Dondurma Külahı Pişirme Makinesi

Yüksek kaliteli dondurma ürünlerine olan küresel talep artmaya devam ederken, güvenilirliğe olan ihtiyaç da öyle, verimli koni üretimi. The tam otomatik dondurma külahı yapma makinesi Saatlik kapasitesi 100.000'in üzerinde olan verimli ve akıllı bir gıda işleme ekipmanıdır. 1,000 parçalar. Ve çeşitli özelliklerde ve şekillerde yumurta tepsilerinin üretimini destekleyebilir. Dahası, makine, yumurta tepsilerinin güzel bir görünüme ve çıtır bir tada sahip olmasını sağlamak için hassas kalıplar ve otomatik kontrol sistemleri kullanır.

Ek olarak, Otomatik dondurma külahı makinesi geniş bir uygulama alanına sahiptir ve dondurma işleme tesisleri için uygun olabilir, gıda fabrikaları, catering şirketleri, ve diğer endüstriler, Verimli üretim elde edilmesine ve pazarın farklı ihtiyaçlarının karşılanmasına yardımcı olabilecek!

Tam Otomatik Dondurma Külahı Yapma Makinesi Özellikleri

| Modeli | Kapasite | Güç | Gerilim | Isıtma Yöntemi | Boyut |

| GD-FACM-40 | 1200-1400adet/saat | 18kw | 380v | Elektrikli ısıtma | 1200*1600*2080mm |

| GD-FACM-60 | 1800-2000adet/saat | 25kw | 380v | Elektrikli ısıtma | 1180*1810*2120mm |

Otomatik Dondurma Koni Makinesi Uygulanabilir Endüstri

Gıda işleme endüstrisinde, Gondor otomatik dondurma külahı makinesi, yalnızca yüksek üretim verimliliği ve akıllı kontrol sistemiyle değil, aynı zamanda tutarlı kalitede çeşitli şekillerde külah üretme yeteneğiyle de öne çıkıyor. Bu nedenle, ekipman, gıda işleme endüstrisinin birçok sektöründe yaygın olarak kullanılmaktadır. Dahası, dünya çapında büyük ölçekli üretim veya özelleştirilmiş siparişler için güvenilir ve verimli çözümleri özelleştirebiliriz. Aşağıda bu makinenin yaygın olarak uygulandığı endüstrilere genel bir bakış bulunmaktadır..

Dondurma üreticilerine uygulanabilir, büyük soğuk içecek fabrikaları, zincir markalar, vesaire., Yumurta konisi ürünlerinin istikrarlı kalitesini ve güzel şeklini sağlamak için, ve üretim verimliliğini artırın.

Çeşitli gıda ambalajlarına yönelik yumurta tepsileri veya külahların üretimine uygundur, waffle külahları gibi, gofret konileri, vesaire., Pazarın farklı ürün ihtiyaçlarını karşılamak için.

Fırın fabrikalarına uygulanabilir, fırın zinciri markaları, vesaire., külah gibi fırınlanmış ürünlerin seri üretiminde kullanılabilir, tatlılar ve soğuk içecekler için ideal kaplar sağlar.

Dondurma dükkanlarına uygulanabilir, tatlı dükkanları, kafeler, vesaire., Günlük satış ihtiyaçlarını karşılamak için hızlı bir şekilde yüksek kaliteli yumurta tepsileri üretebilir.

Gıda toptancıları için geçerlidir, ihracatçılar, vesaire., İstikrarlı ürün kalitesini sağlamak ve küresel pazara toplu satışları kolaylaştırmak.

McDonald's'a uygun, DQ, ve diğer zincir markalar, Birleşik bir marka imajı sağlamak için standartlaştırılmış yumurta tepsisi ürünleri sağlamak.

Kişiselleştirilmiş ürünlere yönelik pazar talebini karşılamak ve farklılaştırılmış marka gelişimine yardımcı olmak için farklı şekil ve desenlerde özelleştirilebilir yumurta tepsileri.

Dondurma Külahı Yapma Makinesi İş Akışı

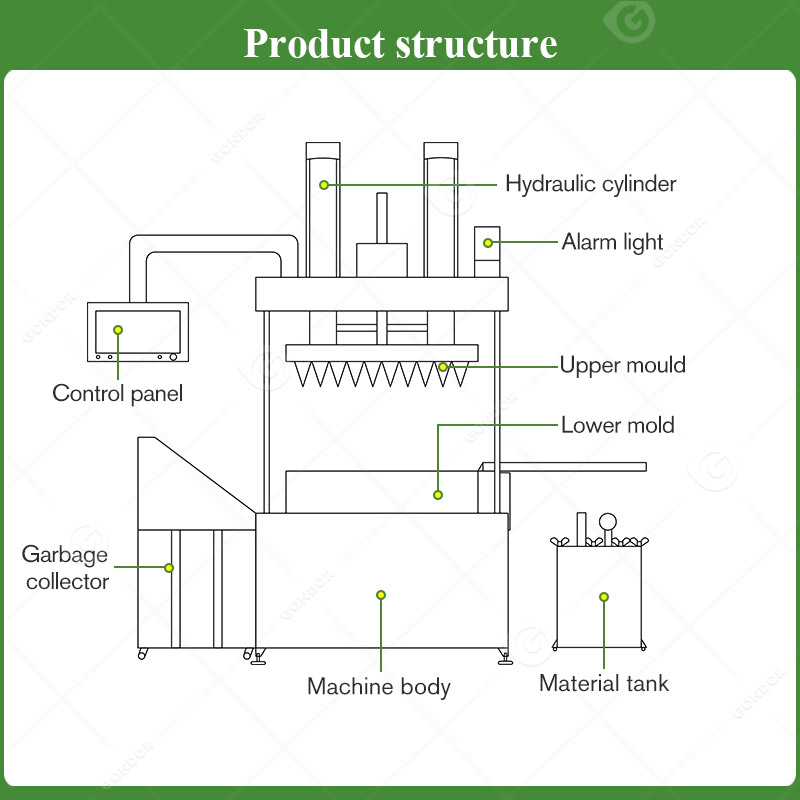

Otomatik Dondurma Külahı Yapma Makinesi, hamur karıştırmayı otomatik olarak tamamlayan, PLC kontrolü altında eksiksiz bir üretim hattıdır., kantitatif dökme, kalıp pişirme, sıcak presleme, kalıptan çıkarma, ve otomatik istifleme.

Gondor Tam Otomatik Dondurma Külahı Yapma Makinesi Üretimi Kolaylaştırıyor

Üretiminizi Yükseltmenize Yardımcı Olacak Daha Fazla Gıda İşleme Ekipmanı

Tam otomatik yumurta tepsisi makinesine ek olarak, ayrıca bir dizi ürün sunuyoruz gıda işleme ekipmanları, örneğin:

İşletmenizin büyüklüğü ne olursa olsun, Üretkenliğinizi artırmanıza ve pazar payınızı genişletmenize yardımcı olacak doğru çözümü sağlayabiliriz. Gıda üretiminizi daha akıllı ve verimli hale getirmek için ayrıntılı teklifler ve teknik destek için bizimle iletişime geçmekten memnuniyet duyarız.!