A medida que crece la demanda del mercado global, La tecnología de producción de chocolate es cada vez más refinada.. Especialmente en la fusión y procesamiento del chocolate., Se están aplicando equipos cada vez más avanzados a la línea de producción para mejorar la eficiencia de la producción y la calidad del chocolate.. entre ellos, el maquina para derretir chocolate y la máquina de cacao se han convertido en el foco de la industria.

Máquina para derretir chocolate: Garantiza un control preciso de la temperatura

La fusión del chocolate es un paso clave en el proceso de producción.. Elegir una máquina para fundir chocolate con control de temperatura eficiente y precisa es fundamental para garantizar la calidad del producto.. Las modernas máquinas para derretir chocolate utilizan tecnología avanzada para garantizar una fusión uniforme del chocolate y un control preciso de la temperatura, al tiempo que mejoran la eficiencia de producción y el ahorro de energía.. Estas son las principales características de las máquinas para fundir chocolate.:

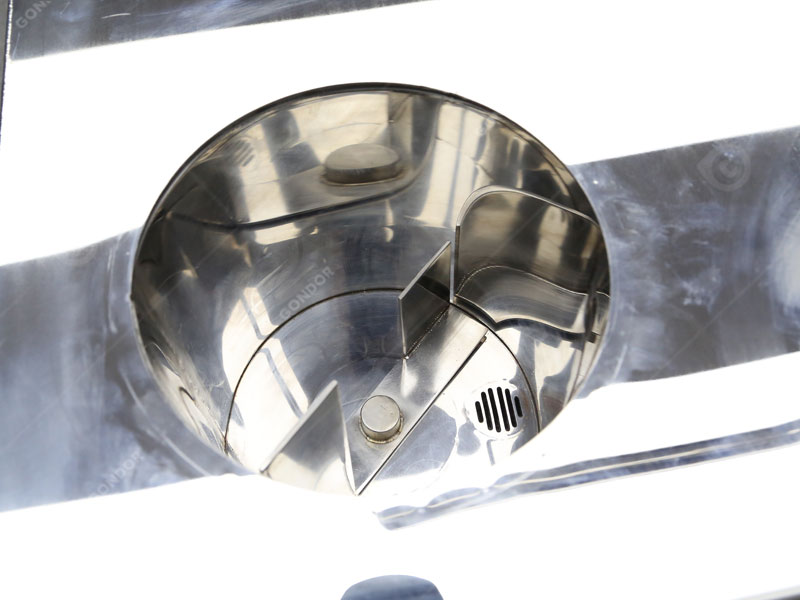

Tanque para derretir chocolate: Calefacción uniforme

Los tanques para derretir chocolate se utilizan principalmente para almacenar y calentar chocolate líquido para garantizar temperaturas estables durante el almacenamiento y el procesamiento.. Los tanques de fusión de alta gama suelen estar equipados con un sistema de aislamiento de doble capa para evitar fluctuaciones de temperatura que provocan la cristalización y reducir la pérdida de calor y el consumo de energía.. Al mismo tiempo, Los modernos tanques de fusión también están equipados con un sistema de agitación para garantizar la uniformidad y fluidez del chocolate para su posterior procesamiento.. Elegir el tanque de fusión adecuado puede ayudar a mejorar la consistencia del producto, reducir las tasas de desperdicio, y así mejorar la eficiencia de la producción y los beneficios económicos..

Máquina de cacao: El vínculo principal entre los frijoles crudos y el chocolate

Los granos de cacao son la materia prima básica del chocolate., y la máquina de cacao juega un papel vital en la producción de chocolate. A medida que aumenta la demanda de chocolate de alta calidad, Los fabricantes de chocolate dependen cada vez más de equipos avanzados de procesamiento de cacao para garantizar una conversión eficiente de granos crudos a licor de cacao.. Este equipo no sólo mejora la eficiencia de la producción sino que también ayuda a conservar el sabor y los nutrientes naturales de los granos de cacao.. Las siguientes son las principales funciones y características de los equipos de procesamiento de cacao.:

Una tecnología innovadora promueve el desarrollo de equipos para chocolate

Con el avance tecnológico, La industria de equipos para chocolate continúa innovando.. Las modernas máquinas para fundir chocolate y los tanques para fundir chocolate han introducido el Internet de las cosas (IoT) tecnología, Permitir a los fabricantes monitorear remotamente el estado y la temperatura del equipo y mejorar la precisión de la gestión.. Al mismo tiempo, inteligencia artificial (AI) La tecnología permite que el equipo ajuste automáticamente los parámetros., Mejorar la flexibilidad y la inteligencia de la producción.. La nueva generación de equipos también adopta tecnologías respetuosas con el medio ambiente y de ahorro de energía para reducir los costes de producción y el impacto medioambiental., Proporcionar a los fabricantes de chocolate importantes ventajas competitivas en el mercado..

Optimización de la colaboración de equipos: Mejora de la eficiencia de las líneas de producción de chocolate

Las líneas de producción de chocolate no sólo dependen de máquinas para fundir chocolate, bronceado fundidor de chocolate,k, y equipos de procesamiento de cacao, pero también requieren la coordinación de otros equipos clave. molinos de bolas para chocolate, maquinas para hacer chocolate, refrigeradores, y otros equipos garantizan una mezcla uniforme de las materias primas, relleno preciso de chocolate, y alta calidad en todos los eslabones de producción. La colaboración eficiente de este equipo mejora la eficiencia de la producción., calidad del producto, y consistencia. Impulsado por la creciente demanda mundial de chocolate de alta calidad, Los fabricantes deben invertir en equipos avanzados para seguir siendo competitivos y lograr una producción inteligente..