Como uno de los postres favoritos de los consumidores de todo el mundo., La tecnología de producción de chocolate mejora constantemente.. Desde la producción a gran escala en fábricas hasta pequeños talleres artesanales de chocolate, Nuevos equipos y procesos están impulsando la innovación y el desarrollo en la industria.. En este artículo, Nos centraremos en tres equipos clave.: dispensador de chocolate liquido, depositador de chocolate manual, y batidora de chocolate industrial, y explorar cómo potencian la producción de chocolate.

Dispensador de chocolate líquido: La combinación perfecta de precisión y eficiencia

Un dispensador de chocolate líquido es un tipo de equipo diseñado para la producción y procesamiento de chocolate.. Su función principal es distribuir el chocolate líquido derretido en moldes o aplicarlo sobre otras superficies de alimentos de manera precisa..

Escenarios de aplicación

Principales ventajas

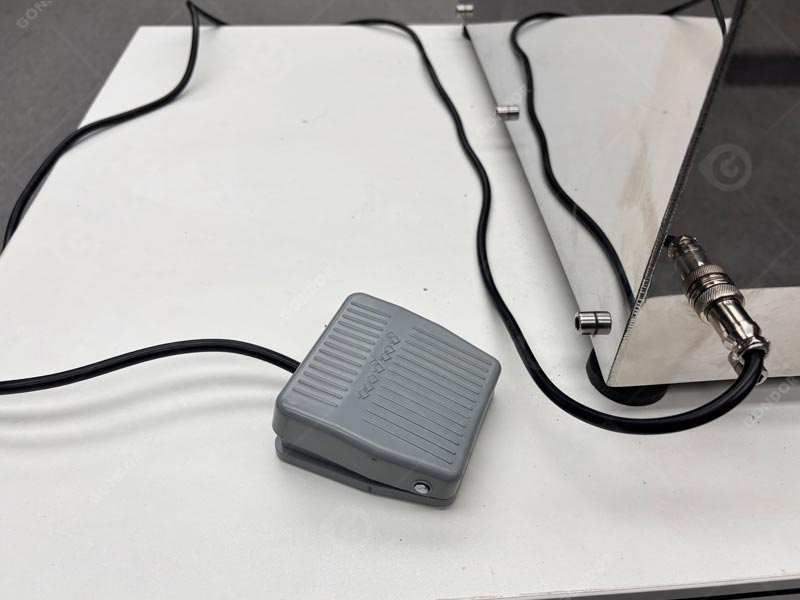

Depositadora de chocolate manual: Una herramienta flexible y de última generación

Comparado con equipos automatizados, Los depositadores de chocolate manuales ofrecen una mayor flexibilidad para artesanos y pequeñas empresas.. Permite a los operadores ajustar de manera flexible la cantidad de chocolate depositado según la demanda., que es muy adecuado para lotes pequeños y necesidades de producción diversificadas.

Características

Escenarios de uso

- Producción personalizada: Satisfacer necesidades personalizadas, como bodas, cajas de regalo de chocolate navideñas, etc..

- Propósito de la capacitación: Muy adecuado para que los principiantes aprendan a elaborar productos de chocolate de alta calidad..

Mezclador de chocolate industrial: La base de la alta calidad

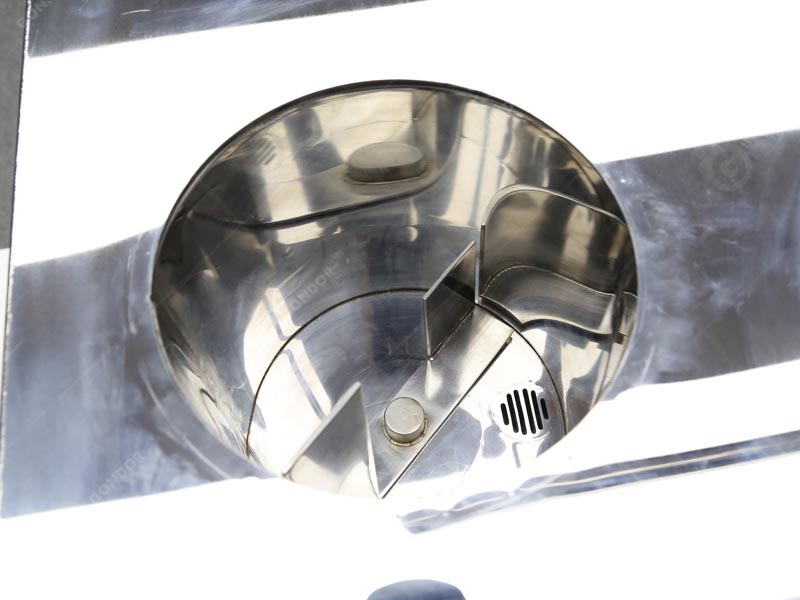

La mezcladora de chocolate industrial es uno de los equipos clave en la producción de chocolate.. Se encarga de mezclar las materias primas. (como licor de cacao, azúcar, productos lácteos, etc.) igualmente, Sentar las bases para el posterior refinado y moldeado..

Funciones principales

Aspectos técnicos destacados

- Equipado con un sistema de control de temperatura para garantizar que la temperatura sea moderada durante el proceso de mezcla y no afecte la calidad del chocolate..

- Diseño de paleta mezcladora de alta velocidad para acortar el tiempo de mezcla.

Tanque de mezcla de chocolate

Colaboración: Integración de equipos para la optimización de la producción

En la producción moderna de chocolate, Estos tres tipos de equipos tienen cada uno sus funciones y juntos forman una cadena de producción eficiente.. Por ejemplo, después de que la mezcladora de chocolate industrial mezcle las materias primas, se puede transferir directamente al dispensador de chocolate líquido para completar el moldeo por inyección; y para necesidades personalizadas, La máquina de moldeo por inyección de chocolate manual ofrece posibilidades de operación flexibles..

Recomendación de equipo de extensión

Además del equipo anterior, otros equipos como maquinas depositadoras de chocolate, túneles de enfriamiento, y maquinas para hacer chocolate También juegan un papel indispensable en la producción de chocolate.. Integrando múltiples equipos, Las empresas pueden lograr una mayor eficiencia de producción y calidad del producto..

Contáctenos para más soluciones de producción de chocolate.! Brindamos a los clientes servicios integrales desde la selección de equipos hasta la instalación., ayudando a que su negocio de chocolate tenga éxito!