Präzise Salzlakeinjektion für verbesserte Fleischqualität

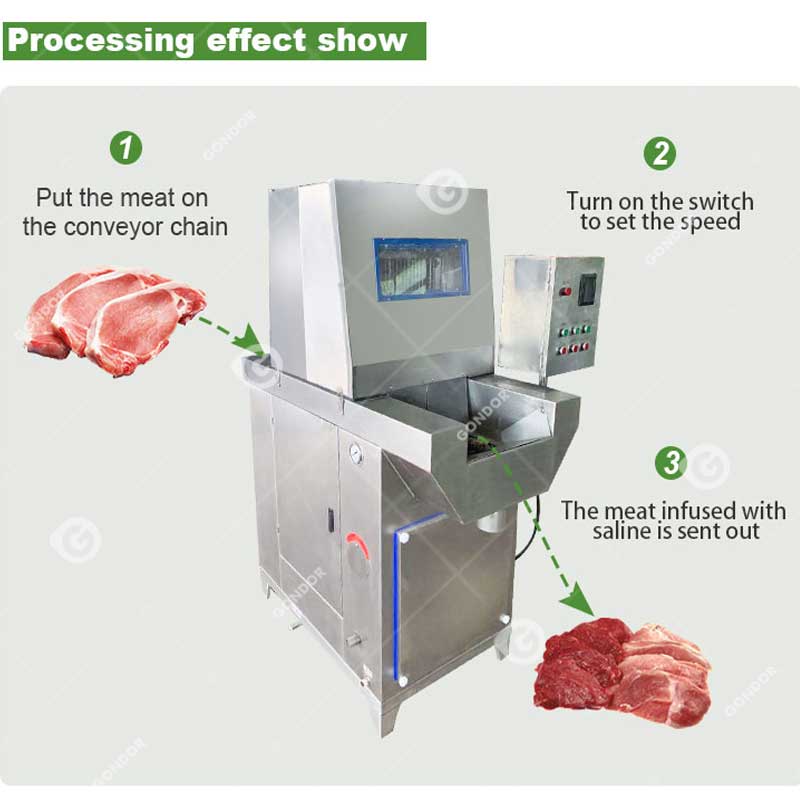

Der Salzlake-Injektormaschine für Fleisch ist ein unverzichtbarer Ausrüstungsgegenstand in modernen Fleischverarbeitungsbetrieben, spielen eine entscheidende Rolle bei der Verbesserung der Produktqualität und Produktionseffizienz. Seine Hauptfunktion besteht darin, vorbereitete Salzlösungen gleichmäßig einzuspritzen, Beizmittel, oder Gewürzflüssigkeiten tief in das Fleischgewebe eindringen. Unter Verwendung einer Reihe feiner Nadeln, die unter kontrolliertem Druck arbeiten, Die Maschine verteilt die Flüssigkeit schnell in den Fleischfasern. Was mehr ist, Dieses Verfahren erhöht nicht nur die Zartheit und Saftigkeit des Fleisches, sondern beschleunigt auch den Beizvorgang im Vergleich zu herkömmlichen Eintauchmethoden erheblich, Dies ermöglicht schnellere Produktionszyklen und eine gleichmäßige Aromadurchdringung.

| Modell | Leistung | Kapazität | Injektion | Stromspannung | Einspritzgeschwindigkeit | Maschinengröße |

| Zyz-4 | 4.1kw | 300kg | 0.45-0.9Mpa | 380v | 40-70m/mein | 1350x750x1650mm |

| Zyz-8 | 5.1kw | 700kg | 0.45-0.9Mpa | 380v | 40-70m/mein | 1550x880x1650mm |

| Zyz-1 | 6.2kw | 900kg | 0.45-0.9Mpa | 380v | 40-70m/mein | 1850x1350x1800mm |

Anwendbare Branchen der Gondor-Fleischinjektormaschine

- Zum Beispiel Schinken, Wurst, usw., durch Soleinjektion, das Fleisch ist zarter und saftiger, und der Beizvorgang wird beschleunigt.Hersteller von Fleischprodukten

- Verarbeiten Sie das geschnittene Fleisch vor, um es für die weitere Verarbeitung vorzubereiten.Große Schlachthöfe

- Produzieren Sie Produkte wie zubereitetes Hühnchen und zubereitetes Rindfleisch, Einspritzen von Salzlake zur Verbesserung von Geschmack und Aroma.Produktionsanlagen für zubereitete Lebensmittel

- Bereitstellung standardisierter halbfertiger Lebensmittelzutaten für Ketten-Catering-Unternehmen, und die Einspritzung von Salzlake kann eine gleichbleibende Lebensmittelqualität gewährleisten.Zentrale Küche

- Zentrale Küche, Bereitstellung von mit Salzinjektion behandelten Fleischzutaten für seine Geschäfte, Erleichterung des Kochens und Zubereitens von Gerichten im Laden.Catering-Dienstleistungsbranche

- Erfüllen Sie die Anforderungen ausländischer Märkte an Produktqualität und Geschmack, und Soleinjektion kann die Wettbewerbsfähigkeit der Produkte verbessern.Export-Lebensmittelunternehmen

- Wird für experimentelle Forschungs- und Lehrdemonstrationen verwendet, um die Auswirkungen der Salzlakeinjektion auf die Fleischqualität zu untersuchen und die Verarbeitungstechnologie zu optimieren.Lehrgebiete

Einzigartige Leistungsmerkmale der Gondor-Kochsalzinjektionsmaschine

Einfache Bedienung, hoher Automatisierungsgrad, reduzierter manueller Eingriff, reduzierte Arbeitsintensität, und auch die Standardisierung der Produktion verbessert.

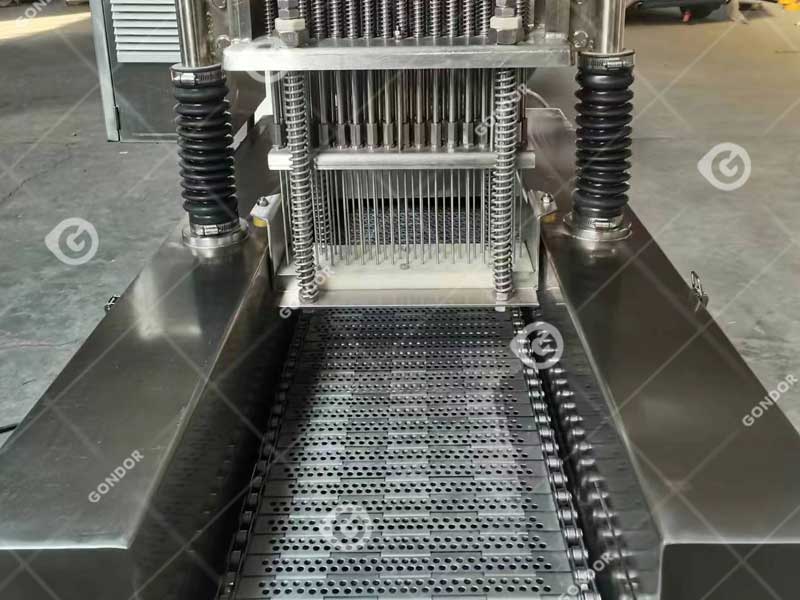

Die vierstufige Filterfunktion kann die Partikel in der Flüssigkeit rechtzeitig herausfiltern, Dadurch wird effektiv sichergestellt, dass das Injektionsnadelloch nicht blockiert wird.

Verwendung einer SPS-Steuerung, Der Kettenschritt und die Schrittgeschwindigkeit können synchron zur Nadelgeschwindigkeit angepasst werden.

Es kann das Einspritzvolumen und die Einspritztiefe der Salzlake genau steuern, um sicherzustellen, dass jedes Stück Fleisch die Salzlake gleichmäßig aufnehmen und den besten Beizeffekt erzielen kann.

Die mit Lebensmitteln in Berührung kommenden Teile bestehen aus Edelstahl und anderen Materialien, die den Lebensmittelhygienestandards entsprechen, die korrosionsbeständig sind, leicht zu reinigen, und verursacht keine Verschmutzung des Fleisches.

Die Injektionsnadel besteht aus einer einzelnen Nadel und einem einzelnen Schlauch, und die Injektion ist gleichmäßig. Das unabhängige Federdesign kann beim Auftreffen auf harte Gegenstände automatisch zurückprallen.

Es eignet sich nicht nur für gewöhnliches Fleisch wie Schweinefleisch, Rindfleisch, und Hammelfleisch, Kann aber auch zur Salzinjektion verschiedener Geflügel- und Wasserprodukte verwendet werden, um den unterschiedlichen Verarbeitungsanforderungen gerecht zu werden.

Upstream- und Downstream-bezogene Ausrüstung

Die Salzlake-Injektormaschine kann effizient mit den folgenden Geräten zusammenarbeiten, um eine Produktionslinie für die Fleischverarbeitung zu bilden:

Vorverarbeitungsausrüstung:

- Gefrorener Fleischwolf: Fördert das injizierte Fleisch direkt zum Fleischwolf, Erzielung eines kontinuierlichen Marinier- und Zerkleinerungsvorgangs.

- Vakuum-Fleischbecher: Nach der Injektion, Der Taumelvorgang sorgt für eine gleichmäßige Durchdringung der Sole, Verbesserung der Fleischzartheit und Geschmacksintegration.

Downstream-Verarbeitungsausrüstung:

- Fleischmixer: Geeignet für Produkte wie Würstchen und Fleischbällchen, Es vermischt das injizierte Fleisch mit Hilfsstoffen, um eine gleichmäßige Würze zu gewährleisten.

- Räucherofen/Kochlinie: Marinierte Fleischprodukte können direkt in den Garprozess gelangen, Bildung eines nahtlosen automatisierten Prozesses.

Häufig gestellte Fragen

Salzlake-Injektormaschine für Fleisch – Hersteller der Gondor-Gruppe

Entscheiden Sie sich für die Salzlake-Injektormaschine für Fleisch von Gondor, um die Qualität Ihrer Fleischverarbeitung zu verbessern! Unsere Fleischinjektormaschine ist präzise und effizient, Dadurch erhält jedes Stück Fleisch einen gleichmäßigen Geschmack. Außerdem, seine einfache Bedienung, stabile leistung, und ein hochwertiger Kundendienst kann Ihnen Sicherheit geben. Kaufen Sie jetzt, um Ihre Produkte wettbewerbsfähiger zu machen! Schließen Sie sich Gondor an, um eine köstliche Zukunft zu schaffen!