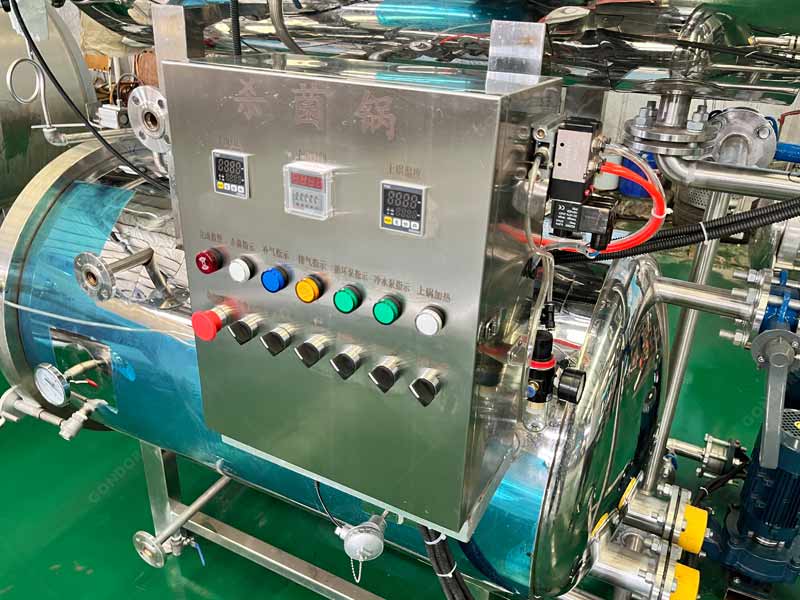

Dalam industri makanan dan farmasi, keamanan produk dan umur simpan merupakan hal yang sangat penting. Dengan kinerja sterilisasi suhu tinggi dan tekanan tinggi yang kuat, itu mesin retort telah menjadi pilihan ideal bagi perusahaan produksi makanan, perusahaan farmasi, dan laboratorium. Peralatan ini mengadopsi kontrol cerdas dan efisiensi tinggi serta desain hemat energi untuk memastikan proses sterilisasi seragam dan menyeluruh serta memaksimalkan kualitas produk.

|

Model |

SL-1000 | SL-1200 | SL-1300 | |

| Panjang silinder(mm) | 2200 | 2700 | 4000 |

4000 |

|

Panjang keseluruhan(mm) |

4000 | 4500 | 5400 | 5800 |

| Lebar keseluruhan(mm) | 1550 | 1750 | 1750 |

1850 |

|

Tinggi keseluruhan(mm) |

2850 | 3100 | 3100 | 3300 |

| Kapasitas(kg) | 500 | 800 | 1100 |

1500 |

|

Ketebalan badan pot(mm) |

4 | 5 | 5 | 4 |

| Daya terpasang(kw) | 10 | 15.5 | 18.5 |

18.5 |

|

Konsumsi gas(kg/kumpulan) |

460 | 570 | 610 | 730 |

| Konsumsi daya(kw/jam) | 7 | 14 | 14 |

16 |

|

Pers Desain(Ayah) |

0.35 | 0.35 | 0.35 | 0.35 |

|

Suhu Desain(°C) |

147 | 147 | 147 |

147 |

Area Aplikasi Alat Sterilisasi Retort

Alat sterilisasi retort banyak digunakan untuk sterilisasi berbagai bahan kemasan tahan suhu tinggi, dan cocok untuk industri dan produk berikut:

- Produk Daging: Daging makan siang, ham, ceker ayam, dendeng, dll..

- Produk Kacang: Tahu kering, produk vegetarian, saya susu, dll..

- Produk Makanan Laut: Ikan kaleng, produk kerang, dll..

- Produk Nabati: Sayuran liar, jagung, jamur enoki kalengan, dll..

- Kaleng Logam: Kaleng pelat timah, kaleng aluminium, ikan kaleng, dll..

- Botol Kaca (tidak disarankan, tetapi solusi spesifik dapat disesuaikan)

- Kantong aluminium foil

- Kantong vakum tahan suhu tinggi

- Kantong masak bersuhu tinggi

- Santan, saya susu

- Jus, minuman olahraga

- Sterilisasi limbah medis

- Sterilisasi media kultur jamur yang dapat dimakan

- Sterilisasi kayu dan tanah

Keunggulan Inti Mesin Pengolah Retort

Hubungi Kami untuk Menjelajahi Lebih Banyak Peralatan Pengolahan Makanan

Selain mesin retort, kami juga menyediakan peralatan canggih seperti penyegel vakum ruang ganda, mesin pengisian cairan, mesin pembersih buah dan sayuran, dll.. untuk membantu Anda meningkatkan lini produksi Anda! Hubungi kami untuk detail produk lebih lanjut, tim kami akan memberi Anda solusi sterilisasi paling profesional!