Pengenalan lini produksi Bakso Gondor

Otomatis mesin pembuat bakso adalah solusi modern yang dirancang untuk menyederhanakan dan meningkatkan pembuatan bakso. Mengintegrasikan cincang, pemotongan mangkuk, pembentukan, opsional menggoreng atau merebus, pendinginan, dan pembekuan cepat, ini memberikan efisiensi tinggi dan kualitas yang konsisten di setiap langkah. Dibuat dengan baja tahan karat food grade dan otomatisasi canggih, jalur produksi bakso otomatis memastikan keluaran yang stabil, tekstur unggul, dan pengolahan higienis yang aman, menjadikannya pilihan ideal untuk produksi bakso profesional.

>

Model Lini Produksi Bakso Gondor

Lini pengolahan bakso kami terdiri dari satu set peralatan lengkap, di bawah ini adalah beberapa model peralatan.

| Produk |

Mesin Penggiling Daging Beku |

Mesin Pemotong Mangkuk |

Mesin Pembentuk Bakso |

Mesin Penggorengan Berkelanjutan |

Mesin Blanching |

Pendinginan & Mesin Pengering |

Mesin freezer terowongan |

| Voltase |

380ay |

220ay |

380ay |

| Kekuatan |

5.5kw |

4.1kw |

1.1kw |

48kw |

40kw |

3.5kw |

20kw |

| Keluaran |

500kg/jam |

15k/bisa |

280buah/menit |

/ |

/ |

/ |

100kg/jam |

Penerapan Mesin Pembuat Bakso Gondor

Usaha yang Menggunakan Jalur Produksi Pengolahan Bakso Gondor

Mesin pembuat bakso otomatis Gondor melayani dapur pusat, pabrik pengolahan makanan, pemasok makanan beku, restoran berantai, dan perusahaan katering, di samping supermarket skala besar dan pusat distribusi.

Dapur PusatPabrik Pengolahan MakananPemasok Makanan BekuPerusahaan Jaringan RestoranSupermarket BesarPusat Distribusi

Menyesuaikan dengan sebagian besar kebutuhan pra-produksi di dapur pusat, dengan proses yang sepenuhnya otomatis untuk produksi bakso terstandarisasi yang efisien, memfasilitasi pengiriman makanan yang cepat dan kualitas yang konsisten.

Memenuhi kebutuhan produksi skala besar pada pabrik pengolahan pangan, dengan kontrol otomatis penuh di seluruh proses, memastikan konsistensi rasa dan spesifikasi bakso, meningkatkan kapasitas produksi dan hasil.

Menyesuaikan dengan persyaratan pemrosesan makanan beku, dengan jalur produksi yang terhubung ke peralatan makanan beku di bagian akhir untuk penguncian kesegaran yang cepat, memastikan kualitas bakso yang stabil setelah dibekukan.

Memberikan solusi bakso standar untuk jaringan restoran, menyatukan rasa dan bentuk produk, mengurangi kesulitan operasional dan biaya di dapur toko.

Lini tersebut dapat menyesuaikan kapasitas produksi dan spesifikasi pengemasan sesuai kebutuhan, sehingga memproduksi secara massal bakso yang cocok untuk supermarket dan selanjutnya memastikan pasokan yang stabil dan kesegaran rak.

Bakso terstandar yang diproduksi oleh lini produksi mudah disimpan dan diangkut, beradaptasi dengan pergudangan terpusat dan kebutuhan distribusi lintas wilayah pusat distribusi, mengurangi kerugian.

Bahan Baku Yang Cocok Untuk Mesin Pembuat Bakso Gondor

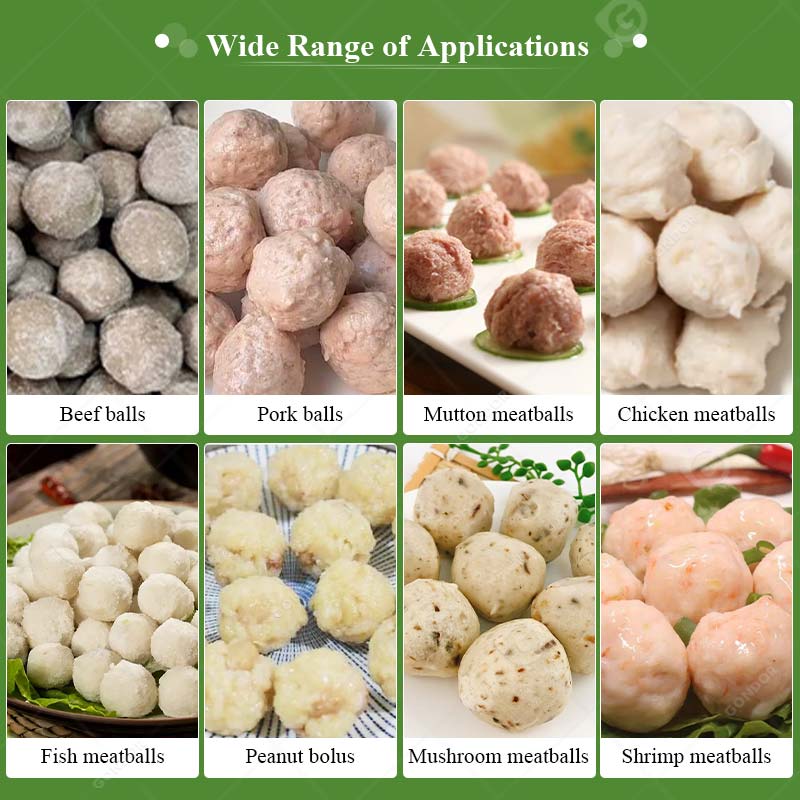

Lini tersebut dapat memproduksi berbagai jenis bakso, termasuk bakso sapi, bola babi, bola ikan, bola ayam, dan bakso isi. Dengan penggorengan atau blansing opsional, ini mendukung gaya pemrosesan yang berbeda untuk memenuhi beragam kebutuhan pasar seperti bahan hot pot, makanan cepat saji, makanan siap santap, dan produk ritel beku.

>

Fitur Alat Pengolahan Bakso Gondor

Produksi Sepenuhnya Otomatis Dan Sangat Efisien

Mulai dari pengolahan bahan mentah hingga hasil produk jadi, seluruh proses otomatis, secara signifikan mengurangi intervensi manual dan secara signifikan meningkatkan efisiensi produksi dan output bakso per satuan waktu.

Stabil, Seragam, Dan Kualitas Terkendali

Proses terstandar dan kontrol parameter yang tepat memastikan rasa yang konsisten, ukuran, dan kekenyalan pada setiap batch baksonya, meningkatkan penerimaan pasar.

Konfigurasi Fleksibel Dapat Beradaptasi Dengan Beragam Proses

Mendukung mesin penggorengan atau blansing berkelanjutan opsional, memungkinkan peralihan yang fleksibel antara menggoreng dan merebus sebagai dua proses inti untuk memenuhi kebutuhan produksi bakso dengan rasa berbeda.

Mengurangi Biaya Keseluruhan Secara Signifikan

Otomatisasi mengurangi input tenaga kerja, mengoptimalkan konsumsi energi dan pemanfaatan material, dan menurunkan tingkat kecacatan, mengompresi keseluruhan biaya produksi bakso dari berbagai dimensi.

Lini Produksi Bakso Gondor Termasuk Peralatannya

Mesin Penggiling Daging Beku

Penggiling daging beku mengolah daging beku secara langsung—mencegah pertumbuhan mikroba, menjaga kesegaran/keamanan, dan menghasilkan butiran yang seragam untuk pencacahan yang optimal.

Mesin Pemotong Mangkuk

Inti garis: mencampur daging giling dengan bahan tambahan/es/pati; bilah berkecepatan tinggi mengemulsi untuk mengekstrak protein yang larut dalam garam agar empuk, pasta elastis.

Mesin Pembentuk Bakso

Itu

mesin pembentuk bakso secara otomatis menghasilkan bakso dengan ukuran dan berat yang seragam—ukuran porsinya dapat disesuaikan, efisiensinya stabil, dan ketidakkonsistenan operasi manual dihilangkan.

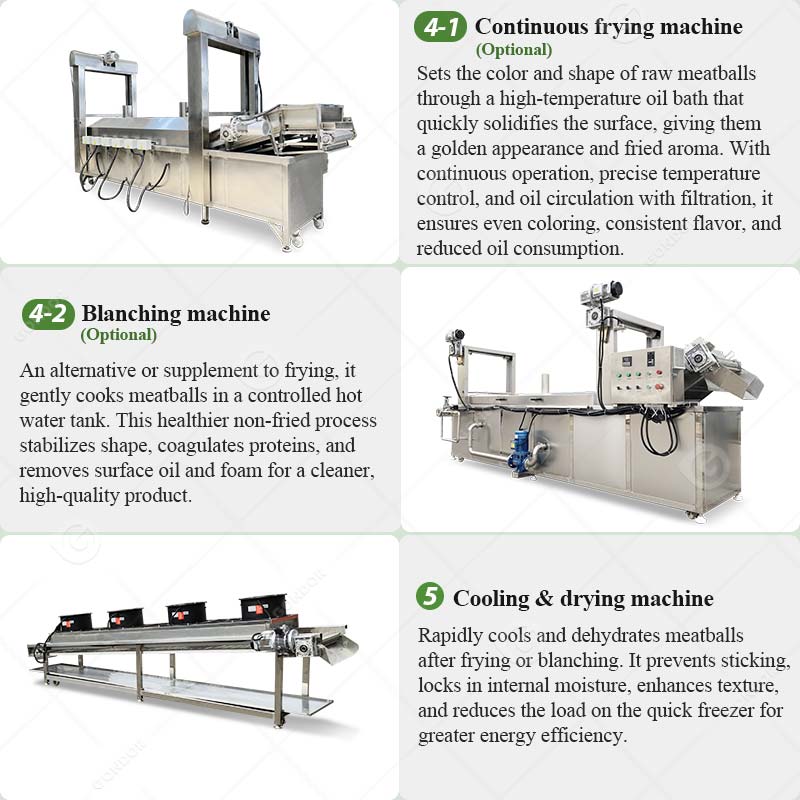

Mesin Penggorengan Berkelanjutan Opsional

Pemandian minyak bersuhu tinggi membentuk warna emas, bakso aromatik—kontrol suhu yang tepat, penyaringan minyak, konsumsi energi yang rendah.

Mesin Blanching Opsional

Alternatif tanpa digoreng: juru masak air panas yang terkontrol—menstabilkan bentuk, mengkoagulasi protein, menghilangkan minyak/busa untuk kualitas tinggi.

Pendinginan & Mesin Pengering

Dinginkan/keringkan setelah digoreng/blansing—mencegah lengket, mengunci kelembapan, meningkatkan tekstur, mengurangi beban freezer.

Mesin Pembeku Terowongan

-35℃ aliran udara dingin membeku dengan cepat (inti ≤-18℃)—

Freezer terowongan menjaga makanan tetap segar dan juicy, menghambat pertumbuhan bakteri, dan memperpanjang umur simpan.

Mengapa Memilih Peralatan Kami?

- Rangkaian Produk Komprehensif: Menghasilkan bakso daging sapi, bola babi, bola ikan, dan banyak lagi, melayani preferensi konsumen yang beragam.

- Proses Penggorengan Untuk Berbagai Skenario: Teknologi penggorengan opsional menghasilkan bakso yang renyah, secara sempurna memenuhi permintaan pasar akan makanan cepat saji dan makanan siap saji.

- Solusi Blanching Khusus: Memanfaatkan proses blansing untuk menjaga kesegaran bahan asli, sangat cocok untuk bahan hot pot dan produksi makanan sehat.

- Dukungan Kustomisasi Ritel Beku: Kompatibel dengan prosedur pemrosesan beku, menghasilkan bakso yang tahan lama dan mudah diangkut, memenuhi kebutuhan pasokan saluran ritel beku.

- Dukungan Kustomisasi Logo dan Model: Dengan berakhir 20 pengalaman bertahun-tahun di bidang manufaktur mesin makanan, kami dapat menyesuaikan mesin dengan model yang Anda inginkan dan menambahkan logo Anda.