Endüstriyel Buğday Freze Makinesi: Kapsamlı Bir Tahıl İşleme Çözümü

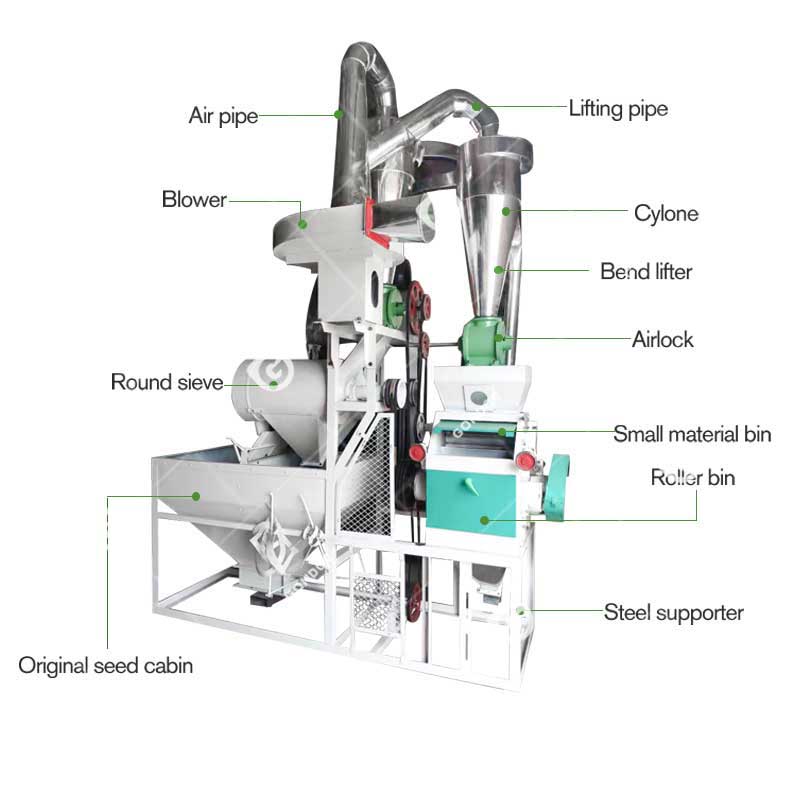

The endüstriyel buğday mısır unu freze makinesi hem buğday hem de mısır öğüten küçük ölçekli ev tipi un değirmenleri için uygun, çok yönlü bir tahıl işleme makinesidir, ve çeşitli tahılların ince işlenmesini gerektiren gıda fabrikaları için, kakao çekirdekleri dahil, soya fasulyesi, yulaf, ve farklı sertlikteki diğer malzemeler. Modüler bir tasarıma sahip, temel bileşenleri bir besleme sisteminden oluşur, taşlama sistemi, eleme sistemi, iletim sistemi, ve akıllı kontrol sistemi. Bu sistemler genel operasyonel verimliliği ve istikrarı sağlamak için uyum içinde çalışır. Daha da önemlisi, Kapalı yapısı toz sızıntısını etkili bir şekilde önler, Sadece sıkı hijyen standartlarını karşılamakla kalmıyor, aynı zamanda rutin bakım prosedürlerini basitleştirirken enerji tüketimini de önemli ölçüde azaltıyor.

Ultra ince un üretmek için hassas öğütme kapasitesi ile 40 ile 120 örgü, buğday öğütme makinesi un değirmenlerinde yaygın olarak kullanılmaktadır, gıda işleme tesisleri, pişirme malzemesi tedarikçileri, ve özel gıda üreticileri. İster geleneksel taş öğütülmüş un dokusunu takip eden zanaatkar erişte dükkanları, ister standart seri üretim gerektiren büyük ölçekli gıda fabrikaları olsun, ideal ürün kalitesine öğütme parametrelerinin ayarlanmasıyla ulaşılabilir. Bu uyarlanabilirlik, ekipmanın temel tahıl işlemeden yüksek katma değerli gıda üretimine kadar çeşitli ihtiyaçları karşılamasını sağlayarak ham maddelerden son ürünlere kadar hassas kontrol sağlar..

| Modeli | Çıkış (kg/saat) | Ağırlık (kilogram) | Boyut(mm) | Güç(kw) |

| 6F2235 | 200~350 | 800 | 2200*900*3150 | 7.5+3 |

| 6F2240 | 300~450 | 900 | 2250*1000*3150 | 11+3 |

| 6F2250 | 400~550 | 1000 | 2350*1000*3150 | 15+4 |

Un Değirmeni Makinası Talep Alanları

Un Üretim Firmaları

Bunlar ana talep tarafıdır, ekmek yapmak için çeşitli derecelerde un üretmek, erişte, kekler ve diğer yiyecekler.

Gıda İşleme Tesisleri

Erişte işleme tesisleri gibi, hamur tatlısı ambalajı üretim tesisleri, vesaire., ürünleri işlemek için belirli kalitede un gerektirir.

Fırıncılık Firmaları

Farklı un türlerine büyük talep var, Farklı tat ve özelliklere sahip fırınlanmış yiyeceklerin yapımında kullanılanlar.

Yem Endüstrisi

Tahılların ve diğer hammaddelerin farklı hayvanlara uygun yem tozuna dönüştürülmesi. Hayvanların sindirimini ve emilimini kolaylaştırmak için bazı yemlerin ince bir şekilde ezilmesi gerekir..

Likör Bira Fabrikası

Sorgum ve buğday gibi bazı hammaddelerin demleme işlemlerinden önce ezilmesi ve fermente edilmesi gerekir..

Kimya Endüstrisi

Hammaddelerin veya kimyasal ürünler için katkı maddelerinin üretimi amacıyla belirli hammaddeleri kırmak için un değirmenlerini kullanın.

İlaç Endüstrisi

İlaçların üretim sürecinde farklı dozaj formları için hammadde parçacık boyutu gereksinimlerini karşılamak amacıyla bazı tıbbi malzemelerin ezilmesi.

Bilimsel Araştırma Alanı

Tarımsal araştırma kurumları: Tahıl bitkilerinin bileşimini ve yapısını incelemek için kullanılır, analiz ve test için tahılın toz haline getirilmesini gerektiren.

Gıda Araştırma Birimleri

Yeni gıda formülleri geliştirme sürecinde, test için hammaddelerin öğütülmesi gerekir.

Bazı Büyük Ölçekli Kapsamlı İşleme Üsleri

Çeşitli mahsullerin işlenmesi, un değirmeni işleme ekipmanlarından biridir.

Gondor Buğday Öğütme Makinesinin Mükemmel Avantajları

-

Yüksek Üretim Kapasitesi

Büyük ölçekli üretimin ihtiyaçlarını karşılamak için birim zamanda büyük miktarda tahıl hammaddesini işleyebilir.

-

Sürekli Çalışma

Uzun süre stabil çalışma özelliğine sahiptir., sık sık kapanmadan ve dinlenmeden, üretim verimliliğini büyük ölçüde artıran.

-

Yüksek Derecede Otomasyon

Manuel müdahaleyi azaltın, besleme gibi bir dizi işlemi otomatik olarak tamamlar, bileme, tarama ve boşaltma, zamandan ve iş gücünden tasarruf.

-

Hassas Taşlama

Öğütme inceliği ihtiyaca göre ayarlanabilir, ve her ürün grubunun tutarlılığı garanti edilebilir.

-

Kolay Kurulum

Tüm arayüzler flanşlarla bağlanmıştır, az yer kaplayan ve basit operasyonla.

-

Makul Yapı

Kararlı çalışma, güvenilir performans, düşük gürültü, toz yok, güvenli ve hijyenik, enerji tasarrufu ve çevre dostu.

Temel Teknik Özellikler

Bakım ve Optimizasyon Önerileri

Her vardiyadan sonra taşlama disklerindeki artık malzemeleri temizleyin. Elek ağı aşınmasını haftalık olarak inceleyin.

İsteğe bağlı IoT modülü, ekipman performans verilerinin gerçek zamanlı izlenmesine ve uzaktan arıza teşhisine olanak tanır.

Her vardiyadan sonra taşlama disklerindeki artık malzemeleri temizleyin. Elek ağı aşınmasını haftalık olarak inceleyin.

Gondor Buğday Mısır Unu Öğütme Makinesi – Verimlilikte Yeni Bir Çağ Açıyoruz

Buğday mısır unu öğütme makinemiz, un üretim verimliliğini artırmak için en iyi seçimdir! Güçlü bir öğütme kapasitesine sahiptir ve büyük miktarlardaki tahılları hızlı bir şekilde işleyebilir., zamandan ve maliyetten tasarruf etmenizi sağlar. Ek olarak, Bu ekipman tarafından üretilen nihai ürünler ince un özelliklerine sahiptir, yüksek gluten içeriği, az miktarda yabancı madde, ve besin değeri yüksek. Gondor'u seçmek verimliliği seçmek anlamına gelir, kalite ve güven. Şimdi sipariş ver, birlikte daha iyi bir gelecek yaratalım!