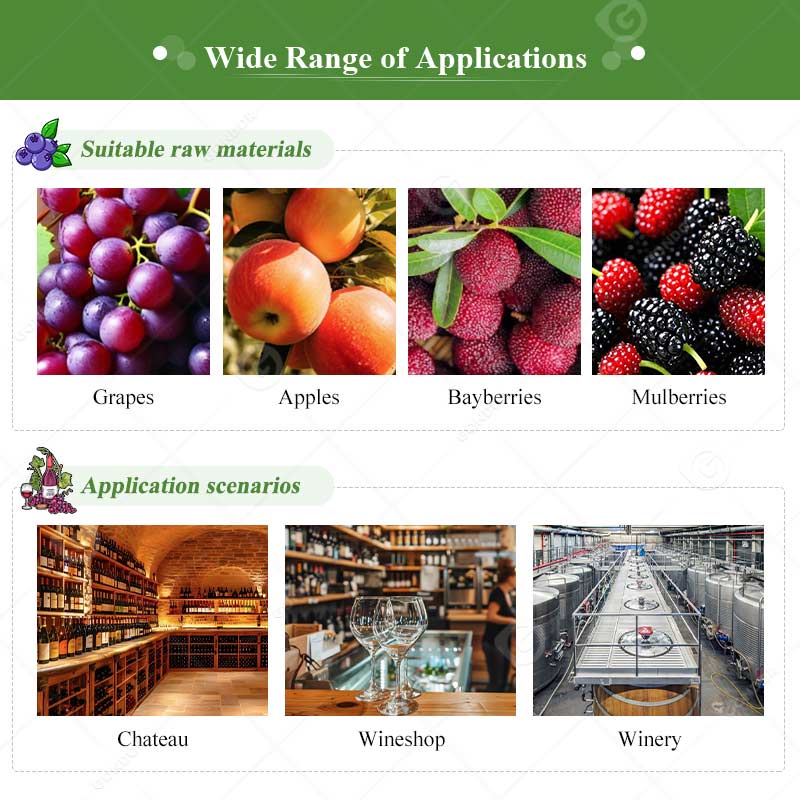

Kita tangki fermentasi anggur adalah titik awal untuk menyeduh anggur berkualitas tinggi. Bukan hanya sekedar perangkat tetapi juga jembatan antara alam dan teknologi, tradisi dan inovasi. Cocok untuk perkebunan anggur besar, perusahaan pembuatan bir skala kecil dan menengah, dan produsen minuman, mendukung kustomisasi yang dipersonalisasi. Peralatannya terbuat dari baja tahan karat, dengan ketahanan korosi yang kuat, ketebalan opsional 2mm hingga 12mm, dan kapasitas 1 hingga ratusan meter kubik, memenuhi kebutuhan skala yang berbeda. Pada saat yang sama, itu banyak digunakan dalam fermentasi, penyimpanan, dan klarifikasi anggur, anggur buah dan minuman lainnya, dan cocok untuk anggur, apel, bayberry, murbai, dan bahan baku lainnya.

|

Jenis |

Diameter | Tinggi silinder | Tinggi keseluruhan |

Volume(Dapat disesuaikan) |

|

GD-200 |

680mm | 610mm | 1000mm | 200L |

| GD-300 | 600mm | 1220mm | 1750mm | 300L |

|

GD-500 |

750mm | 1220mm | 1800mm | 500L |

| GD-1000 | 1050mm | 1220mm | 1850mm |

1000L |

Target Pasar Fermentor Anggur

Fermentor anggur Gondor banyak digunakan di banyak industri yang berkaitan dengan fermentasi karena kinerjanya yang tinggi dan keserbagunaannya. Berikut ini adalah industri sasaran utamanya dan penerapan tipikalnya:

Sorotan Produk Fermentor Anggur Stainless Steel

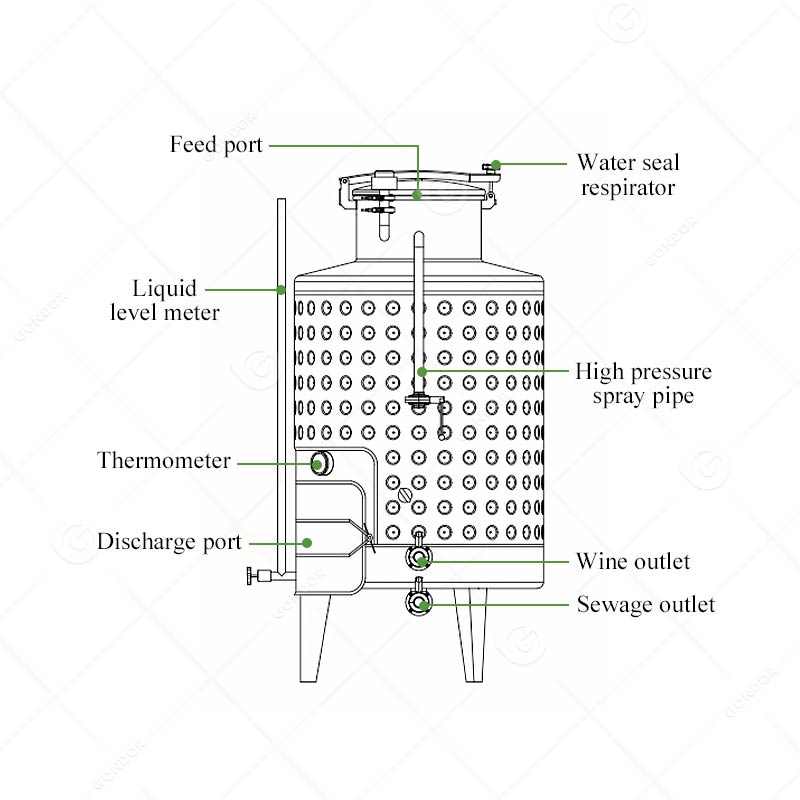

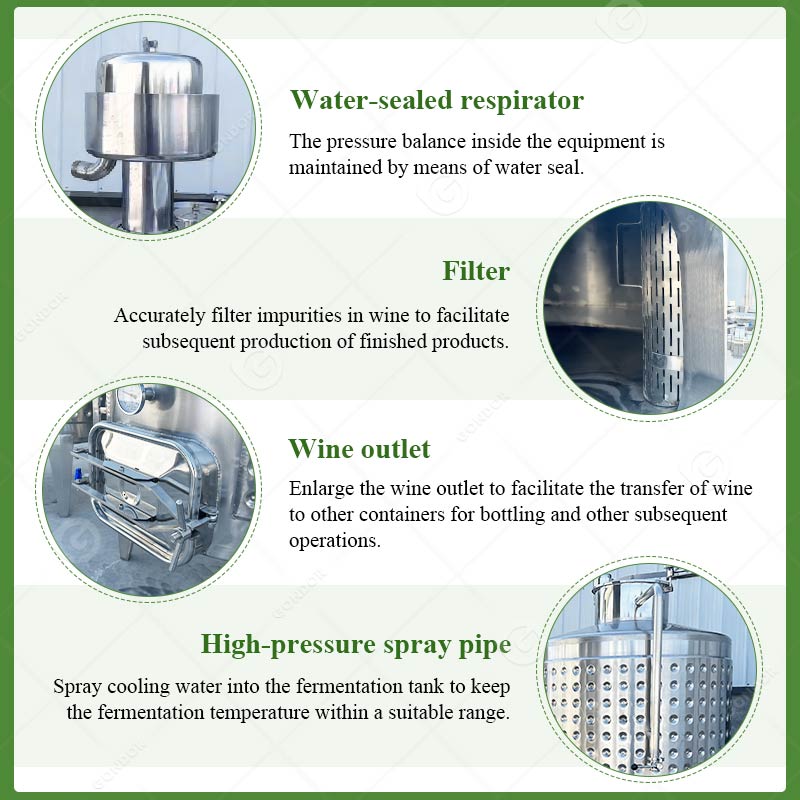

Pipa semprot bertekanan tinggi yang terpasang di dalamnya, melalui sistem sirkulasi air pendingin, mengontrol suhu fermentasi, mencegah inaktivasi ragi, dan mempertahankan rasa buah alami dari anggur.

Proses pemintalan diadopsi di dalam, dengan tepi R-arc dan tidak ada struktur sudut mati, yang sangat mengurangi risiko kontaminasi oleh bakteri lain-lain.

Bagian bawah dilengkapi saluran pembuangan limbah persegi untuk memudahkan pembuangan residu. Termometer memantau fermentasi secara real time untuk pembuatan bir yang stabil. Komponennya mudah digunakan, menyederhanakan pengoperasian dan pemeliharaan.

Pastikan permukaan pengelasan halus dan konsisten, meningkatkan keseluruhan keindahan dan penyegelan peralatan, dan tidak ada duri di dalamnya untuk menghindari perkembangbiakan bakteri.

Saring pomace secara efisien, secara otomatis menyelesaikan pemisahan ampas dan jus, meningkatkan hasil anggur, dan memudahkan pembersihan dan pemeliharaan.

Permukaannya dipoles dengan perawatan permukaan cermin, dengan pola yang konsisten, sambungan solder halus, dan visual dan praktis.

Termasuk outlet anggur, saluran keluar tiupan, katup pengambilan sampel cepat, Perangkat Keseimbangan Tekanan, dll., setiap tempat mencerminkan pertimbangan akhir dari pengalaman penggunaan.

Solusi Pembuatan Minuman Keras Terintegrasi

Tangki fermentasi anggur kami dapat bekerja sama secara lancar dengan a mesin ekstraktor jus buah, mesin pengisian botol, dan peralatan lainnya untuk membangun jalur produksi terintegrasi yang efisien. Jangan ragu untuk menghubungi kami untuk mendapatkan penawaran eksklusif dan layanan yang disesuaikan. Kami tidak hanya menyediakan peralatan berkinerja tinggi, tetapi juga memberikan dukungan teknis profesional untuk membantu Anda membangun merek anggur Anda sendiri!