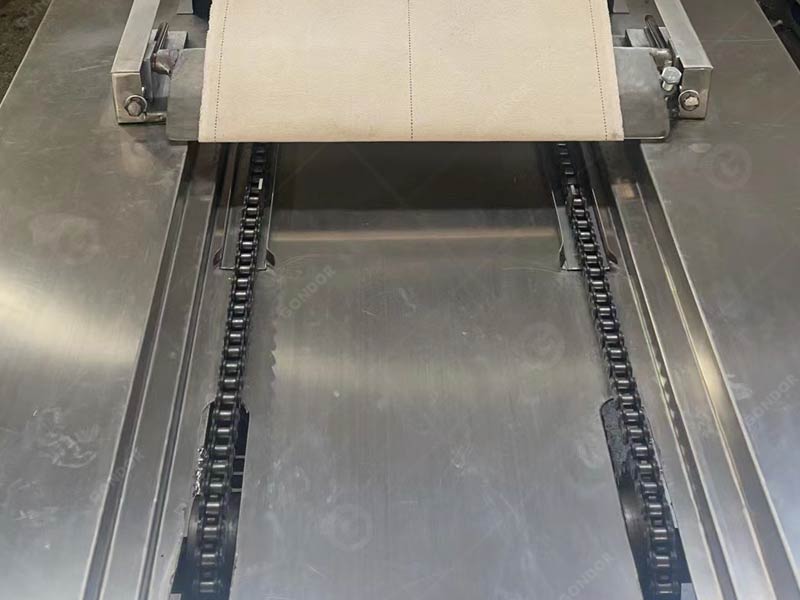

Biscuit Rotary Moulding Machine

Itu mesin pembuat biskuit cetakan putar mengintegrasikan berbagai fungsi dan secara efisien dapat menyelesaikan seluruh proses produksi mulai dari penggulungan dan pencetakan adonan hingga pembentukan dan pembongkaran biskuit. Lebih-lebih lagi, mesin ini dapat membuat biskuit dengan berbagai bentuk dan berat untuk memastikan kualitas biskuit Taosu yang stabil. Selain itu, cetakan biskuit dengan berbagai ukuran dan bentuk juga dapat disesuaikan. Ciri khas mesin pembuat biskuit adalah memiliki tingkat otomatisasi yang tinggi, yang sangat meningkatkan efisiensi produksi dan mengurangi biaya tenaga kerja.

Rotary Moulding Biscuit Molder Machine Specification

| Model | GD-400 | GD-600 | GD-800 | GD-1000 | GD-BG400 |

| Menghasilkan | 100-200 kg/jam | 250-300kg/jam | 500-600kg/jam | 800-1000kg/jam | 50-180kg/jam |

| Kekuatan | 1.5kw | 2.2Kw | 4.5kw | 5.5kw | 2.2kw |

| Voltase | 380-220v /50Hz | 380-220v /50Hz | 380-220v /50Hz | 380-220v /50Hz | 380v/50hz |

| Ukuran loyang | 400*600mm | 600*600mm | 800*600mm | 1000*600mm | 400*600mm |

| Ukuran peralatan | 2350*850*1350 | 2350*1050*1350 | 2500*1350*1350 | 2500*1550*1600 | 2900*850*1350 |

| Berat | 500kg | 850kg | 1300kg | 1500kg | 580kg |

Berbagai Pasar Aplikasi Biskuit Rotary Moulding Gondor

Pabrik Pengolahan Makanan

Produksi massal biskuit persik, memasoknya ke supermarket, toko serba ada dan saluran penjualan lainnya.

Rantai Toko Roti

Digunakan untuk membuat biskuit persik buatan sendiri di toko untuk menjamin kesegaran dan keunikan produk serta menarik pelanggan.

Platform E-niaga

Beberapa pengusaha menjual biskuit buah persik buatannya melalui platform e-commerce, dan mesin biskuit persik adalah peralatan utama untuk produksinya.

Dapur Pusat

Menyediakan produk biskuit persik standar untuk beberapa toko katering.

Hotel dan Restoran

Sajikan biskuit sebagai dim sum atau hidangan penutup untuk para tamu.

Perusahaan Ekspor

Memproduksi biskuit buah persik untuk diekspor ke negara dan wilayah lain.

Karakteristik Kinerja Cetakan Biskuit Gondor

Cetakan biskuit mengintegrasikan otomatisasi yang efisien, kemampuan penyesuaian yang fleksibel dan karakteristik perawatan yang rendah, cocok untuk produksi komersial skala besar.

Mesin Pencetak Biskuit Gondor – Mitra yang Baik untuk Produksi Biskuit

Mesin cetakan biskuit rotari Gondor, kualitas luar biasa! Ini hemat energi, mudah dioperasikan, dan dapat membentuk secara akurat. Baik itu bengkel kecil maupun pabrik besar, itu adalah pilihan ideal Anda. Percayakan Gondor dan gunakan mesin ini untuk membuka jalan menjual biskuit lezat untuk Anda!