Gondor Pasta Production Lines

Di era sekarang yang mengejar konsumsi berkualitas dan personal, bengkel makanan kecil dan pengusaha terus mencari peralatan produksi yang dapat menyeimbangkan teknologi, efisiensi, dan rasa. Barang baru kami lini produksi pasta kecil dilahirkan untuk tujuan ini. Ini menggabungkan teknologi pembuatan mie tradisional Italia dengan teknologi otomasi modern, memudahkan bengkel Anda untuk meniru cita rasa asli Italia dan menciptakan merek makanan lokal yang kompetitif.

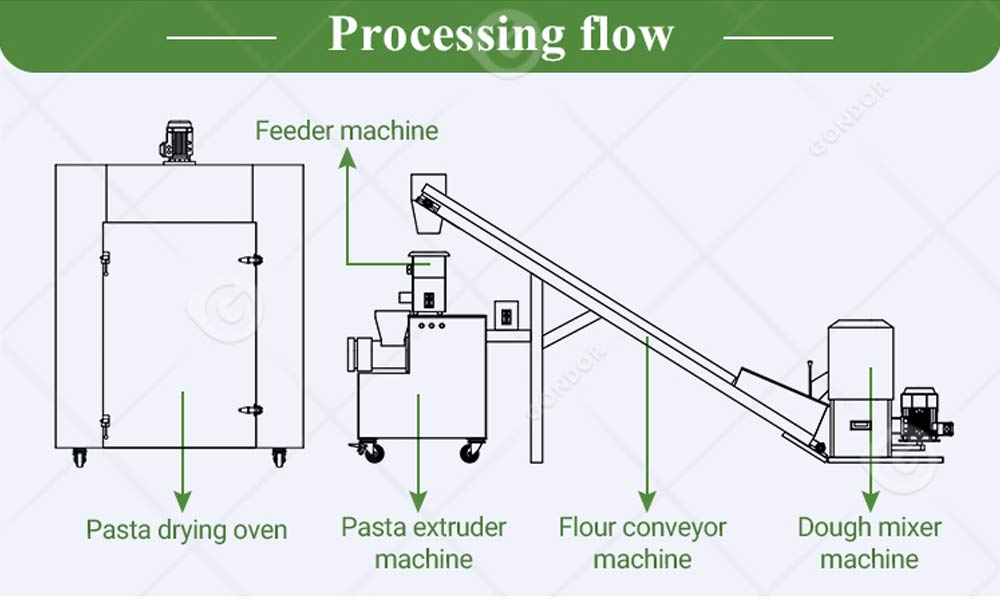

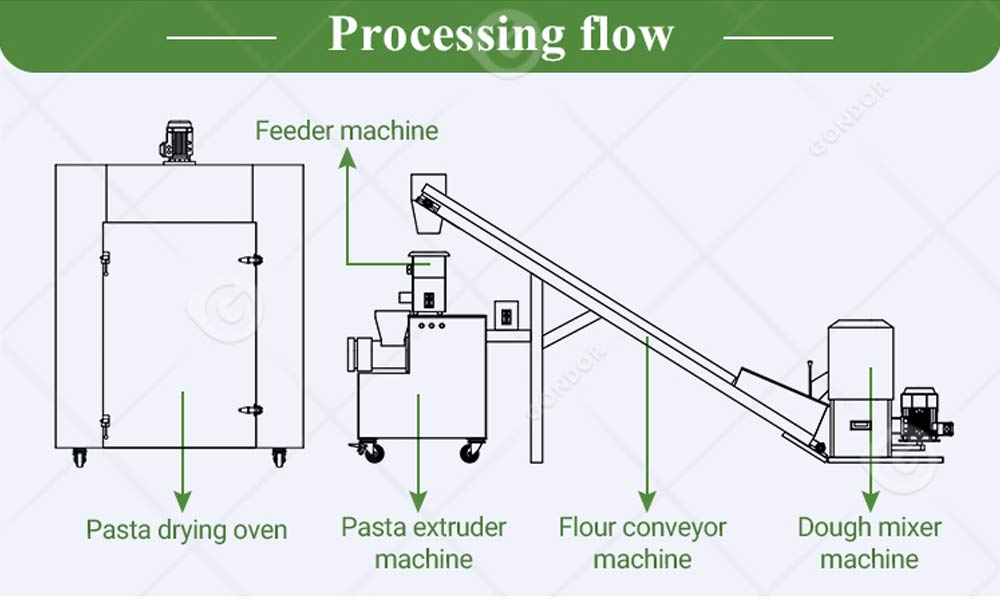

Lini produksi makaroni semi-otomatis ini dirancang khusus untuk usaha makanan kecil dan menengah, dapur pusat, dan lokakarya startup. Seluruh lini terdiri dari pengaduk adonan, konveyor tepung, sistem pemberian makan, ekstruder makaroni, dan mesin pengering. Peralatan ini memiliki struktur yang kompak, tapak kecil, dan pengoperasian yang mudah, mendukung berbagai cetakan dan kapasitas produksi yang dapat disesuaikan untuk mencapai produksi yang sepenuhnya otomatis dari bahan mentah hingga produk jadi.

Small Pasta Production Line Specification

| Nama Mesin |

Voltase |

Kekuatan |

Bahan |

Ukuran |

| Mesin pengaduk adonan |

380V |

3kw |

Baja tahan karat |

900*550*1000mm |

| Mesin konveyor tepung |

220V |

0.35kw |

2800*750*650mm |

| Mesin ekstruder pasta |

380V |

5.5kw |

1100*650*1200mm |

| Oven pengering pasta |

380V |

12kw |

1400*1250:2350mm |

| Mesin pengumpan |

220V |

0.3kw |

650*420*450mm |

Target Pasar Lini Produksi Pasta Potong Panjang

Lini produksi pasta potong panjang adalah pilihan ideal bagi produsen makanan skala kecil dan menengah di seluruh dunia, terutama untuk kelompok pelanggan berikut:

Bantu merek membedakan cita rasa Italia mereka di pasar lokal.

Lokakarya Makanan Startup

Skema peralatan ideal dengan investasi rendah dan pengembalian tinggi.

Digunakan untuk mengembangkan produk pasta pendek dengan bentuk dan rasa yang inovatif.

Meet the demand of fresh noodle making on-site and enhance the customer experience.

Di bawah tren konsumen yang berkembang’ mengejar kesehatan, tekstur buatan tangan, dan rasa segar, jalur produksi kecil ini akan membantu perusahaan meraih peluang pasar.

Karakteristik Peralatan Inti Lini Produksi Pasta Potong Pendek

Pengaduk Adonan

Struktur baja tahan karat diadopsi, dan waktu serta kecepatan pengadukan dapat diatur secara bebas untuk memastikan adonan seragam dan elastis. Dilengkapi dengan jendela visual dan sistem perlindungan keselamatan otomatis, keamanan dan kualitas diperhitungkan.

Konveyor Tepung

Sistem pengangkutan yang tertutup sepenuhnya menghindari polusi sekunder, dan panjang pengangkutan dapat disesuaikan, secara efektif mengurangi tenaga kerja penanganan manual. Hemat energi, efisien, kontinu, dan stabil.

Pengumpan Presisi

- Spiral feeding design realizes high-precision quantitative feeding and ensures a stable and smooth extrusion process.

- Kontrol motor independen dapat secara fleksibel menyesuaikan kecepatan pengumpanan sesuai dengan karakteristik adonan yang berbeda.

ekstruder makaroni

- Peralatan inti dari seluruh lini dapat berupa Extruder satu kepala atau dua kepala.

- Berbagai macam pasta pendek dapat dengan mudah diproduksi dengan mengganti cetakan, termasuk makaroni, penne, Fusili, kupu-kupu, Kerang, dan sebagainya.

- Kepala mesin dilengkapi dengan pemotong putar, yang secara otomatis dapat menyesuaikan panjang dan kecepatan potong untuk mencapai pemotongan yang akurat, bentuk penuh, dan permukaan halus.

Mesin Pengering

- A multi-layer circulating air system can control temperature, kelembaban, dan laju aliran udara secara mandiri.

- Sadarilah proses pengeringan lambat bersuhu rendah, menjaga struktur internal dan rasa pasta semaksimal mungkin, dan mencegah retak dan deformasi.

- Makaroni kering bisa langsung dikemas atau masuk proses pendinginan selanjutnya.

Keuntungan Unik dari Lini Produksi Pasta Kecil

Desain ModularKapasitas yang Dapat DisesuaikanOpsi Multi-CetakanPembentukan Cepat & Keluaran StabilDukungan Profesional:

Itu dapat diperluas secara fleksibel sesuai dengan kebutuhan produksi.

Dari 50kg/jam hingga 300kg/jam, cocok untuk produksi skala yang berbeda.

Mendukung pengembangan bentuk yang dipersonalisasi untuk memenuhi kebutuhan produk kreatif.

Efisiensi tinggi dan konsistensi tinggi.

Menyediakan instalasi dan debugging, formula training, dan layanan purna jual.

Bantuan untuk Menciptakan Rasa Asli Italia

Jika Anda merencanakan proyek pemrosesan pasta yang lengkap, kami juga menyediakan berbagai peralatan pendukung:

Selamat datang untuk menghubungi kami untuk solusi dan penawaran lengkap. Biarkan lini produksi makaroni kecil menjadi langkah pertama bagi Anda untuk menciptakan cita rasa asli Italia dan memperluas pasar global!