Gondor Pide Ekmek Yapma Makinesi

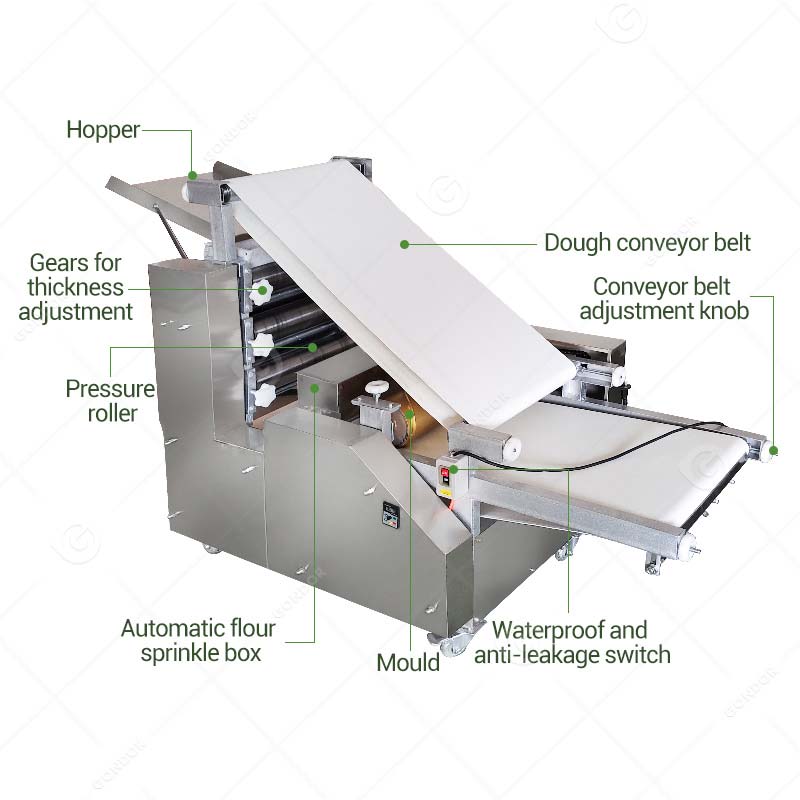

Ticari pide ekmek yapma makinesi çeşitli hamurlar yapmak için kullanılabilir, tortilla gibi, pide ekmeği, chapatti, Arap ekmeği, vesaire. Dahası, Bu pide yapma makinesi, hamurun pürüzsüz ve uzayabilir olmasını sağlamak için yüksek mukavemetli bir hamur presleme silindiri ile donatılmıştır, düzgün kalınlıkta, otomatik pudralama fonksiyonu hamurun yapışmasını önler.

Ek olarak, pide yapma makinesi aynı zamanda hamurun kalınlığını ve üretim hızını ihtiyaca göre ayarlayabilmektedir., ve farklı şekil ve boyutlarda özelleştirilmiş hamurları destekler.

Pide ekmeği yapma makinesinin temel işlevi, hamuru yüksek sıcaklıklarda hızla şişirmektir., bir oyuk oluşturan “cep,” daha sonra doğrudan yenilebilir, dilimlenmiş, veya soğuduktan sonra dolgu olarak kullanılır.

Pide Ekmek Yapma Makinesi Özellikleri

| Modeli | Boyut | Ağırlık | Çıkış | Güç | Hamur tatlısı cilt çapı |

| GD-160 | 1250*450*1050mm | 180kilogram |

3000 adet/saat Ayarlanabilir ve özelleştirilebilir |

2.2kw | D 7-50 santimetre |

Gondor Pide Ekmek Makinası Ticari Ana Talep Alanları

Orta Doğu restoranları, fast food restoranları, sokak yemeği tezgahları, vesaire. Pide ekmeği yaygın bir gıda maddesidir. Bu ekipman, yoğun saatlerde büyük talebi karşılamak için hızlı bir şekilde büyük miktarda Pide ekmeği üretebilir.

Pazarın toptan ve perakende ihtiyacını karşılayacak büyük ölçekli Pide üretimi. Bu makine üretim verimliliğini artırabilir, işçilik maliyetlerini azaltmak, ekmeğin kalite ve hijyen standartlarını sağlamak.

Otelin büfe restoranında, kahvaltı servisi ve diğer senaryolar, Misafirlerin farklı damak zevki ihtiyaçlarını karşılamak için misafirlere taze ve lezzetli Pide ekmeği sunmak amacıyla pide yapma makinelerine ihtiyaç duyulmaktadır..

Fırınlar özel pide ekmeği sağlayacak. Pide ekmeği yapma makinelerinin kullanılması fırınların ürün yelpazesini zenginleştirmesine yardımcı olabilir, daha fazla müşteri çekmek, ve mağazanın rekabet gücünü artırmak.

Sağlıklı beslenmenin peşinde olan bazı aileler için, bu cihaz pratik bir mutfak cihazıdır. Kullanıcılar taze yapabilir, Katkısız Pide ekmeğini kendi damak zevkine ve ihtiyacına göre evde pişirip pişirmenin keyfini çıkarın.

Çok sayıda öğrenci ve çalışana yemek hizmeti sağlanması gerekiyor. Yapma makinesi, kantinin öğretmenlerin ihtiyaçlarını karşılamaya yetecek kadar pide ekmeğini hızlı bir şekilde yapmasına yardımcı olabilir, öğrenciler ve çalışanlar.

Gondor Pide Ekmek Yapma Makinesinin Temel Avantajları

- Tam otomatik çalışma fonksiyonu ile, işçilikten büyük ölçüde tasarruf sağlar, kullanımı basit ve etkilidir, ve üretim verimliliğini artırır.Tam Otomatik

- Hamurun yapışmasını önlemek için gelişmiş otomatik tozlama sistemi ile donatılmıştır, sorunsuz üretim süreci sağlamak, israfı ve operasyon gecikmelerini önleyin.Otomatik Pudralama

- Makinenin hız ve kalınlık ayar fonksiyonları bulunmaktadır., hangi kullanıcıların belirli ihtiyaçlara göre ayarlayabileceği, üretimi daha esnek hale getirmek.Ayarlanabilir Parametreler

- Tamamen paslanmaz çelikten yapılmıştır, su geçirmez ve paslanmaya karşı dayanıklıdır, uzun süreli kullanımda dayanıklılık ve kolay temizlik sağlanması.Dayanıklı Malzeme

- Pürüzsüz ve yumuşak hamur sağlamak için yüksek mukavemetli hamur presleme silindirini kullanın, düzgün kalınlık ve istikrarlı kalite.Yüksek Mukavemetli Hamur Presleme

- Hızlı üretim hızı, üretebilen 60 ile 120 dakikada krep, Büyük ölçekli üretimin ihtiyaçlarını karşılamak.Yüksek Hızlı Üretim

- Farklı şekil ve boyutlardaki hamurlar, farklı ürün gereksinimlerini karşılamak üzere kullanıcı ihtiyaçlarına göre özelleştirilebilir.Çeşitli Özelleştirme

Ticari Pitta Ekmek Yapma Makinesi İş Akışı

Gondor Ticari Pide Ekmek Yapma Makinesi – Üretim Kapasitesini Kolayca Artırmanıza Yardımcı Olur

Üretim verimliliğini büyük ölçüde artırabilecek bir cihaz arıyorsanız, İşçilik maliyetlerinden tasarruf edin ve tutarlı ürün kalitesi sağlayın, Gondor pide yapma makinesi ideal seçiminizdir! Yüksek mukavemetli hamur merdaneleri ile, otomatik tozlama sistemi ve esnek kalınlık ayar fonksiyonu, bu makine üretebilir 3000-6000 Büyük ölçekli üretimin ihtiyaçlarını karşılamak için saatte pide ekmeği. Ekipmanlarımız size istikrarlı ve kaliteli bir Pide ekmeği yapma deneyimi sunacaktır., işletmenizin daha yüksek bir seviyeye çıkmasına yardımcı olmak. Şimdi sipariş verin ve başarıya doğru ilerleyin!