Gondor Çikolata Tava Makinası

Çikolata şeker kaydırma makinesi tabletleri kaplamak için özel olarak kullanılan önemli bir ekipmandır, haplar, vesaire. Dahası, kaplama makinesinin geniş bir kullanım alanı vardır. Farmasötik alanda, ilaçların tadını iyileştirebilir ve ilaç salınımını kontrol edebilir. Gıda endüstrisinde, şekerleri daha güzel ve lezzetli hale getirebilir. Ek olarak, verimli üretim kapasitesi büyük ölçekli ihtiyaçları karşılayabilir, ve farklı kaplama malzemelerine uyum sağlamak için esnek sıcaklık ayarı mevcuttur.

Gondor Şeker Kaplama Makinası

Çikolata Kaplama Kaydırma Makinesi Şartname

| Modeli | Saksı Çapı | Dönme Hızı | Ana Motor Gücü | Üfleyici Gücü | Isıtma teli gücü | Verimlilik | Boyut | Net ağırlığı |

| GDJ-400A | 400mm | 50devir/dakika | 0.37KW | 40K | 1KW | 2-5kg/parti | 770*670*840mm | 70kilogram |

| GDJ-600A | 600mm | 0.75KW | 120K | 2KW | 8-15kg/parti | 930*620*1140mm | 120kilogram | |

| GDJ-800A | 800mm | 1.5KW | 200K | 2KW | 30-50kg/parti | 1100*800*1600mm | 180kilogram | |

| GDJ-1000A | 1000mm | 2.2KW | 250K | 4KW | 50-70kg/parti | 1200*1200*1600mm | 260kilogram | |

| GDJ-1250A | 1250mm | 2.2KW | 370K | 4KW | 80-150kg/parti | 1350*1350*1600mm | 360kilogram |

Gondor Şeker Kaydırma Makinesi Aşağıdaki Pazarlarda Yaygın Olarak Kullanılıyor

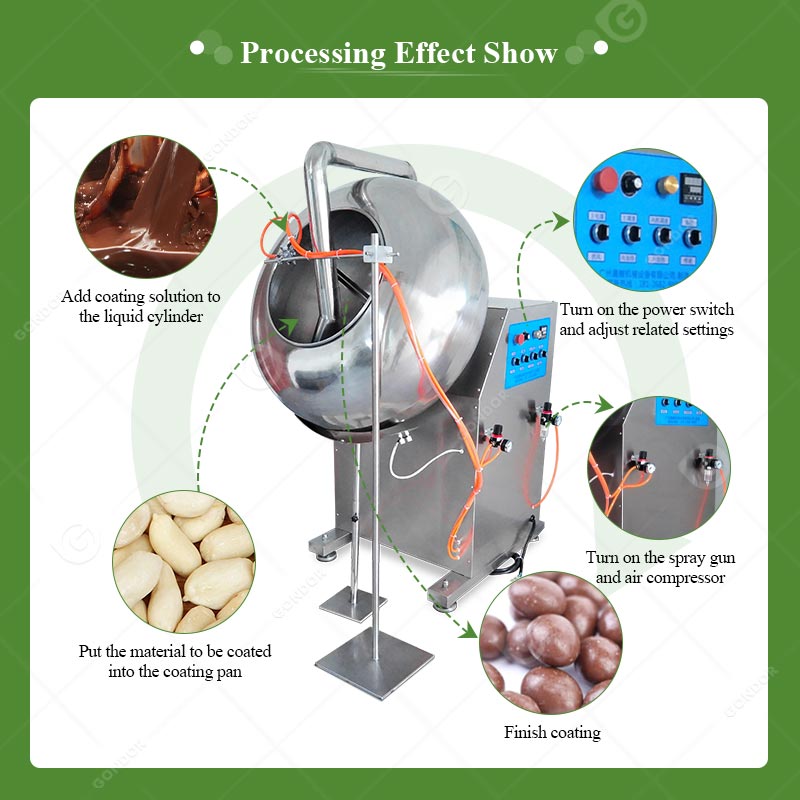

Gondor Şeker Kaplama Makinesi Ürünü

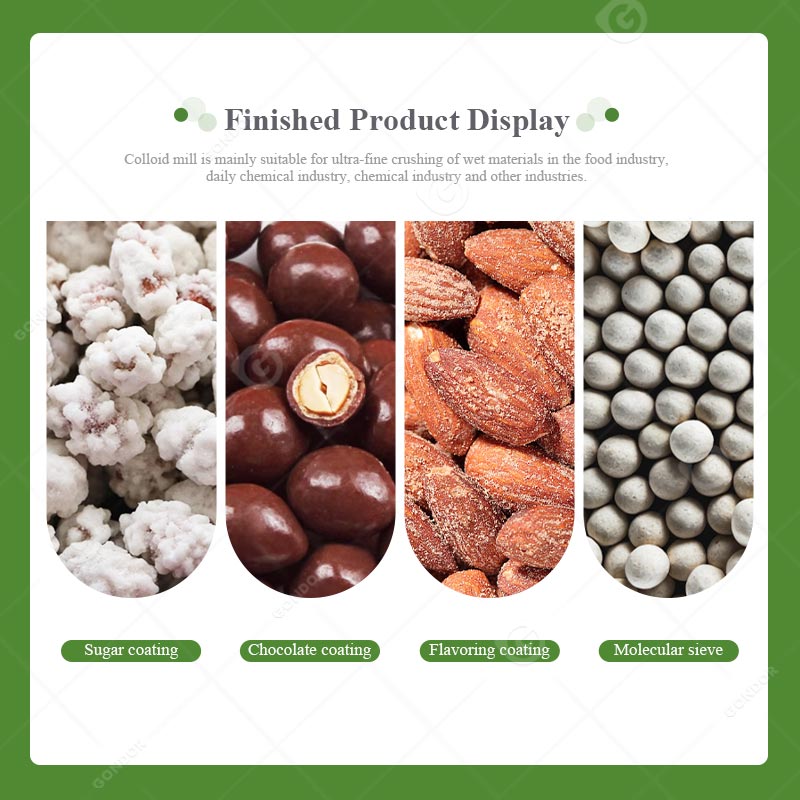

Gondor Şeker Kaplayıcı Bitmiş Ürün

Fıstık Çeşitleri

Çikolata Topları

Gondor Çikolata Tavalama Makinesini Seçmenin Avantajları

Sürekli çalışmayı sağlayabilir ve üretim verimliliğini artırabilir.

Farklı kaplama malzemelerinin gereksinimlerini karşılamak için iç ve dış ısıtma fonksiyonlarıyla.

Tozun uçuşmasını ve kaplama sıvısının buharlaşmasını önleyin, Üretim ortamının temizliğini ve malzeme kullanımını sağlamak.

Kaplamanın homojenliğini sağlamak için kaplama solüsyonunun püskürtme hacmini ve dağılımını doğru bir şekilde ayarlayabilme.

Farklı ölçeklerdeki üretim ihtiyaçlarını karşılayacak farklı kapasite ve boyutlarda modeller bulunmaktadır..

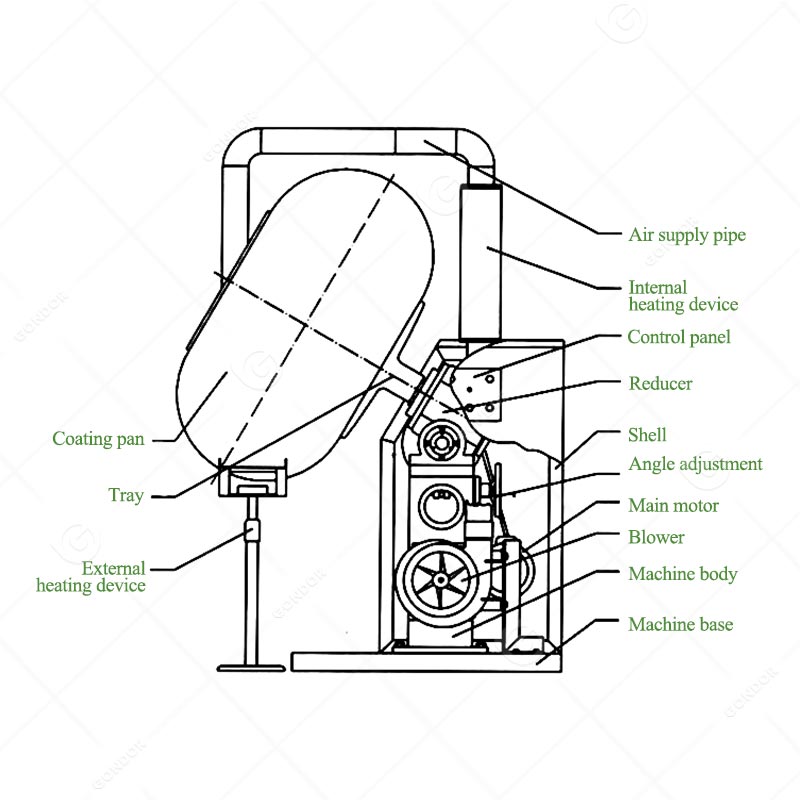

Çikolata Tavalama Makinesi Bileşenleri ve Fonksiyonları

Kaplama Tavası

Tipik olarak küresel, armut şeklinde, veya tambur şeklindeki paslanmaz çelik tava. Malzemelerin yuvarlanma yörüngesini ve karıştırma derecesini kontrol etmek için birden fazla açıda eğilebilir. Dönmesi, malzemelerin karmaşık hareketini sağlayan temel mekanizmadır..

Püskürtme Sistemi:

Bulamaç tankını içerir, pompa, borular, ve püskürtme nozulları. Çikolata ve şurup gibi kaplama sıvısının eşit şekilde atomize edilmesinden sorumludur, şekerin üzerinde ince bir damlacık kaplamasının sağlanması.

Hava Besleme Sistemi:

Bir fan içerir, ısıtıcı, soğutma cihazı, hava filtresi, ve hava kanalı. Kontrollü sıcaklık sağlar (sıcak veya soğuk) ve kaplama katmanını kurutmak veya soğutmak için temiz hava.

Kontrol Sistemi:

Modern kaplama makineleri genellikle PLC veya bilgisayar kontrolünü kullanır.

Operatörler pan dönüş hızı gibi parametreleri hassas bir şekilde ayarlayabilir, sıcaklık, püskürtme süresi, ve tam otomasyona ulaşmak için kuruma süresi, tekrarlanabilir üretim.

Toz Giderme Sistemi:

Tavanın üst kısmındaki hava girişi, kaplama işlemi sırasında oluşan toz ve nemi giderir, temiz bir çalışma ortamı sağlamak.

Gondor Çikolatalı Şeker Kaydırma Makinesi – Yüksek Kaliteli Üretici

Şeker kaplama makineleri için Gondor ile işbirliği, aşağıdaki avantajlardan yararlanacaksınız: gelişmiş teknik destek, düzgün ve stabil kaplama sağlar. Yüksek üretim verimliliği, üretimi artırmanıza ve pazar talebini karşılamanıza yardımcı olur. Yüksek kaliteli satış sonrası hizmet, endişelenmenize gerek kalmamasını sağlar. Şimdi harekete geçin ve Gondor ile kaplamada yeni bir sayfa açın!