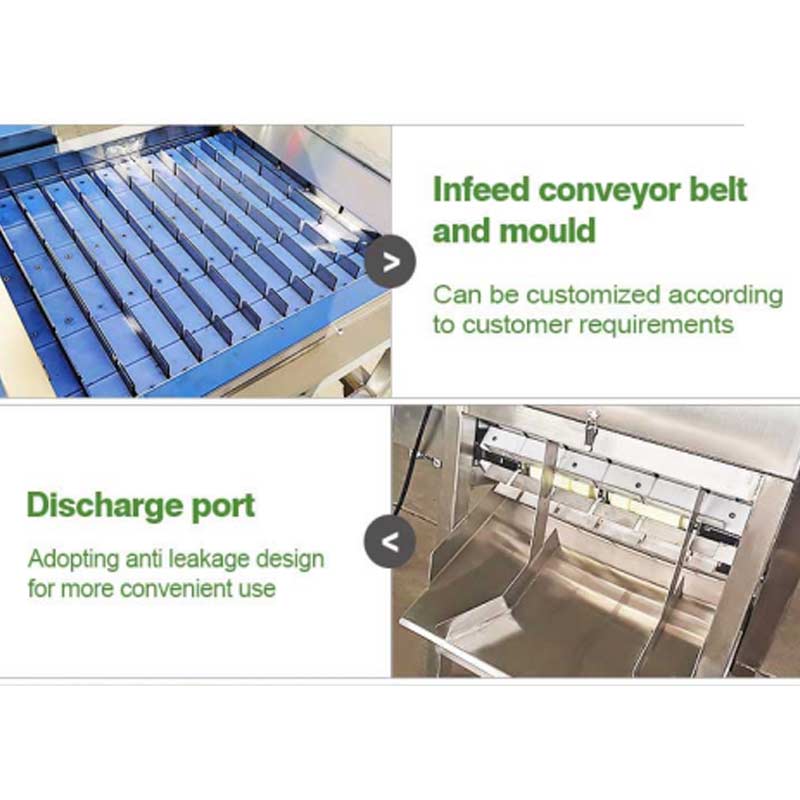

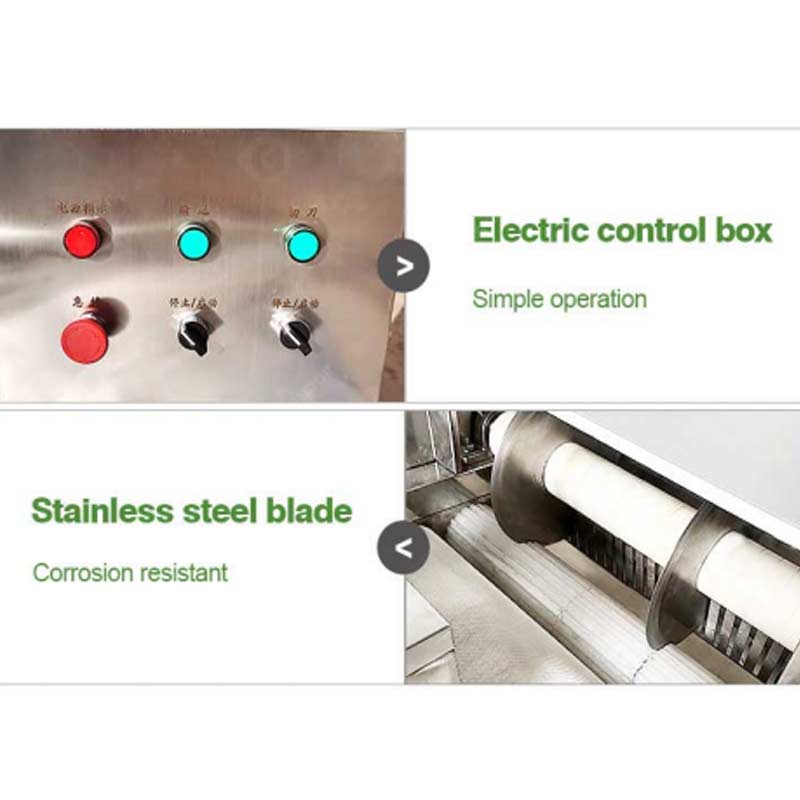

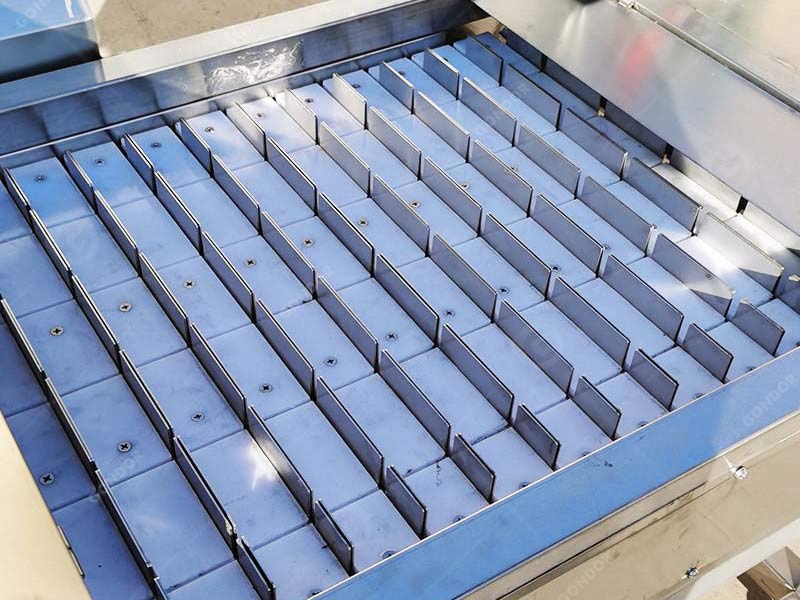

Toda la máquina del máquina cortadora de cabeza de pescado está hecho de acero inoxidable apto para uso alimentario, que ofrece las ventajas de resistencia al óxido y a la corrosión.. Además, el cortador está hecho de acero especial al manganeso (acero inoxidable 402), que no sólo es adecuado para cortar pescado con cola de pelo y con cuchillo, sino que también garantiza una larga vida útil. El equipo presenta un diseño compacto., una hermosa apariencia, fácil operación, bajo consumo de energía, y un excelente efecto de corte de huesos. Además, La longitud de los segmentos de la cola del cabello se puede personalizar según las necesidades del usuario., lo que le permite cumplir con requisitos de procesamiento diversificados. Su función de corte automático es altamente eficiente., con cortes prolijos y sin escombros, mientras que las diferentes partes se separan a través de diferentes puertos de descarga para facilitar el procesamiento. El equipo también admite regulación de velocidad de frecuencia variable., es simple de operar, y solo requiere dos personas. Como resultado, Es ampliamente utilizado en plantas procesadoras de alimentos., plantas de procesamiento de productos acuáticos, y otras unidades similares.

| Modelo | GD-1 | GD-2 |

| Capacidad | 1000kg/hora | 200kg/hora |

| Tamaño | 1360*1170*1060milímetros | 1100*500*850milímetros |

| Peso | 165kilos | 700kilos |

La máquina cortadora de cabezas de pescado sirve principalmente a campos industriales

Las máquinas cortadoras de pescado se utilizan ampliamente en muchas industrias.. Debido a sus funciones de corte eficientes y precisas, Pueden satisfacer las necesidades de procesamiento de diferentes tipos de pescado y otros materiales en tiras., mejorar significativamente la eficiencia de la producción y reducir los costos laborales. Las siguientes son las áreas industriales a las que sirve principalmente.:

Excelente ventaja de eficiencia del cortador de cabeza de pescado Gondor

Este equipo cuenta con una función de corte totalmente automática., Reducir significativamente el trabajo manual y mejorar la eficiencia de la producción..

Los gajos de pescado cortados quedan limpios y uniformes., sin residuos de escombros, Garantizar que la calidad del producto cumpla con altos estándares..

Diferentes partes (cabeza de pez, cuerpo de pez, cola de pez) están separados a través de diferentes puertos de descarga, lo cual es conveniente para el procesamiento posterior y ahorra tiempo.

No sólo apto para peces de cola de pelo y de cuchillo., pero también puede cortar algas, carne seca y otros ingredientes para mejorar la utilización del equipo.

Con soporte para regulación de velocidad de frecuencia variable., La velocidad de corte se puede ajustar de forma flexible para adaptarse a los diferentes requisitos de producción..

El equipo es simple y fácil de operar., y solo se necesitan dos personas para completar la operación de manera eficiente, reduciendo los costos laborales.

Las longitudes de los segmentos de pescado se pueden personalizar según las preferencias del usuario., Atendiendo a diversas necesidades de procesamiento y minimizando la necesidad de ajustes frecuentes..

Este equipo es ampliamente aplicable en diversas industrias de procesamiento., permitiendo a las empresas manejar eficientemente grandes pedidos y aumentar la capacidad de producción.

Máquina cortadora de cola de pelo Gondor – Ideal para un procesamiento eficiente e inteligente

Si está buscando equipos que puedan mejorar la eficiencia de la producción y reducir los costos laborales, La máquina cortadora de cabezas de pescado es sin duda su mejor opción.. Con su función de corte totalmente automática, corta perfectamente sin dejar residuos, mientras la cabeza de pescado, cuerpo, y la cola se descargan por separado, haciendo que el posprocesamiento sea mucho más fácil. Además, El equipo admite regulación de velocidad de frecuencia variable., permitiéndole ajustar de manera flexible la velocidad de corte según los diferentes requisitos. Ya sea que esté procesando cola de pelo, pez cuchillo, u otros ingredientes en forma de tiras, esta máquina puede manejarlos perfectamente, Satisfacer una amplia gama de necesidades de procesamiento.. Además, la operación es sencilla, Requiriendo sólo dos operadores para gestionar eficientemente., lo que aumenta significativamente la capacidad de producción. Por lo tanto, La máquina cortadora de cola de pelo es ideal para diversas plantas de procesamiento y servirá como un valioso asistente para mejorar la eficiencia de su producción..