Automated Pita Bread Production Line

The pita bread production line is a device specially designed for efficient and large-scale production of Pita bread, with a high-yield capacity of 1000 sheets per hour and a zero failure rate. This production line can ensure that every Pita bread has a perfect hollow structure, soft taste, and uniform golden yellow appearance through advanced automation technology and a precise baking control system. Pita bread is suitable for traditional catering needs and meets the needs of the modern fast food and catering industry for efficient and standardized production.

Gondor Pita Bread Production Line

|

სახელი

|

ძალაუფლება |

ძაბვა |

წონა |

ზომა(მმ) |

ტევადობა |

| Horizontal dough mixer machine |

2.2კვტ |

220ვ |

75კგ |

780*530*840 |

25kg/batch

|

|

Dough press machine

|

3კვტ |

220ვ |

230კგ |

1380*610*1260 |

/ |

|

Pita bread making machine

|

3კვტ |

220ვ |

400კგ |

1900*730*1170 |

1500-2000ცალი/სთ

|

|

ლიფტი

|

0.5კვტ |

220ვ |

100კგ |

1000*800*1200 |

/ |

| Baking oven |

1.2კვტ |

220ვ |

640კგ |

2650*950*1080 |

500-1000ცალი/სთ |

|

Cooling machine

|

0.5კვტ |

220ვ |

120კგ |

2500*700*720 |

/ |

Industries in Need of the Arabic Bread Production Line

Efficient production of large quantities of standardized Pita bread,

ensuring stable quality and reducing production costs.

Catering Processing Factory

.

Quickly produce uniform Pita bread to meet the needs of high-demand fast food chains.

Provide standardized bread and stably supply multiple catering units to ensure consistency and quality.

Export and International Market

,

flexibly adjust production,

and enhance international competitiveness.

Quickly produce customized bread to improve food quality and customer dining experience.

With the expansion of the global fast food industry and the increasing demand for Pita bread in the Middle East, Mediterranean, and Asian markets, this production line can help food manufacturers quickly respond to market changes, გააუმჯობესოს წარმოების ეფექტურობა, and occupy an advantageous position in the highly competitive market.

Advantages of Pita Bread Machine

Precision Baking

Three-layer baking technology ensures that the surface color of Pita bread is uniform, the skin is slightly brittle, the heart is soft, and the taste is perfect.

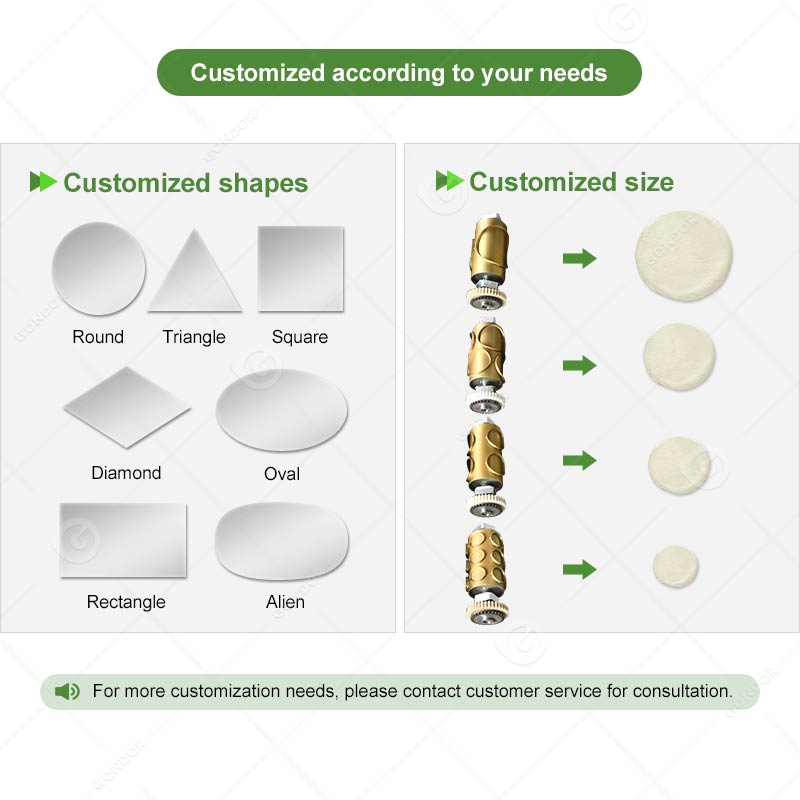

Customizable Shape and Size

The mold can be changed to produce Pita bread with different shapes and sizes to meet the global market demand.

Efficient Productivity

It can produce 1000 sheets per hour, and the zero failure rate ensures efficient and large-scale production and reduces labor costs.

Strict Temperature Control and Fermentation

Accurately control the temperature, ტენიანობა, and fermentation time to ensure that Pita bread has a rich wheat flavor and ideal hollow structure.

Intelligent and Flexible Production

The Flexible adjustment of bread size, thickness, and weight to meet the needs of different markets and customers.

ეფექტური გაგრილების სისტემა

The air dryer quickly cools down to ensure that the bread maintains its best taste and structure.

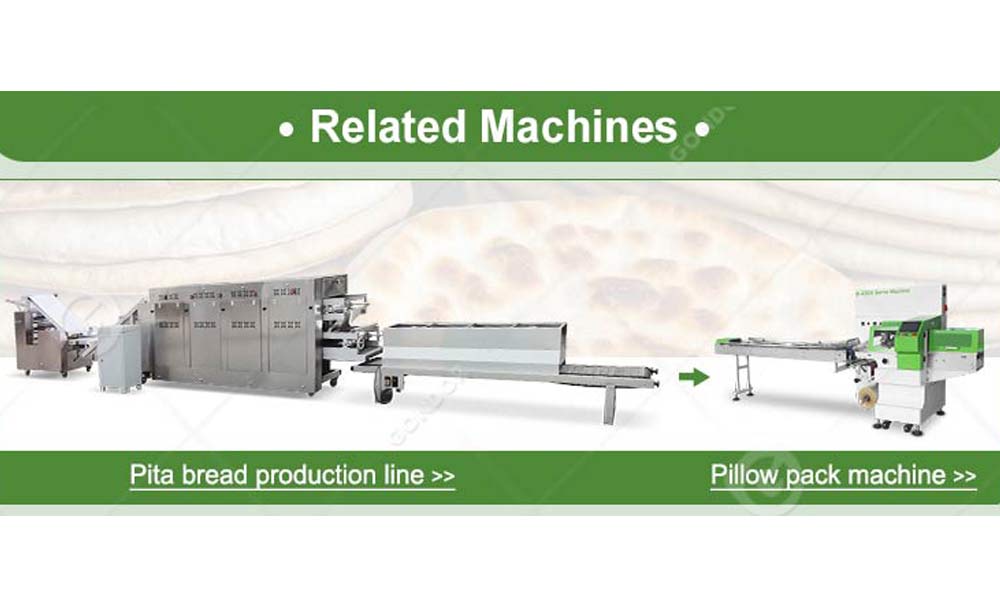

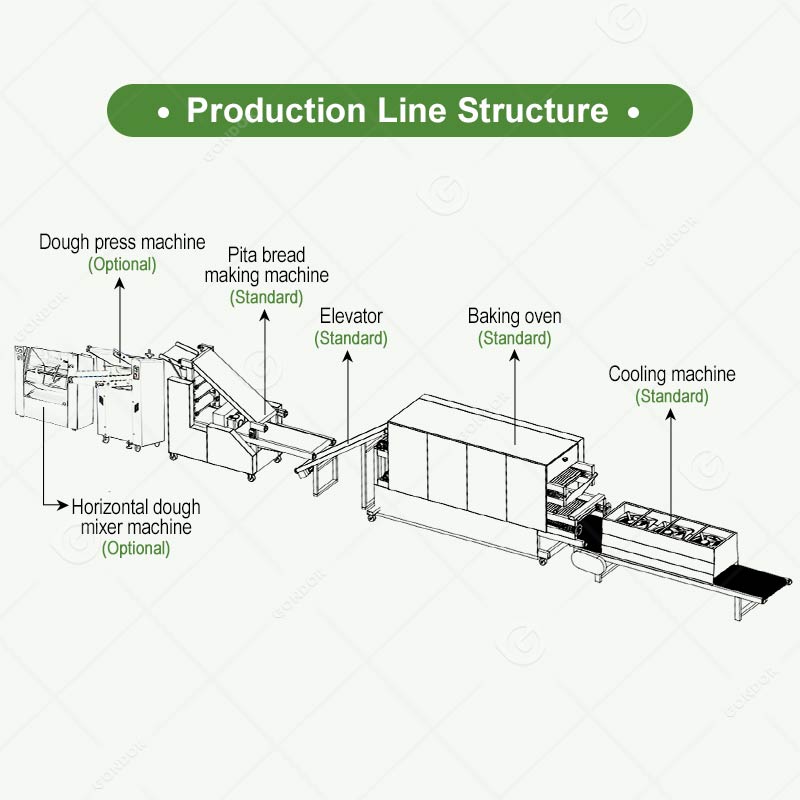

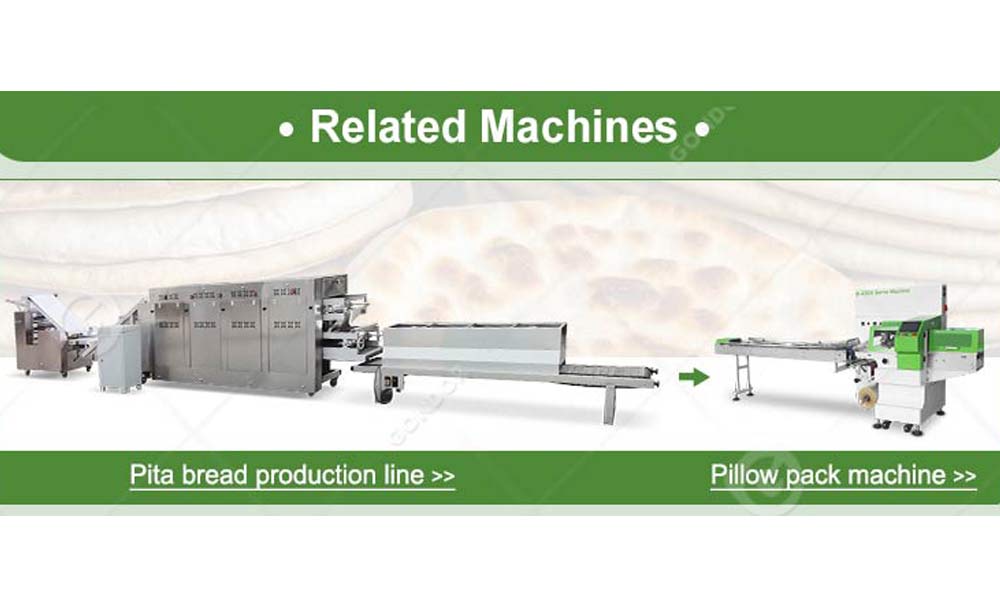

Perfect Matching to Improve Production Efficiency

The pita bread production line is used together with a horizontal dough mixer, dough press, and other equipment to ensure uniform and smooth dough and improve the quality of finished products. Supporting equipment, როგორიცაა ა ბალიშის შესაფუთი მანქანა, can ensure that bread products are in the best condition and convenient for transportation. Whether it is the traditional market or the global catering demand, this production line can provide stable and efficient production capacity for enterprises and help enterprises to occupy an advantage in the market.

Automatic Industrial Pita Bread Line FAQ

1. What is the capacity of the pita bread production line?

.

Depending on the selected model,

its capacity ranges from 500 რომ 5000

pieces per hour.

Please contact us for a customized solution based on your production requirements.

2. How does the pita bread production line ensure consistent product quality?

. უფრო მეტიც,

the automation system reduces human error,

ensuring consistent size and texture.

3. What are the power requirements for this production line?

,

ranging from 15

kW to 80 კვტ.

We provide detailed specifications for each machine and can offer customized power options based on your factory’s specific needs.

4. What materials are used in the manufacture of the pita bread production line?

,

ensuring durability and hygiene.

All food-contact components meet international food safety standards,

ensuring safe and reliable operation.

5. Can the production line be customized to produce pita bread in different sizes?

დიახ,

by simply changing the molds and settings,

the production line can be adjusted to produce pita bread in various sizes,

from mini to large.

We offer flexible machine designs to meet your specific product needs.

6. Can the pita bread production line be integrated with other baking equipment?

დიახ,

our pita bread production line is compatible with a variety of other baking equipment,

including dough mixers,

ovens,

and packaging machines.

We can assist you in designing a complete automated production system to meet your specific needs.