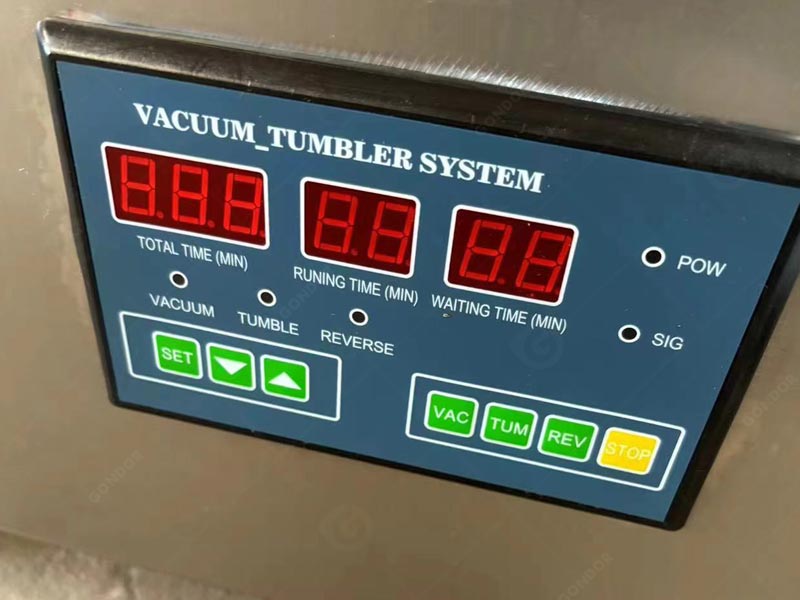

Ticari vakumlu et tumbler marinatör , vakumlu dekapaj makinesi olarak da bilinir, öncelikle çok çeşitli etlerin işlenmesinde kullanılır, sığır eti dahil, kuzu, tavuk, ördek, Kaz, domuz eti, ve balık. Ek olarak, çeşitli sebze ve meyvelerin baharatlanması ve salamura edilmesi için uygundur. Paslanmaz çelik gövdesi ile, kararlı çalışma, geniş yuvarlanma kapasitesi, ve kullanım kolaylığı, bu makine birçok avantaj sunuyor. Yuvarlanarak, karıştırma, ve masaj yapmak, tamburlama makinesi dekapaj sıvısının eşit şekilde emilmesini sağlar, ette mükemmel su tutma ve bağlanma gücü sağlar, böylece hem esnekliğini hem de tadını arttırır. Üstelik, vakum altında çalışmak gıdanın tazeliğinin korunmasına yardımcı olur. Tam otomatik kontrol sistemi verimliliği daha da artırır, kullanıcıların yuvarlanma süresi gibi parametreleri ayarlamasına olanak tanır, aralık süresi, ve çeşitli işleme ihtiyaçlarını karşılamak için ileri veya geri dönüş.

| Modeli | Kapasite(kg/tank) | Güç(kw) | Ağırlık(kilogram) | Makine Boyutu (mm) |

| GR-30 | 15 | 0.75 | 70 | 850*360*780 |

| GR-50 | 25 | 0.95 | 100 | 906*500*808 |

| GR-100 | 50 | 1.3 | 150 | 1060*600*980 |

| GR-200 | 70 | 2.25 | 240 | 1400*800*1280 |

| GR-300 | 100 | 2.25 | 260 | 1410*1000*1450 |

| GR-500 | 240 | 2.25 | 300 | 1500*1020*1640 |

| GR-600 | 225-300 | 2.25 | 350 | 1560*1020*1640 |

| GR-800 | 300-400 | 2.95 | 460 | 1800*1200*1600 |

| GR-1600 | 600-800 | 3.75 | 975 | 2150*1330*2000 |

| GR-2000 | 750-1000 | 3.75 | 1090 | 2200*1440*2010 |

| GR-2400 | 1200 | 5 | 1300 | 2400*1500*2100 |

Gondor Vakumlu Et Tumbler'ın Geniş Pazar Uygulamaları

Gondor Ticari Vakumlu Et Tumbler'ın Önemli Rekabet Avantajları

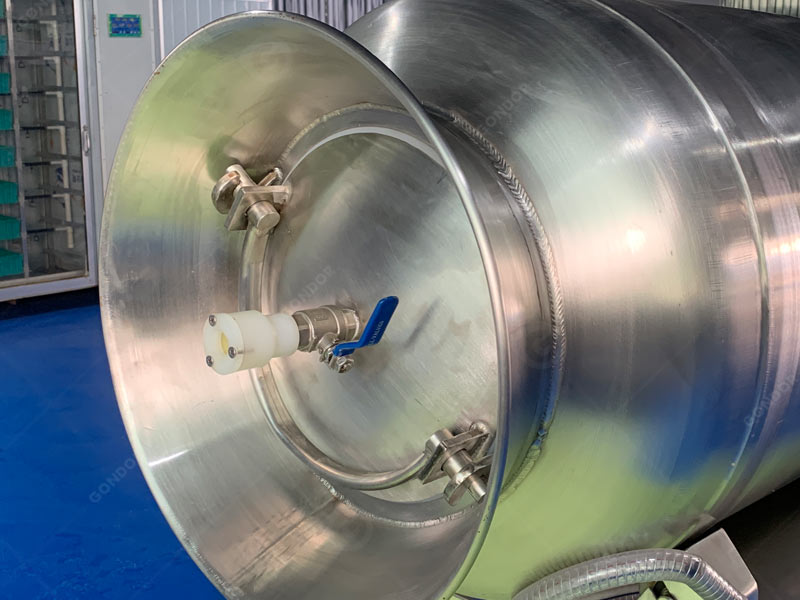

Paslanmaz çelik malzeme kullanılmıştır, hangisi dayanıklı, korozyon önleyici ve pas önleyici, Gıda işlemede hijyenin ve ekipmanların uzun süreli kullanımının sağlanması.

İyi tasarlanmış, kararlı çalışma, yüksek yük altında uzun süre çalışabilir, ve büyük işleme tesislerinin ihtiyaçlarını karşılar.

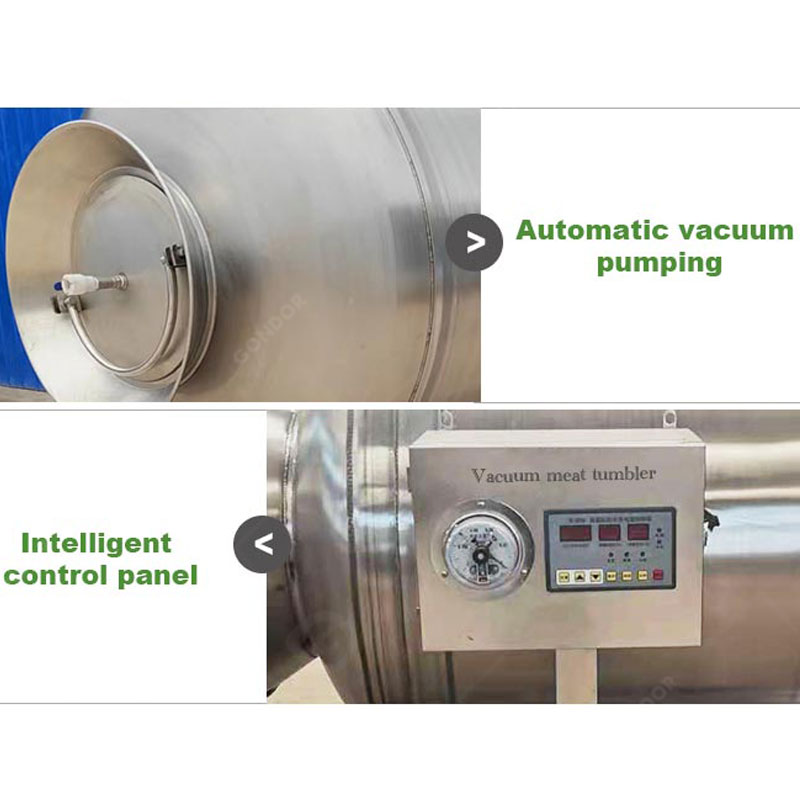

Su geçirmez bir bilgisayar kontrol sistemi ile donatılmıştır, haddeleme ve yoğurma modunu otomatik olarak ayarlayabilir, Kullanımı basit olan ve işçilik maliyetlerini azaltan.

Yuvarlama ve yoğurma alanı büyüktür, Aynı anda çok miktarda yiyeceği işleyebilen, Toplu üretime uygundur ve işleme verimliliğini artırır.

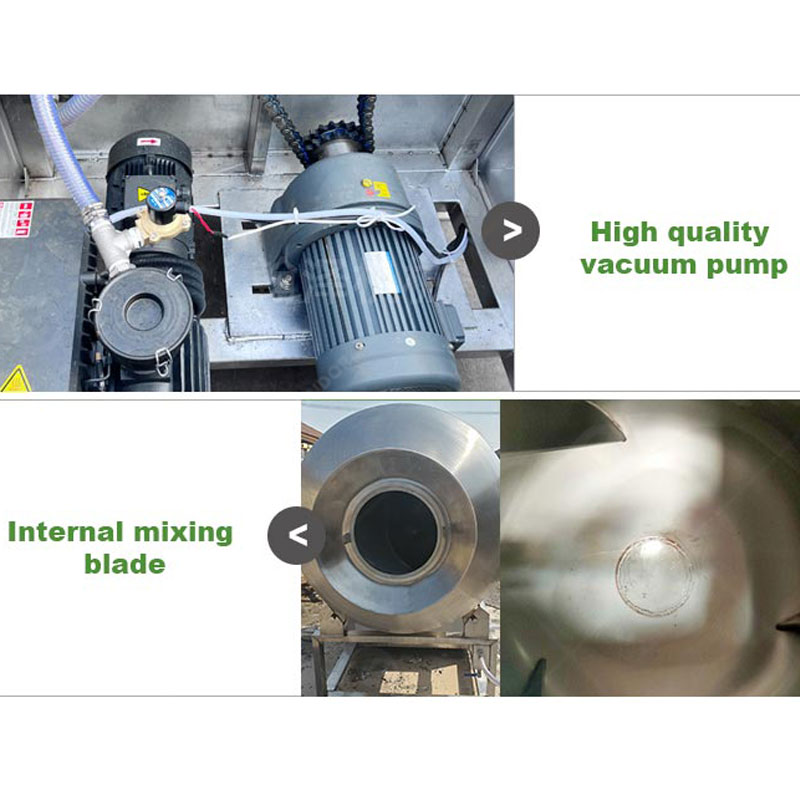

Kürek bıçağının kavisli tasarımı, turşunun eşit şekilde dağıtılmasını sağlar, gıdanın görünümünü korur, ve bitmiş ürünün yumuşaklığını ve su tutma özelliğini artırır.

Frekans dönüşümü gibi birden fazla modu destekler, tersine çevirme, ve boşaltma, ve farklı ürünlere göre haddeleme ve yoğurma hızını ve modunu ayarlayabilir.

Elektrik kesintisi hafıza fonksiyonu ile donatılmıştır, Kesintisiz üretim sağlamak için beklenmedik bir elektrik kesintisinden sonra haddeleme ve yoğurma işlemi yeniden başlatılır.

Vakum ortamında yuvarlama ve yoğurma, bileşenlerin nemini ve beslenmesini etkili bir şekilde koruyabilir, etin yumuşak ve lezzetli olmasını sağlamak.

Verimli ve Yüksek Kaliteli Vakum Silindiri – Et İşleme için En İyi Seçim

Etinizin kalitesini artıracak ekipman arıyorsanız, sebze, veya meyve işleme, ticari vakumlu et tamburlu marinatörlerimiz ideal çözümdür! Yüksek kaliteli paslanmaz çelikten üretilmiştir, bu makineler akıllı kontrollere ve kapanma hafıza fonksiyonuna sahiptir, asitleme sıvısının vakum ortamında iyice emilmesini sağlamak. Bu, su tutulmasını önemli ölçüde artırır, esneklik, ve ürünün tadı. Üstelik, çeşitli uygulamalar için mükemmeldirler, jambon dahil, sosis, ve hızlı dondurulmuş gıdalar, maliyetleri düşürürken üretim kapasitesinin artırılmasına yardımcı olmak. En yeni modellerimiz ve özel fiyatlarımız hakkında daha fazla bilgi edinmek için sizi şimdi bir e-posta veya soruşturma göndermeye davet ediyoruz.. Size kapsamlı ürün çözümleri ve destek sunmak için buradayız!