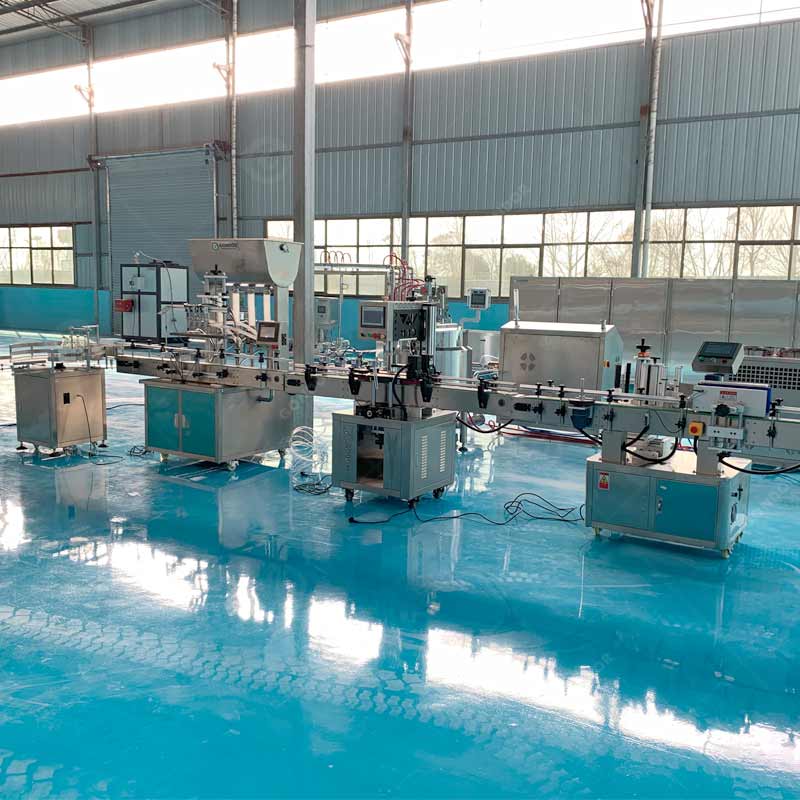

Ini jalur pengisian cairan mengintegrasikan penyortiran botol otomatis, pengisian yang tepat, penyegelan berkecepatan tinggi, dan pelabelan cerdas, membentuk sistem pengemasan otomatis yang komprehensif. Seluruh lini mengadopsi sistem kontrol cerdas PLC, dikombinasikan dengan modul pengisian presisi tinggi, yang dapat mengontrol kesalahan pengisian setiap botol cairan di dalamnya 1%, sehingga memenuhi kebutuhan kecepatan tinggi, skala besar, dan produksi presisi. Pada saat yang sama, peralatannya terbuat dari food grade 304 baja tahan karat, yang sesuai dengan standar kesehatan internasional, dan tidak hanya stabil dalam pengoperasian tetapi juga nyaman dalam pemeliharaan, sehingga sangat cocok untuk industri pengemasan cairan modern.

Liquid Filling Production Line Specification

| Produk | Pengurai botol | Mesin Pengisian | Mesin Pembatas | Mesin Pelabelan |

| Voltase | 220ay | |||

| Kekuatan | 120w | 500w | 0.8kw | 1.5kw |

| Menghasilkan | / | 5-60 botol/menit | 30-60 potongan/menit | 20-200 potongan/menit |

| Berat | 120kg | 800kg | 550kg | 270kg |

| Ukuran(mm) | 1250*1250*1350 | 2000*1250*1600 | 2000*850*1800 | 1220*1250*1470 |

| Diameter Botol | / | / | ∅35-∅140mm | ∅30-∅180mm |

| Tinggi Label | / | / | / | 15-150mm |

| Panjang Label | / | / | / | 25-300mm |

| Diameter Tutup Botol | / | / | 20-100mm | / |

Aplikasi Industri Lini Produksi Pengisian Cairan

Lini produksi pengisian ini sangat cocok untuk pengemasan berbagai produk cair, mencakup berbagai industri, termasuk namun tidak terbatas pada:

Kinerja Luar Biasa dari Lini Produksi Cairan

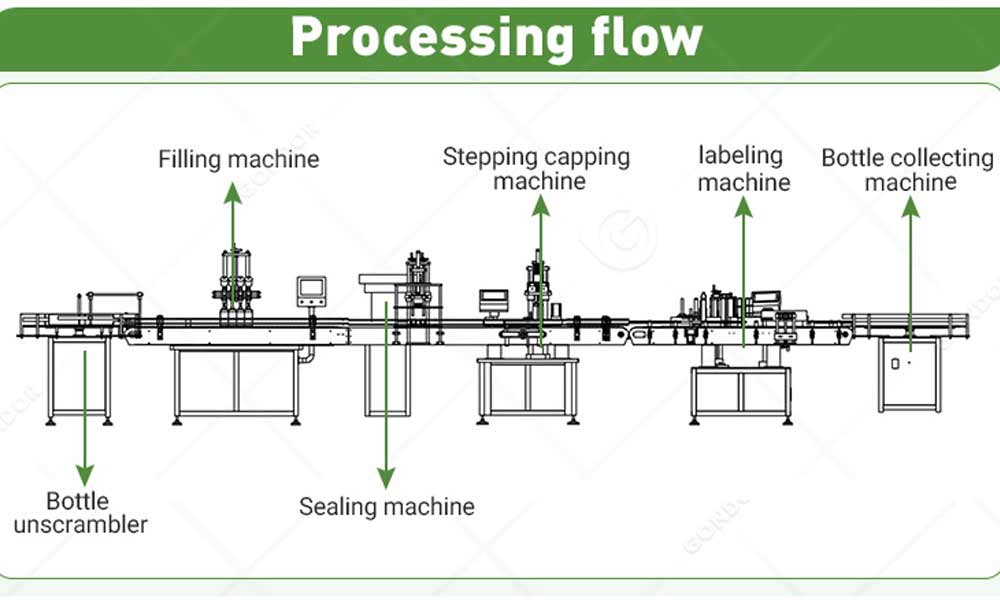

Liquid Filling Line Workflow

Liquid filling machines are based on zoned control and synchronous tracking. The production line is centrally scheduled by a PLC. Sensors at each station (photoelectric, proximity switches, dll.) detect the container position and feed the signals back to the control system, which then directs the corresponding mechanisms (such as filling heads and capping heads) to complete precise actions at the moment of movement or stillness.

A typical workflow is as follows (taking beverage bottles as an example):

Empty Bottle Supply: Empty bottles, after being depalletized or exiting from the upstream blow molding machine, are fed into the production line in a single, evenly spaced column by a conveyor belt.

Empty Bottle Cleaning (if required): Bottles are rinsed with purified air or sterile water at an inverted rinsing station with the bottle neck facing down.

Alignment and Filling: The conveyor belt delivers the bottles to the rotary table or linear filling station of the filling machine, where the bottle neck is precisely positioned below the filling valve.

Immediate Sealing: Filled bottles are immediately sent to the sealing unit, where the capping head grabs the cap and tightens it, or a capping machine presses on the crown cap.

Secondary sealing and labeling: This may involve aluminum foil sealing, heat shrink film sealing, dll.. The product then enters the labeling machine for precise affixing of the main label.

Online inspection and marking: A checkweigher removes products with insufficient filling volume; a vision inspection system checks the liquid level, penyegelan, and labeling quality; an inkjet printer prints the production date and batch number on the bottle or label.

Finished product output: Qualified products are collected by a conveyor belt and automatically packed into cartons or crates by a case packer. Akhirnya, they may be stacked into palletized stacks by a palletizing robot, awaiting warehousing.

Rekomendasi Peralatan yang Cocok

Untuk membangun yang lebih efisien, bengkel pengemasan sepenuhnya otomatis, Anda juga dapat mempertimbangkan untuk menggunakan peralatan berikut:

- Penyegel Karton

- Pencetak Inkjet

- Mesin Terowongan Penyusut Panas

- Sistem Konveyor