As the global market demand grows, chocolate production technology is becoming increasingly refined. Especially in the melting and processing of chocolate, more and more advanced equipment is being applied to the production line to improve production efficiency and chocolate quality. Among them, the chocolate melting machine and the cacao machine have become the industry’s focus.

Chocolate Melting Machine: Ensures Precise Temperature Control

Chocolate melting is a key step in the production process. Choosing an efficient and precise temperature-controlled chocolate melting machine is essential to ensure product quality. Modern chocolate melting machines use advanced technology to ensure uniform melting of chocolate and precise temperature control while improving production efficiency and energy saving. Here are the main features of chocolate melting machines:

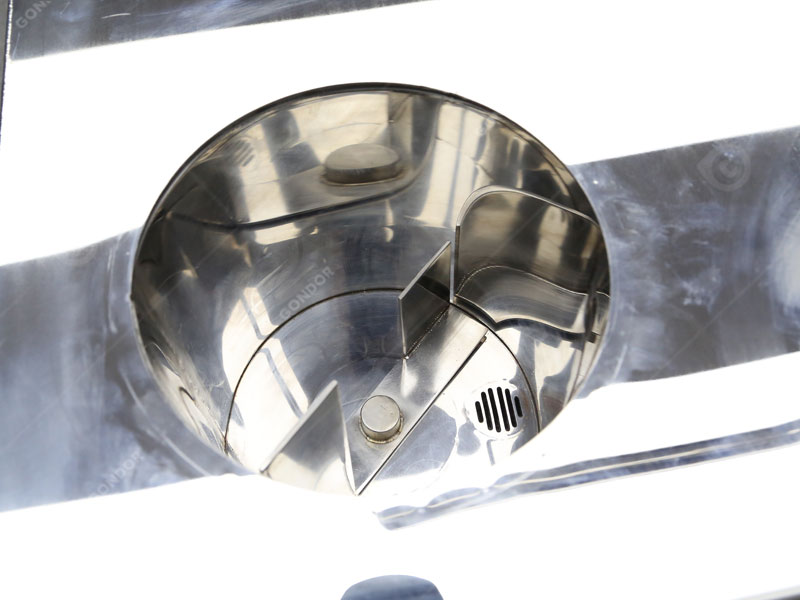

Chocolate Melter Tank: Uniform Heating

Chocolate melting tanks are mainly used to store and heat liquid chocolate to ensure stable temperatures during storage and processing. High-end melting tanks are usually equipped with a double-layer insulation system to avoid temperature fluctuations that lead to crystallization and reduce heat loss and energy consumption. At the same time, modern melting tanks are also equipped with a stirring system to ensure the uniformity and fluidity of chocolate for subsequent processing. Choosing the right melting tank can help improve product consistency, reduce scrap rates, and thus improve production efficiency and economic benefits.

Cocoa Machine: The Core Link from Raw Beans to Chocolate

Cocoa beans are the basic raw material of chocolate, and the cacao machine plays a vital role in chocolate production. As the demand for high-quality chocolate increases, chocolate manufacturers are increasingly relying on advanced cocoa processing equipment to ensure efficient conversion from raw beans to cocoa liquor. This equipment not only improves production efficiency but also helps retain the natural flavor and nutrients of cocoa beans. The following are the main functions and features of cocoa processing equipment:

Innovative Technology Promotes the Development of Chocolate Equipment

With technological advancement, the chocolate equipment industry continues to innovate. Modern chocolate melting machines and melting tanks have introduced Internet of Things (IoT) technology, allowing manufacturers to remotely monitor equipment status and temperature and improve management accuracy. At the same time, artificial intelligence (AI) technology enables equipment to automatically adjust parameters, improving production flexibility and intelligence. The new generation of equipment also adopts environmentally friendly and energy-saving technologies to reduce production costs and environmental impact, providing chocolate manufacturers with significant market competitive advantages.

Equipment Collaboration Optimization: Improving the Efficiency of Chocolate Production Lines

Chocolate production lines not only rely on chocolate melting machines, chocolate melter tan,k, and cocoa processing equipment but also require the coordination of other key equipment. Chocolate ball mills, chocolate panning machines, coolers, and other equipment ensure uniform mixing of raw materials, precise filling of chocolate, and high quality in all production links. The efficient collaboration of this equipment improves production efficiency, product quality, and consistency. Driven by the increasing global demand for high-quality chocolate, manufacturers must invest in advanced equipment to remain competitive and achieve intelligent production.