Recubrimiento eficiente para la producción de alimentos de calidad

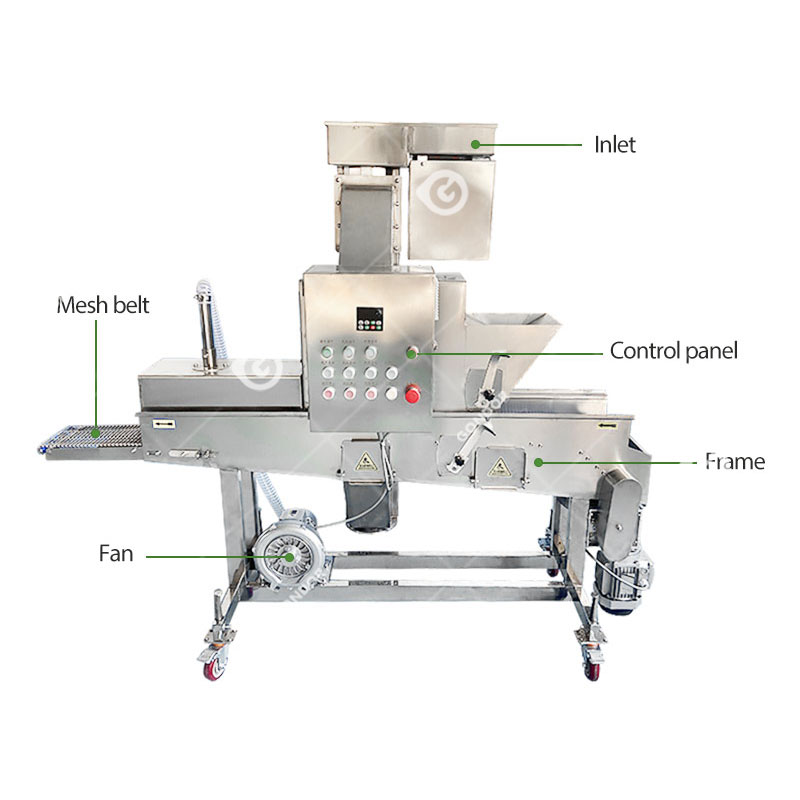

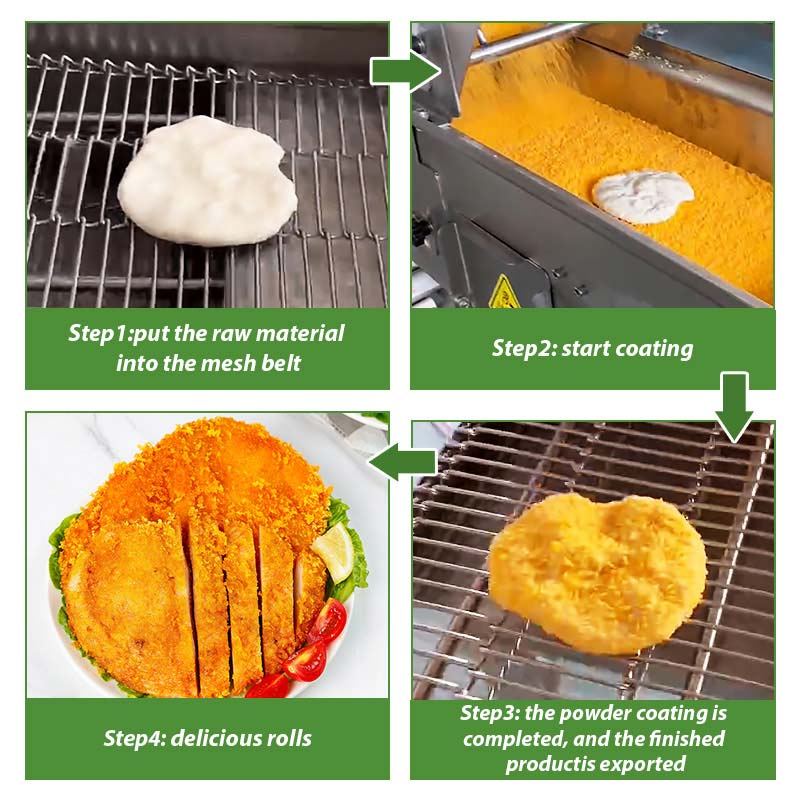

El Gondor empanadora automática de pollo es un dispositivo especialmente diseñado para aplicar una capa consistente y uniforme de salvado o pan rallado sobre diversos productos alimenticios.. Su construcción robusta generalmente incluye un puerto de alimentación receptor., un sistema transportador sincronizado, un mecanismo de distribución de salvado de alta eficiencia, y una salida de descarga regulada. En funcionamiento, Los alimentos se introducen en el punto de alimentación y el transportador los transporta de manera constante.. El diseño innovador garantiza que las migas se suministren continuamente desde la tolva superior y se coloquen estratégicamente a lo largo de la cinta de malla., envolviendo el producto desde múltiples ángulos para una completa, 360-cobertura de grado.

| Modelo | GD-200 | GD-400 | GD-600 |

| Ancho del cinturón | 200milímetros | 400milímetros | 600milímetros |

| Fuerza | 0.86kilovatios | 3.7kilovatios | 3.7kilovatios |

| Tamaño | 1720*650*1400milímetros | 2638*1050*2280milímetros | 2638*1050*2280milímetros |

| Peso | 230kilos | 450kilos | 620kilos |

Industrias relacionadas con el uso de la máquina empanadora automática Gondor

Beneficios considerables de la máquina empanadora de pollo Gondor

Mejorar la calidad del producto

Asegúrese de que el pan rallado esté adherido uniformemente., para que el producto terminado tenga una apariencia consistente y mejor sabor, mejorando así la competitividad en el mercado del producto..

Aumentar la diversidad de productos

El espesor del recubrimiento y la fórmula se pueden ajustar según las diferentes necesidades., y se pueden producir productos de diversos sabores y estilos para satisfacer una gama más amplia de necesidades del mercado..

Ahorro de energía y protección del medio ambiente

El modo de funcionamiento eficiente ahorra energía relativamente, cumple con los requisitos del desarrollo sostenible, y reduce los costos operativos a largo plazo.

Mejorar la eficiencia de la producción

Puede cubrir rápida y uniformemente los alimentos con pan rallado., acortar enormemente el tiempo de procesamiento, y aumentar la producción por unidad de tiempo.

Ahorre Materias Primas

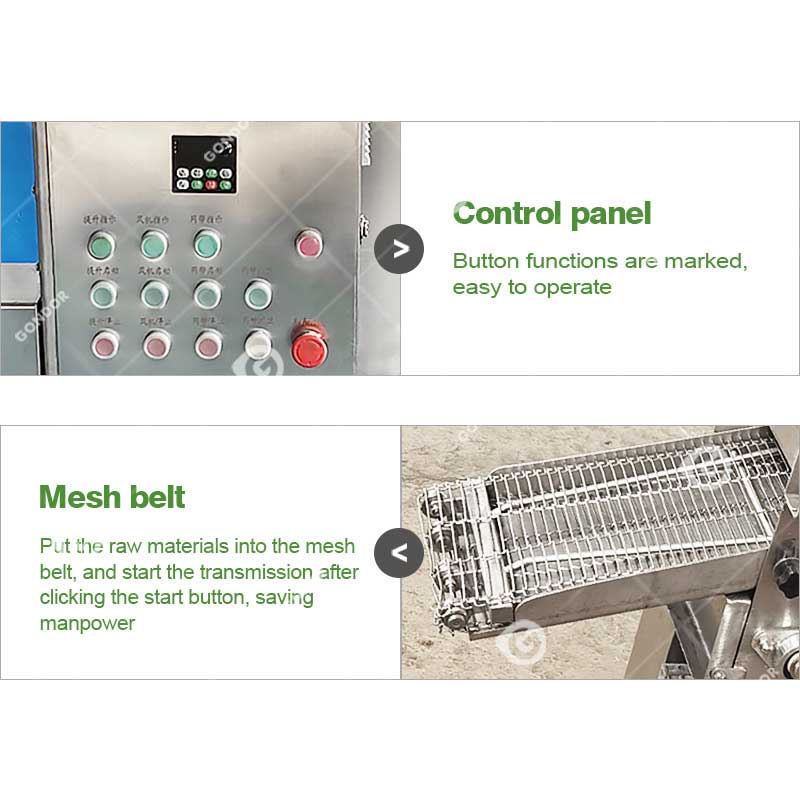

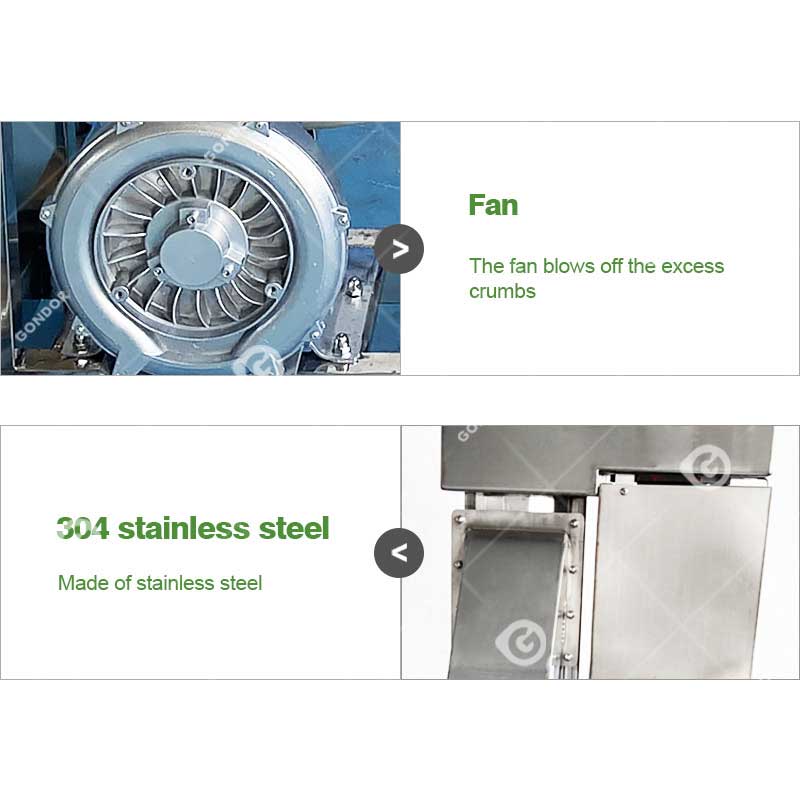

Ajustar la cantidad de pan rallado, y luego eliminar el exceso de migas mediante un fuerte sistema de viento.

Seguro y duradero

Hecho de acero inoxidable, estructura razonable, larga vida útil. Buen rendimiento de protección de seguridad y funcionamiento sencillo..

Construcción de una línea completa de producción de recubrimiento y fritura

La máquina recubridora de pan rallado es un componente fundamental en las líneas de procesamiento de alimentos., con su máxima eficiencia obtenida a través de una integración perfecta con equipos ascendentes y descendentes. A través del diseño científico., Se puede establecer un sistema de producción continua altamente automatizado..

Integración de equipos de preprocesamiento:

- Máquina automática para formar hamburguesas: Procesa carne cruda en formas estandarizadas (p.ej., empanadas redondas) y los alimenta directamente a la máquina de recubrimiento a través de cintas transportadoras, asegurando dimensiones uniformes para un recubrimiento consistente.

- Recubrimiento de masa: Antes de empanizar, cubre uniformemente las superficies de los alimentos con una masa líquida (mezcla de harina o huevo batido) como adhesivo para garantizar una adhesión segura del empanado.

Integración de equipos de posprocesamiento:

- Freidora Continua: Los alimentos rebozados entran directamente a la línea de fritura., se somete a modelado y cocción a temperaturas y tiempos preestablecidos para formar una masa dorada., corteza crujiente.

- Línea de horneado con aire caliente (Alternativa saludable): Para productos bajos en grasa, Conéctese a un equipo para hornear que utilice aire caliente en lugar de aceite para cocinar de forma más saludable..

- Congelador de túnel IQF: Al producir comidas preparadas congeladas, Los productos fritos/horneados ingresan inmediatamente al túnel de congelación rápida para retener jugos y sabor..

Máquina empanadora automática de pollo Gondor – Imprescindible para actualizaciones deliciosas

Si todavía estás buscando una empanadora de pollo automática, Gondor Machinery es su mejor opción para mejorar la calidad del producto! Nuestra empanadora automática es fácil de operar y tiene un recubrimiento uniforme., que puede agregar un atractivo atractivo a su comida. Un control preciso ahorra materias primas, y el funcionamiento eficiente aumenta la producción. Además, Ofrecemos servicio postventa de alta calidad., para que no tengas que preocuparte por eso. Elegir Gondor es elegir eficiencia y calidad. Ven, cómpralo y comienza un nuevo viaje de delicias.!