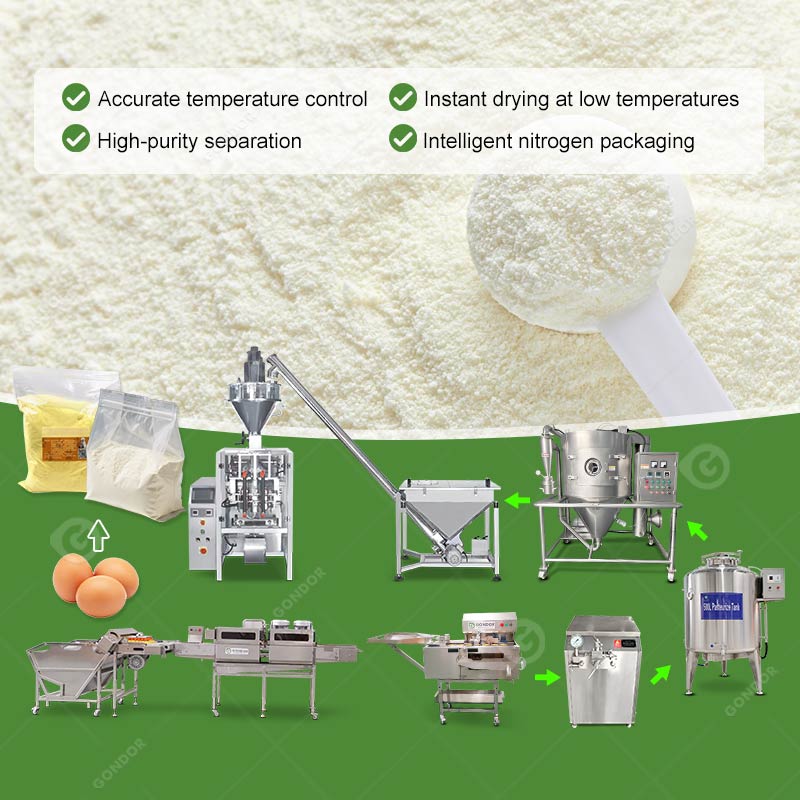

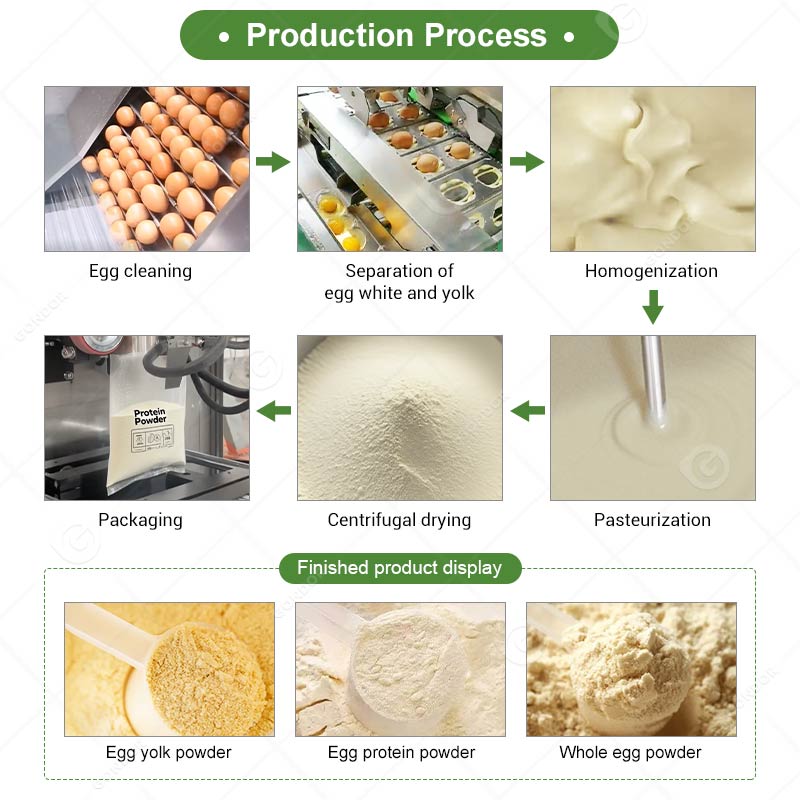

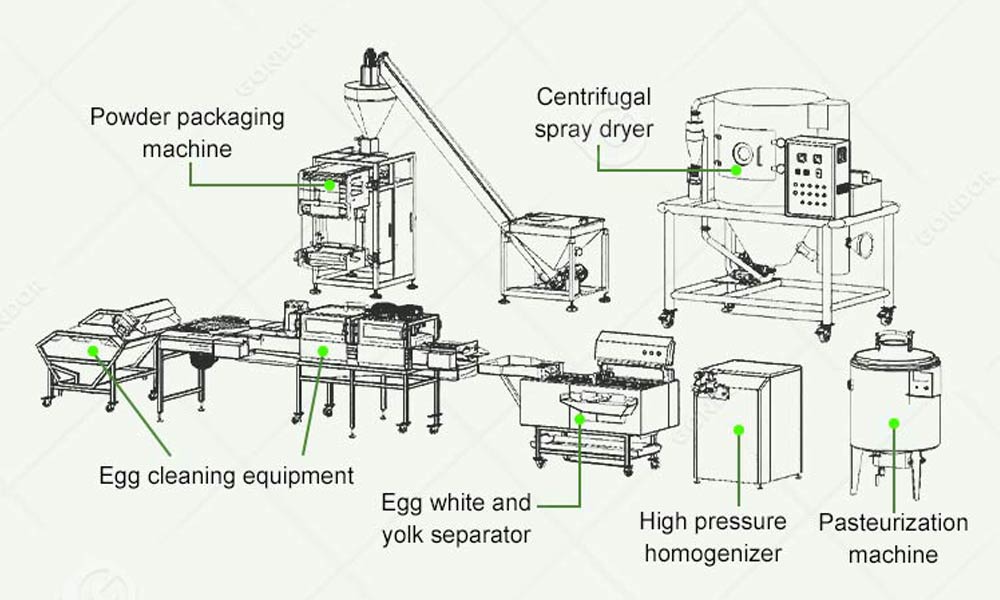

The yumurta tozu üretim hattı gelişmiş bir, Taze yumurtaları yüksek kaliteli yumurta tozuna dönüştürmek için özel olarak tasarlanmış otomatik sistem. Hassas sıcaklık kontrolü sayesinde, yüksek saflıkta ayırma, ve düşük sıcaklıkta sprey kurutma, sistem yumurta tozunun besin değerini ve işlevselliğini tamamen korur. Tüm seri yumurta temizleme gibi birçok prosesi entegre ediyor, ayrılma, homojenleştirme, pastörizasyon, ve akıllı paketleme. Öyleyse, büyük gıda işletmeleri ve besin takviyesi üreticileri için çok uygundur. Ek olarak, bu sistem sıradan yumurtalara esnek bir şekilde uyarlanabilir, selenyumla zenginleştirilmiş yumurtalar, veya organik yumurta. Nihayet, yumurta akı tozu, yumurta sarısı tozu, bütün yumurta tozu, ve çeşitli özelleştirilmiş protein tozu ürünleri üretilebilir.

| Makine Adı | Gerilim | Güç | Malzeme | Boyut |

| Yumurta temizleme ve kurutma makinası | 220V | 2.1kw | Paslanmaz çelik | 2840*550*1400mm |

| Yumurta akı ve sarısı ayırıcı | 220V | 0.4kw | 1700*980*1280mm | |

| Yüksek basınçlı homojenleştirici | 220V | 2.2kw | 755*520*935mm | |

| Pastörizasyon makinesi | 380V | 9kw | 1400*800*1400mm | |

| Santrifüj sprey kurutucu makinesi | 380V | 17.5kw | 2000*900*1900mm | |

| Vidalı toz dolum makinası | 220V | 2.2kw | 1424*980*1343mm |

Yumurta Tozu Üretim Hattının Piyasa Uygulaması

Protein tozuna olan küresel talebin artmasıyla birlikte, yüksek besin değeri, iyi çözünürlük, ve çok işlevli özellikler, çok sektörlü uygulamaların genişlemesini teşvik ediyor. Protein tozu üretim hattı, işletmelerin aşağıdaki alanlardaki ihtiyaçları doğru bir şekilde karşılamasına yardımcı olabilir::

Yumurta Tozu Yapma Makinesinin Üstün Avantajları

Neden Gondor Peynir Altı Suyu Proteini Üretim Hattını Seçmelisiniz??

- Esnek Genişleme: Büyük işletmelerin küçük ve orta ölçekli kapasite gelişimini veya otomasyon dönüşümünü destekleyebilir.

- Geniş Adaptasyon: Gıdaya uygun, besin takviyeleri, kozmetik, ve diğer endüstriler.

- Hammaddelerin Uyumluluğu: Çeşitli yumurta ham maddelerini işleyebilir ve farklı formlarda son ürünleri esnek bir şekilde üretebilir.

- Standart Uyumluluk: Uluslararası kalite ve güvenlik standartlarına uygundur ve ihracat sertifikasyonunu kolaylıkla karşılar.

- Sürdürülebilir Kâr: Otomasyon yoluyla istikrarlı üretim gerçekleştirin, maliyetleri önemli ölçüde azaltmak, ve verimliliği artırın, önemli getirilerle.

Ekipman Önerisi

Müşterilerin üretim sistemini daha da geliştirmelerine yardımcı olmak, ayrıca başka ekipmanlar da sağlıyoruz, örneğin:

- Süt Tozu Üretim Hattı

- Otomatik Kartonlama Makinesi

Bu sistemleri entegre ederek, fabrikanız, çeşitli hammaddeleri ve küresel pazar talebini karşılamak için daha kapsamlı bir protein tozu işleme çözümünü hayata geçirebilir. İster gıda işleme endüstrisinde olun, besin takviyeleri endüstrisi, veya kozmetik endüstrisi, bu üretim hattı size verimli sonuçlar verebilir, güvenilir, ve sürdürülebilir üretkenlik.