Gondor Pet Food Production Line

Itu jalur pengolahan makanan hewan disediakan oleh Gondor mengintegrasikan otomatisasi, kapasitas produksi tinggi dan kontrol suhu yang tepat, dan cocok untuk produksi makanan hewan untuk anjing, kucing, ikan, burung, dll.. Produk berkualitas tinggi dipastikan melalui proses seperti penyesuaian formula, cetakan perubahan cetakan, dan pemeriksaan kualitas yang ketat. Proses produksi secara ketat mengontrol rasio bahan baku dan menggabungkan teknologi puffing untuk menghasilkan makanan hewan yang renyah dan bergizi seimbang, yang sangat populer di pasar global.

Pet Food Processing Line Specification

| Nama | Kekuatan(kw) | Voltase(ay) | Berat(kg) | Ukuran(mm) | Kapasitas(kg/jam) |

| Pengaduk | 7.5 | 380v/50hz | 222 | 850x530x1040 | 40-50kg/waktu |

| Pengumpan spiral | 1.5 | 100 | 850x750x2450 | Dengan tuan rumah | |

| Pembangkit uap | 72 | 200 | 900x800x1200 | 100 | |

| Ekstruder sekrup kembar | 35 | 1473 | 2500x1000x1800 | 220-300kg/jam | |

| Konveyor udara | 0.75 | 41 | 2000x600x1900 | Dengan tuan rumah | |

| Pengering | 40 | 2000 | 5300x1200x1900 | Dengan tuan rumah | |

| Mesin bumbu | 3.5 | 234 | 3100x900x1800 | Dengan tuan rumah |

Lini Pengolahan Makanan Hewan Cocok untuk Berbagai Industri

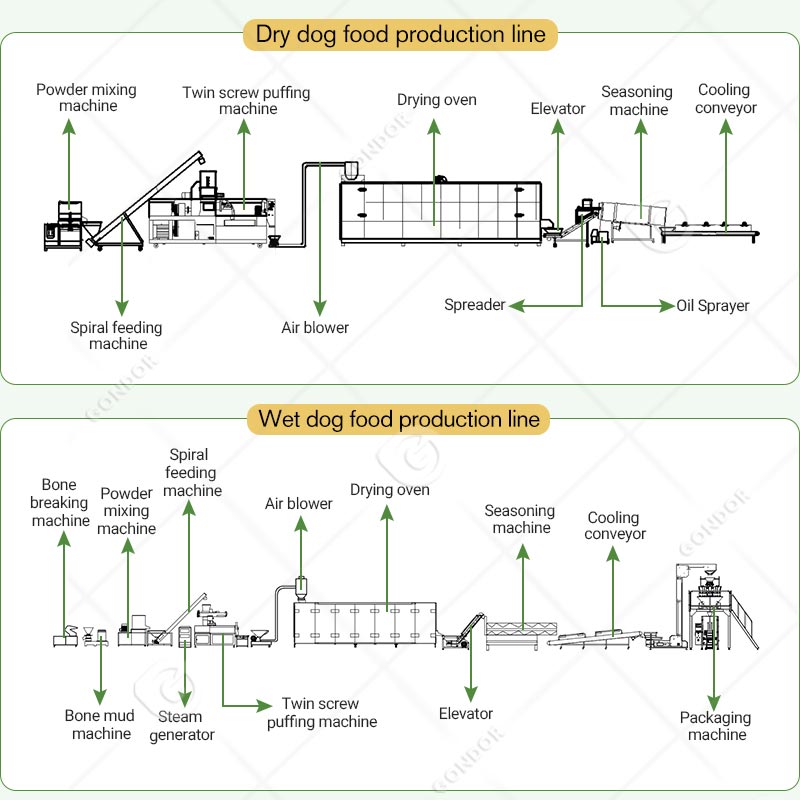

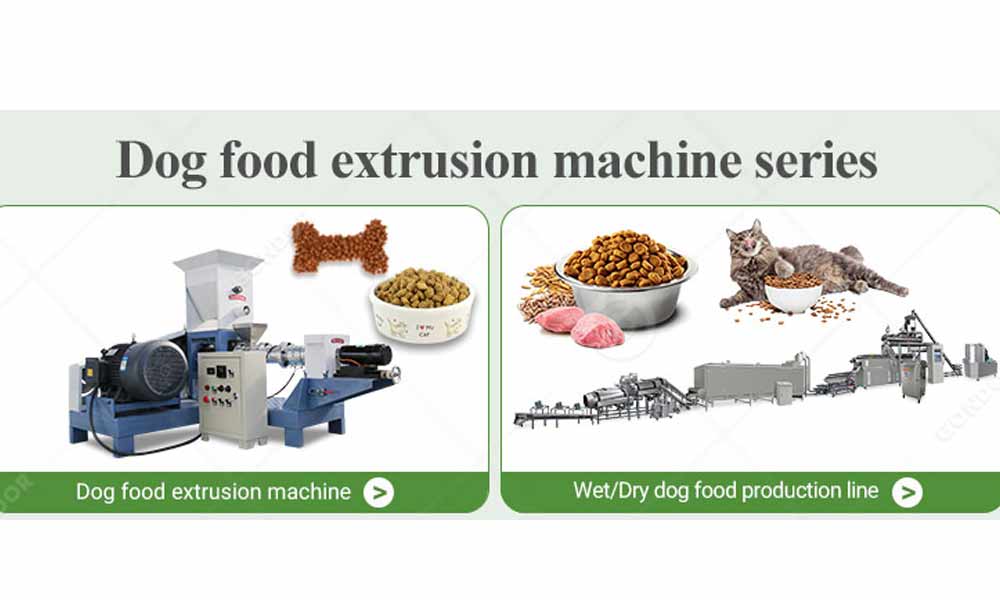

Jalur pengolahan makanan hewan ini banyak digunakan di banyak industri seperti produsen makanan hewan, pabrik pengolahan pakan ternak, merek makanan hewan, perusahaan perdagangan, Perusahaan pengecoran OEM/ODM, dll., untuk memenuhi berbagai kebutuhan pasar global akan makanan hewan kering dan makanan hewan basah. Baik itu pabrik makanan hewan dengan produksi skala besar atau merek yang mencari produk khusus berkualitas tinggi, lini produksi ini dapat memberikan solusi yang efisien dan stabil. Pada saat yang sama, peralatan tersebut mendukung berbagai penyesuaian formula untuk memenuhi kebutuhan nutrisi hewan peliharaan yang berbeda, membantu perusahaan meningkatkan daya saing pasar mereka.

Keunggulan Inti dari Lini Makanan Hewan Gondor

Rekomendasi Peralatan Terkait

Untuk lebih mengoptimalkan produksi makanan hewan, kami juga menyediakan peralatan berikut untuk meningkatkan efisiensi produksi dan kualitas produk:

- Mesin Penghancur Tulang: Menghancurkan tulang menjadi partikel halus untuk penggilingan selanjutnya.

- Mesin Lumpur Tulang: Menggiling dan meremukkan tulang hingga membentuk lumpur tulang halus untuk meningkatkan penyerapan kalsium.

- Konveyor Sekrup Miring: Mengangkat material secara merata tanpa kebocoran atau polusi.

Lini pemrosesan makanan hewan kami telah diekspor ke banyak negara di dunia, membantu perusahaan makanan hewan memperluas pasar mereka dan meningkatkan daya saing mereka. Jika Anda mencari peralatan produksi makanan hewan yang efisien dan andal, silakan hubungi kami segera dan kami akan memberi Anda solusi khusus!