Gondor şişirilmiş yemek yapma makinesi Giriş

The şişirilmiş gıda ekstruder makinesi Çeşitli tahılların hammaddelerini mikserle homojen bir şekilde karıştırmak için gelişmiş çift vidalı vidalı ekstrüzyon teknolojisini benimser, ve daha sonra ekstruderde yüksek sıcaklık ve yüksek basınca maruz bırakılır. Kalıpları değiştirilerek çeşitli şekillerde şişirilmiş yiyecekler üretilebilir.

Şişirilmiş gıda makinesi çok çeşitli hammaddelerin özelliklerine sahiptir, rahat kullanım ve bakım, düşük enerji tüketimi ve yüksek çıktı. Şişirilmiş küçük yiyeceklerin gevrek bir tadı vardır, sindirimi kolay, benzersiz koku, taşıması kolay, ve tüketiciler için ideal bir atıştırmalık yiyecektir.

Gondor Gıda Şişirme Makinesi Modelleri

üzerinde tedarikçi olarak 20 Gıda makineleri imalatında uzun yıllara dayanan deneyim, Farklı ihtiyaçlarınızı karşılamak için çeşitli gıda ekstrüder modelleri sunuyoruz. Ücretsiz danışmanlık ve tatmin edici hizmet için bizimle iletişime geçin.

| Modeli |

Ana motor gücü |

Vida çapı |

Çıkış |

Boyut |

Ağırlık |

| GD-65 |

22kw |

F65 |

100-150 kg/saat |

2500*1000*1800mm |

1.2 T |

| GD-70 |

30kw |

Φ70 |

200-360 kg/saat |

4100*1000*1800mm |

1.8 T |

| GD-85 |

55kw |

Φ85 |

300-550 kg/saat |

4100*1000*1800mm |

2.5 T |

| GD-95 |

110kw |

F95 |

800-1200 kg/saat |

5800*1700*2000mm |

6 T |

Gondor Şişirilmiş Gıda Ekstruder Makinesi Uygulaması

Gıda ekstrüzyon makinesi, güçlü uyum yeteneği ile, çeşitli gıda ve ilgili işleme alanlarında derinden uygulanmıştır. Temel uygulama senaryoları temel olarak temel ürün fabrikalarını ve ilgili destekleyici endüstrileri içerir..

Temel Üretim Endüstrileri (Doğrudan İşleme)

Atıştırmalık Gıda İşleme TesisleriEvcil Hayvan Yemi FirmalarıYem Üretim TesisleriTahıl Derin İşleme EndüstrisiBesleyici Gıda Fabrikaları

Mısır çubukları gibi şişirilmiş atıştırmalıkların üretilmesi, patates cipsi, ve pirinç kekleri, çoklu tat adaptasyonunu destekleyen.

Evcil hayvan maması şekillendirme ve besin tutma gereksinimlerini karşılamak için yüksek proteinli şişirilmiş köpek ve kedi mamalarının işlenmesi.

Su ürünleri/kümes hayvanları için şişirilmiş yem üretimi, lezzeti ve sindirilebilirliği arttırmak.

Mısır ve pirinç gibi hammaddelerin şişirilmiş tahıl tozuna dönüştürülmesi, tahıl çubukları, ve diğer temel hammaddeler veya bitmiş ürünler.

Ek gıda üretmek, orta yaşlı ve yaşlı insanlar için besleyici pirinç sallamaları gibi şişirilmiş öğün yerine geçenler, rafine formül adaptasyonuna ulaşmak.

İlgili Destekleyici Endüstriler (Hammaddeler/İkincil İşleme)

Tarımsal Ürün İşleme Kooperatifleri/YetiştiricileriGıda Bileşeni TedarikçileriKüçük Yemek Atölyeleri

Satılmayan tahılları şişirilmiş yarı mamul ürünlere dönüştürme, Tarım ürünlerinin katma değerinin artırılması.

Kabarık tahıl kırıntıları üretmek, şişirilmiş protein tozu, ve alt gıda fabrikalarına tedarik sağlayacak diğer bileşenler.

Atıştırmalıkların ve yerel özel gıdaların farklı ihtiyaçlarını karşılamak için küçük partiler halinde özelleştirilmiş üretime uyum sağlama.

Gondor Şişirilmiş Gıda Ekstruder Makinesi Detayları

Gıda ekstruderlerimiz hijyen ve güvenliğe dayanmaktadır, son derece verimli ve pratiktir, sayısız öne çıkan özelliklerle övünen:

Paslanmaz çelik

Paslanmaz çelik tasarımı benimseyin, hijyenik standart, temiz, hijyenik, güvenli, uzun servis ömrü, ekipman yapısının kompakt tasarımı.

Güçlü Güç ve Sorunsuz Çalışma

Hız regülasyonu için frekans dönüştürücüyü benimseyin, güçlü güç, kararlı çalışma, elektrik tasarrufu.

Sıcaklık Kontrolü Daha Sezgisel ve Doğrudur

Görsel otomatik sıcaklık kontrol sistemi, sıcaklık kontrolü daha sezgisel ve doğrudur.

Sorunsuz Çalıştırın

Besleme sistemi tek ve çift vidalı beslemeyi benimser, Besleme düzgün ve stabildir. Besleme sistemi tek ve çift vidalı beslemeyi benimser, Besleme düzgün ve stabildir.

Öne Çıkan Bıçaklar

Döner kesici takım doğrusal yatak tasarımını benimser, ve ayarlama aracı doğru ve hızlıdır.

Gondor Şişirilmiş Gıda Ekstruder Makinesi Özellikleri

Şişirilmiş gıda ekstruder makineleri temel teknolojileri pratik tasarımla birleştiriyor, üstün performans ve güçlü uyarlanabilirlik sunar.

Frekans dönüştürücü hız regülasyonu için kullanılır, güçlü bir güçle, kararlı çalışma, tekdüze besleme ve maliyet tasarrufu.

Basınçlı yağlama sistemi, ekipmanın şanzıman kısmının daha uzun ömürlü olmasını sağlar.

Vida alaşımlı çelik nitrürleme ile işlenir, hangisi daha uzun servis ömrüne sahiptir, ve yapı taşı kombinasyon yapısı farklı ihtiyaçlara göre keyfi olarak birleştirilebilir.

Farklı vidalar ve uzunluk-çap oranları, farklı üretim süreçlerini karşılayabilir.

Görsel otomatik sıcaklık kontrol sistemi, sıcaklık kontrolü daha sezgisel ve doğrudur.

Vidanın kendi kendini temizleme işlevi vardır, temizlik için vidayı sökmeye gerek yoktur.

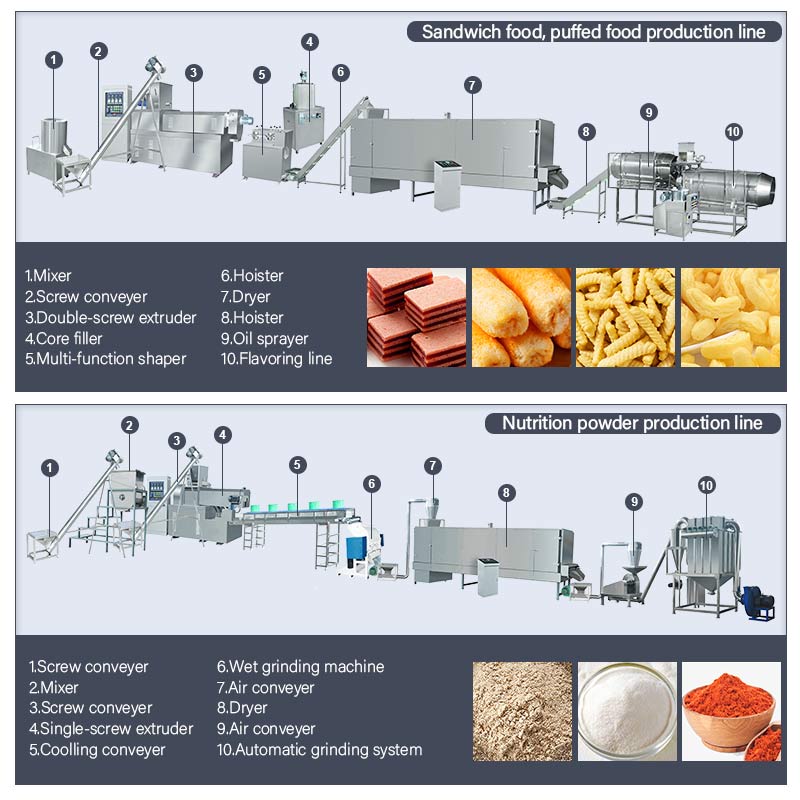

İlgili Ürün Tanıtımı

Daha verimli bir entegre şişirilmiş gıda üretim çözümü oluşturmak için, aşağıdaki ekipmanlar da kullanılabilir:

- Patlamış Mısır Makinesi: Mısır ham maddelerini profesyonelce şişirir, hızla çıtır ve tatlı patlamış mısır üretir.

- Fırın: Pişirme için hassas sıcaklık kontrolü, Şişirilmiş gıdaların gevrekliğini ve lezzet karmaşıklığını arttırmak.

- Yiyecek Mikseri: Tahıl ham maddelerini ve katkı maddelerini eşit şekilde karıştırır, şişirilmiş ürünlerde tutarlı tat sağlanması.

- Yıldız Anason Baharat Makinası: Verimli bir şekilde katlar ve mevsimler, çoklu lezzet ihtiyaçlarına uyum sağlamak ve şişirilmiş gıdaların lezzet profilini geliştirmek.

Ayrıca eksiksiz bir teklif sunuyoruz

mısır puf aperatif yiyecek üretim hattı. Bu destekleyici ekipmanlar yalnızca üretime yönelik yardımcı araçlar değildir., aynı zamanda üretim sürecinizi optimize etmek için pratik yardımcılar, Ürün yelpazenizi zenginleştirmek, ve kârlılığın artırılması. Detaylı parametreler ve teklifler için şimdi bize ulaşın, ve büyük ölçekli şişirilmiş gıda üretimi yükseltme yolculuğunuza başlayın!