Hidrolik Sosis Dolum Makinası

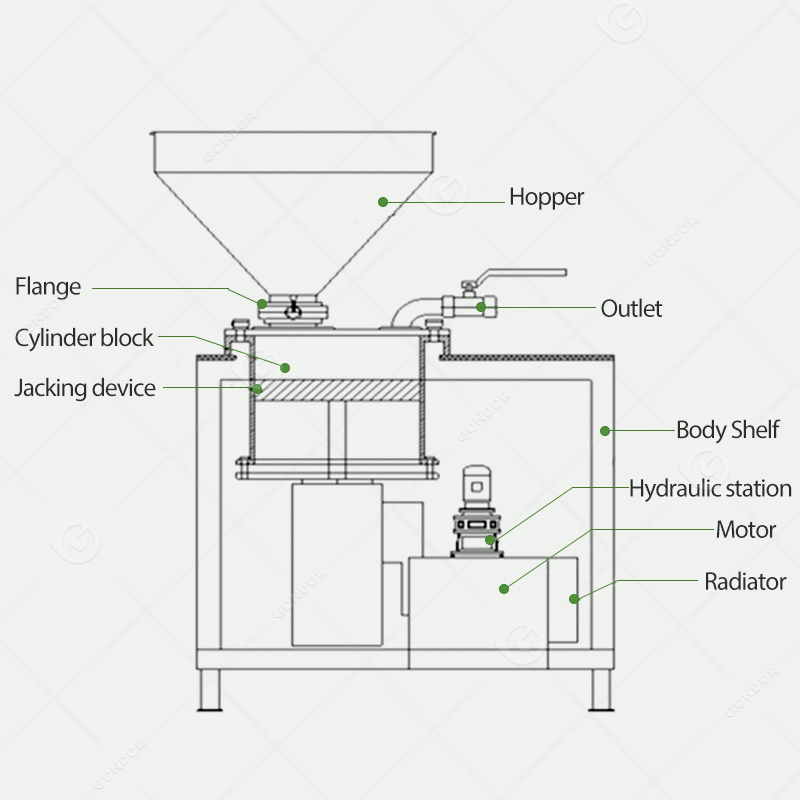

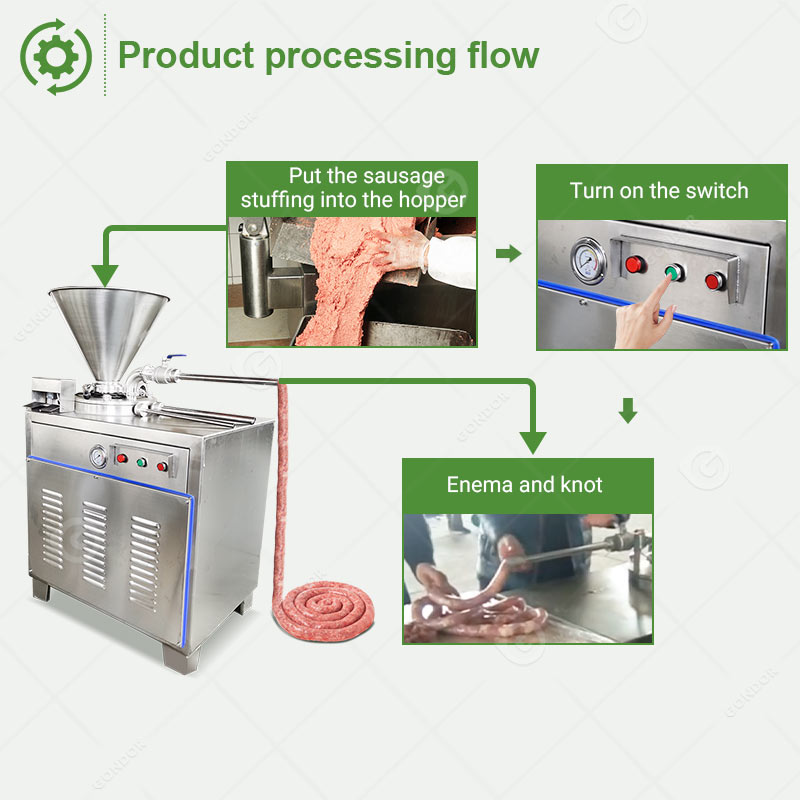

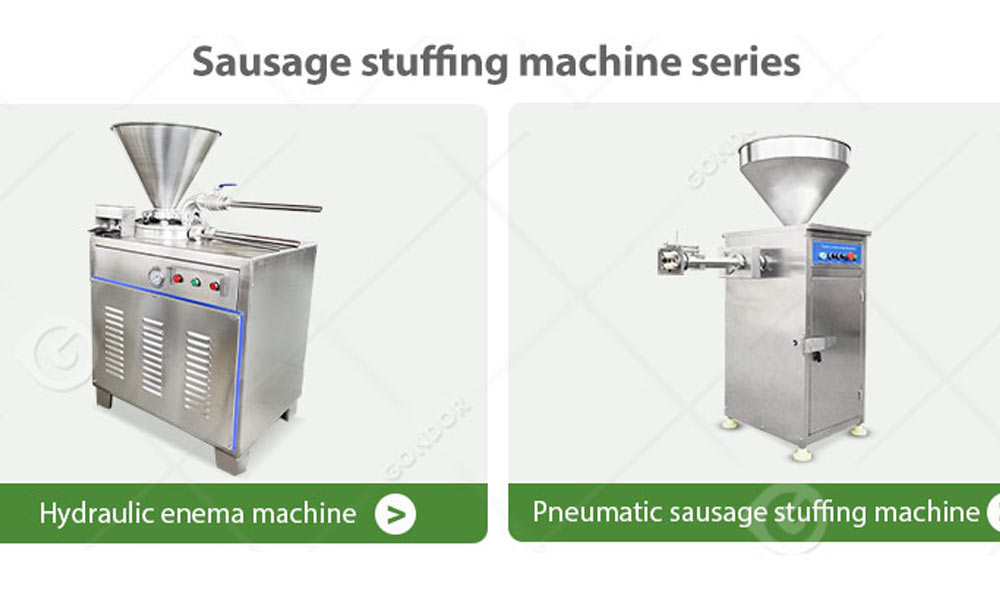

Hidrolik sosis dolum makinası yaygın bir sosis doldurma ekipmanıdır. Esas olarak bir hazneden oluşur, bir hidrolik sistem, sosis doldurma tüpü ve diğer parçalar. Sosis doldurucuyu pompalayan bir hidrolik istasyon benimser, Yaygın olarak kullanılan ve bakım oranı düşük olan, ve müşteriler tarafından derinden seviliyor. Dahası, ekipmanın kullanımı kolaydır, hızlı ve düzgün bir sosis doldurma hızına sahiptir, ve üretim verimliliğini büyük ölçüde artırabilir. Çeşitli sosis türlerinin işlenmesi ve üretimi için uygundur., Hem küçük gıda işleme tesislerinde hem de büyük işletmelerde yaygın olarak kullanılabilir.. Ek olarak, hassas kontrolü her sosisin istikrarlı kalitesini garanti eder, Gıda işleme endüstrisine kolaylık sağlayan ve sosis yapımında güçlü bir yardımcı olan.

| Modeli | Gerilim(v) | Çıkış(kg/saat) | Güç(kw) | Boyut(mm) | Ağırlık(kilogram) |

| GD-30 | 220/380 | 300 | 2.2 | 800*650*1280 | 240 |

| GD-32 | 220/380/110 | 300 | 0.75 | 1500*565*1300 | 240 |

| GD-50 | 220/380/110 | 500 | 1.5 | 1020*730*1500 | 400 |

Gondor Hidrolik Lavman Makinesinin Ana Hizmet Sektörleri

Hidrolik Sosis Doldurucuyla Üretimi Maksimuma Çıkarma

Üretim hattınıza hidrolik sosis doldurma makinesini entegre etmek benzersiz verimlilik ve tutarlılık sağlar. Bu tür sosis doldurma makinesi, ince emülsiyonlu sosisli sandviç dolgularından daha iri taneli sosisli sandviç dolgularına kadar büyük miktarlardaki farklı karışımların işlenmesinde mükemmeldir., minimum ürün kaybı veya hava boşluğu ile daha tıknaz sosis tarifleri. Sabit, Hidrolik sosis doldurma makinesinin güçlü basıncı, her kasanın eşit şekilde doldurulmasını sağlar, tutarlı bir dokuya sahip sosislerle sonuçlanır, dış görünüş, ve ağırlık. Bu yalnızca çıktınızı artırmakla kalmaz, aynı zamanda nihai ürünlerinizin genel kalitesini ve pazarlanabilirliğini de önemli ölçüde artırır..

Gondor Sosis Dolum Makinesinin Mükemmel Verimlilik Avantajı

Mobil gövde tasarımı, kolay ve esnek çalışma. Makine düşük gürültü ve yüksek verimle çalışır. Azaltılmış iş yoğunluğu ve geliştirilmiş iş verimliliği.

Farklı çap ve uzunluktaki muhafazalara uyum sağlar, ve çeşitli dolgu türleri. Farklı müşterilerin ihtiyaçlarını karşılayabilir ve gıda işleme şirketlerine daha fazla seçenek ve esneklik sağlayabilir..

Ekipmanın malzemelerle temas eden kısmı metalden yapılmıştır 304 paslanmaz çelik, hangisi güvenli, hijyenik, ve korozyona dayanıklı. Temizlemesi kolay ve uzun ömürlüdür.

Hidrolik tahrikin benimsenmesi, Güçlü bir itme gücü sağlayabilir ve dolum hızını büyük ölçüde artırabilir. Çok miktarda sosis dolum işini kısa sürede tamamlayabilir, Büyük ölçekli üretimin ihtiyaçlarını karşılamak.

İyi bir sürekli çalışma kabiliyetine sahiptir ve sürekli olarak doldurma işi yapabilir.. Ayarlama veya bakım için sık sık durmanıza gerek yok. Uzun vadeli üretim görevleri için uygundur ve üretim verimliliğini artırır.

Sıkça Sorulan Sorular

Yüksek Verimlilik ve Kaliteli Seçim – Gondor Hidrolik Lavman Sosis Dolum Makinası

Gondor Hidrolik Sosis Doldurucu, sosis üretim hattınızda mükemmel son nokta olarak hizmet eder. Kıyma makinesi tarafından hazırlanan veya bir makine tarafından emülsifiye edilen dolguları alır. et kasesi kesici, Her sosisin dolgun ve tutarlı olmasını sağlayan hızlı ve hassas doldurma için hidrolik gücün kullanılması. Karışımların bir kaynaktan işlenip işlenmediği vakumlu et mikseriGelişmiş lezzet veya bağımsız çalışma için, yüksek verimli çıktıyı garanti eder. Gondor'u seçmek kusursuz bir seçim yapmak anlamına gelir, Ham malzemeleri zahmetsizce birinci sınıf sosis ürünlerine dönüştüren uçtan uca çözüm.