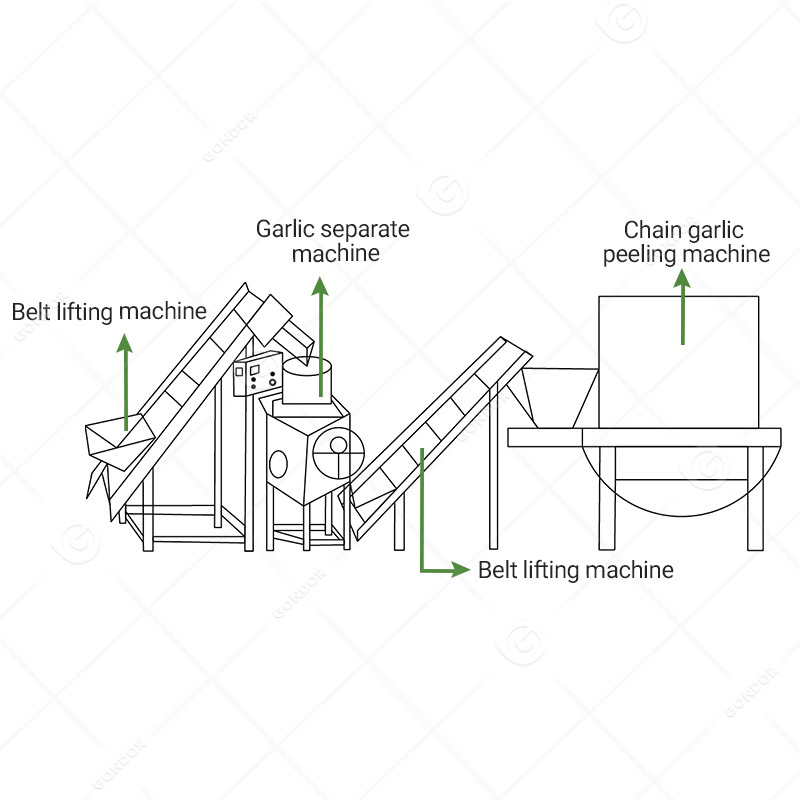

Itu lini produksi mengupas bawang putih adalah sekumpulan orang yang sangat cerdas, efisien, dan sistem produksi yang andal. Hal ini terutama digunakan untuk pemisahan dan pengupasan bawang putih dalam skala besar, termasuk lift, pemisah bawang putih, mesin pengupas bawang putih rantai dan mesin lainnya. Mesin Gondor menyediakan jalur pemrosesan pengupasan bawang putih untuk pelanggan kami dan klien kami tersebar di seluruh dunia. Dan mereka memilih untuk membeli mesin dari Gondor untuk meningkatkan produktivitas dan kualitas dengan mesin atau lini canggih kami. Hubungi kami untuk konsultasi gratis tentang lini produksi pengupas bawang putih otomatis di Gondor Group!

Jalur Produksi Pengupasan Bawang Putih Efisiensi Tinggi di Gondor

Berbagai Model Lini Produksi Pengupasan Bawang Putih Gondor

Di mesin Gondor, kami menawarkan berbagai model lini produksi pengupasan bawang putih otomatis yang dapat disesuaikan berdasarkan kebutuhan spesifik pelanggan kami dan kapasitas produksi yang diinginkan. Apakah Anda ingin membeli pengaturan skala kecil untuk produksi lokal atau yang lebih besar, jalur kelas industri untuk produksi massal, lini mesin pengupas bawang putih Gondor dapat disesuaikan untuk memenuhi permintaan Anda. Lebih-lebih lagi, lini pemrosesan bawang putih kami mengadopsi sistem canggih yang dapat memastikan transisi mulus dari bawang putih utuh ke siung yang dikupas sempurna. Lebih-lebih lagi, dan bahkan lebih signifikan, itu dapat mempertahankan produktivitas dan kualitas tinggi di seluruh proses. Berikut adalah beberapa model utama lini produksi pengupas bawang putih dari grup Gondor:

| Produk | Model | Tenaga motorik | Kapasitas | Berat Kotor | Dimensi(cm) |

| Konveyor | GD-130 | 0.75kw | / | 130kg | 220*70*150 |

| Mesin Pemisah Bawang Putih | GD-500 | 1.12kw | 500kg/jam | 135kg | 80*74*114 |

| Mesin Pemisah Bawang Putih | GD-1000 | 2.05kw | 1000kg/jam | 165kg | 150*73*120 |

| Mesin Pengupas Bawang Putih | GD-400 | 1.0kw | 400kg/jam | 240kg | 160*50*145 |

| Mesin Pengupas Bawang Putih | GD-600 | 1.0kw | 600kg/jam | 280kg | 180*58*152 |

| Mesin Pengupas Bawang Putih | GD-1000 | 2.25kw | 1000kg/jam | 450kg | 310*100*200 |

Dijual Mesin Pengupas Bawang Putih Hemat Energi di Gondor

Mesin Pengupas Bawang Putih Output Tinggi dari Mesin Gondor

Mengapa Berinvestasi di Lini Produksi Pengupasan Bawang Putih?

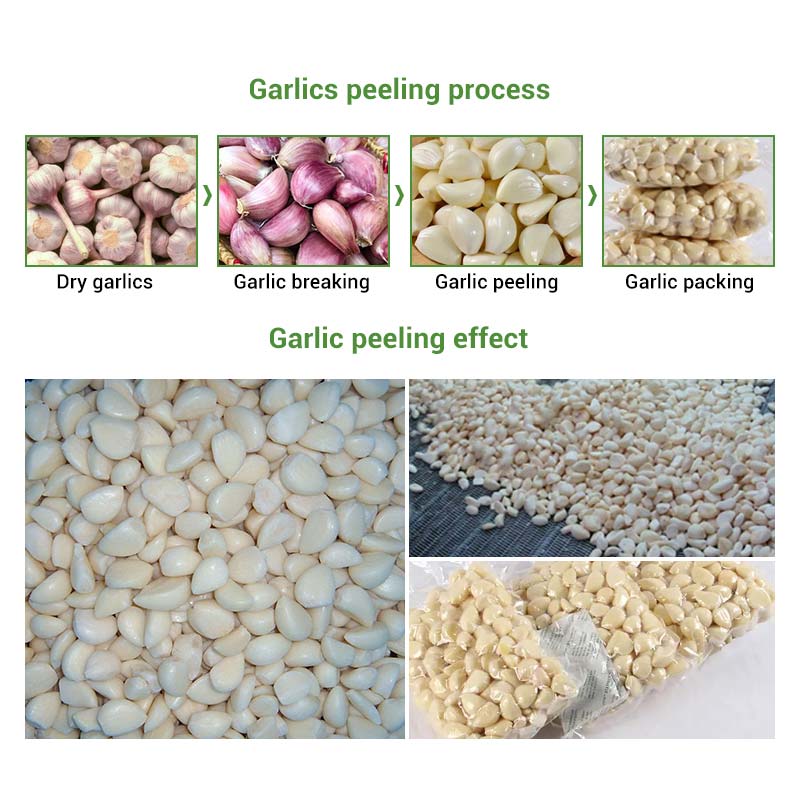

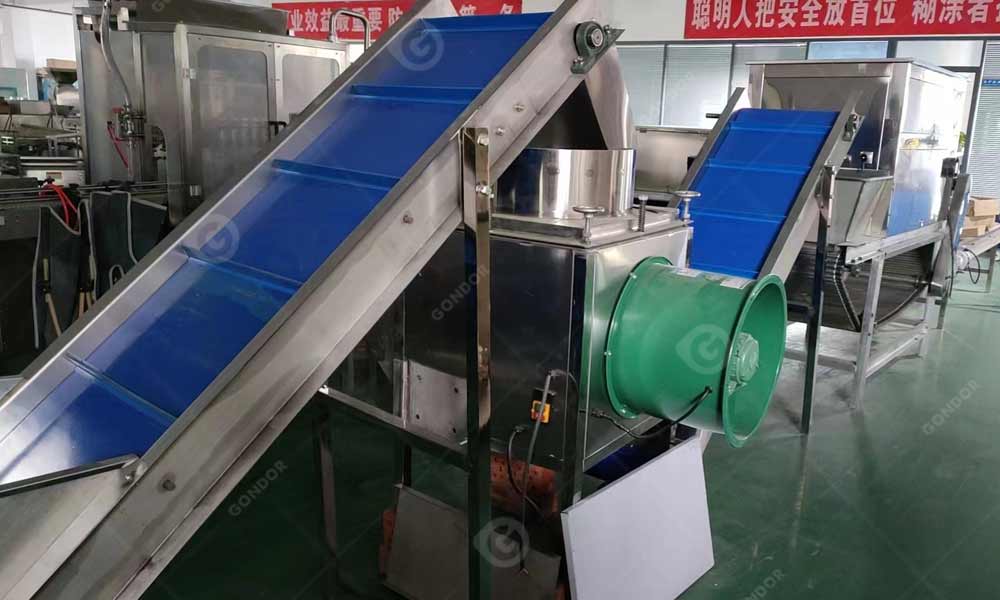

Lini produksi pengupasan bawang putih mengangkut bawang putih melalui jalur baja tahan karat dan menggunakan udara bertekanan untuk melepaskan kulit bawang putih, mencapai pengelupasan bebas kerusakan. Dan itu terdiri dari 304 baja tahan karat, yang cukup tahan lama. Di samping itu, penggunaan teknologi tinggi untuk mengupas bawang putih dan bawang bombay berkualitas tinggi saat ini merupakan alat pengupas yang paling ideal.

Di sisi lain, metode pengupasan kering pada jalur pemrosesan pengupasan bawang putih otomatis tidak memerlukan air, sehingga lini produksi tidak hanya dapat menghindari pemborosan sumber daya air tetapi juga mematuhi kebijakan lingkungan saat ini. Selain itu, ini mengurangi biaya tenaga kerja dan memastikan konsistensi dan stabilitas kualitas produk, yang dapat menjamin peningkatan produktivitas dan peningkatan efisiensi operasional. Sementara itu, adapun produksi industri skala besar dan usaha kecil menengah, presisi tinggi dan keandalan peralatan berkontribusi pada pengurangan limbah secara signifikan, yang dapat memastikan penggunaan bahan baku secara optimal dan memaksimalkan keuntungan.

Jalur Pengupasan Bawang Putih untuk Produksi Skala Besar

Aplikasi Jalur Pengolahan Pengupasan Bawang Putih Otomatis

Jalur pemrosesan pengupasan bawang putih otomatis pada mesin Gondor adalah bagian yang ideal untuk berbagai sektor termasuk industri pengolahan makanan, restoran, perusahaan pengolahan hasil pertanian, produsen bumbu dan rempah-rempah, dan lembaga penelitian dan pengembangan pangan. Lini produksi peeling ini memiliki fasilitas yang lengkap dan dapat beroperasi secara efisien, sehingga dapat menjamin pengupasan bawang putih secara cepat bagi investor yang berbeda. Jika Anda memiliki permintaan untuk jalur pengolahan pengupasan bawang putih ini atau jalur produksi lainnya, jangan ragu untuk menghubungi tim kami untuk informasi lebih lanjut dan dukungan pribadi di sini!

Fitur Utama Jalur Produksi Pengupasan Bawang Putih Otomatis Gondor

Dengan memilih membeli lini produksi pengupas bawang putih otomatis di Gondor, bisnis bisa mendapatkan keuntungan dari kombinasi efisiensi yang tinggi, kualitas unggul, dan keandalan. Dengan cara ini, Mesin Gondor dapat tetap kompetitif dalam industri pengolahan makanan yang bergerak cepat. Selain itu, Lini produksi pengupas bawang putih otomatis Gondor dirancang untuk efisiensi dan kecepatan maksimum. Kami memanfaatkan teknologi canggih untuk mengupas bawang putih dalam jumlah besar dalam waktu yang lebih singkat, mengurangi biaya tenaga kerja dan meningkatkan produktivitas. Proses pengupasannya disederhanakan untuk memastikan setiap siung terkelupas sempurna dalam hitungan detik. Periksa di bawah untuk mengetahui beberapa fitur utama dari lini produksi ini dan hubungi kami untuk detail produk lebih lanjut!

- Ini dirancang untuk menangani bawang putih dengan lembut, yang dapat menjaga keutuhan dan kualitas cengkeh. Dan jelas bahwa lebih sedikit limbah dan hasil yang lebih tinggi sangat penting bagi bisnis yang ingin memaksimalkan hasil produksinya.Kerusakan Minimal pada Bawang Putih

- Pabrik kami mengadopsi baja tahan karat berkualitas tinggi untuk memproduksi jalur pengupas bawang putih, dan mudah dibersihkan serta tahan terhadap korosi. Di samping itu, desainnya yang unik juga meminimalkan risiko kontaminasi, yang menjamin standar keamanan pangan tertinggi.Pengoperasian yang Higienis dan Aman

- Untuk tujuan memenuhi kebutuhan unik berbagai bisnis, Gondor menawarkan lini produksi pengupasan bawang putih yang disesuaikan. Karena itu, pelanggan global dapat memilih dari berbagai opsi dan konfigurasi dari pabrik kami.Solusi yang Dapat Disesuaikan

- Sistem otomatis akan memperlancar seluruh proses pengelupasan. Dan itu dapat memastikan operasi yang lancar dan konsisten selama keseluruhan proses, yang dapat mengurangi kebutuhan intervensi manual.Otomatisasi Terintegrasi

- Mesin tersebut menggunakan listrik sebagai sumber energinya, menampilkan konsumsi energi yang rendah. Selain itu, metode pengupasan kering tidak mencemari lingkungan dan mematuhi kebijakan lingkungan.Konservasi energi

- Ini jalur produksi dapat digunakan di berbagai industri seperti pabrik pengolahan makanan, layanan katering, dan perusahaan pengolahan hasil pertanian.Berlaku secara luas

- Perangkat ini memiliki antarmuka intuitif yang sederhana, membuatnya mudah dioperasikan. Mudah dibersihkan dan dirawat, Sementara itu, mengurangi waktu henti.Operasi sederhana

- Lini produksi dirancang dengan otomatisasi penuh, memungkinkan pengelupasan yang cepat dan penghematan biaya tenaga kerja yang signifikan.Efisiensi Tinggi

- Setiap siung bawang putih menghasilkan efek pengelupasan yang konsisten untuk memastikan stabilitas kualitas produk.Jaminan Kualitas

- Peralatan ini memiliki rasio kinerja terhadap harga yang tinggi. Ini memiliki pengembalian investasi yang cepat melalui pengurangan biaya tenaga kerja dan efisiensi produksi yang tinggi.Efektivitas Biaya

- Selain bawang putih, bisa juga mengupas bawang. Pelanggan dapat menyesuaikan lini produksi untuk memenuhi kebutuhan bisnis tertentu.Multifungsi

Mengapa Memilih Mesin Gondor?

Mesin Gondor, sebagai produsen dan pemasok lini produksi pengupas bawang putih terkemuka, menonjol di pasar karena komitmen kami terhadap kualitas, inovasi, dan kepuasan pelanggan. Setiap staf di Gondor akan melakukan upaya kami untuk membantu pelanggan kami memecahkan masalah mereka dan memberikan solusi luar biasa untuk memaksimalkan keuntungan bisnis mereka. Terlebih lagi, Mesin Gondor melayani pelanggan di seluruh dunia, dan banyak di antara mereka yang secara konsisten memberikan masukan positif kepada kami, melakukan pemesanan berulang, dan memperkenalkan klien baru kepada kami. Berikut adalah beberapa alasan mengapa bisnis lebih memilih mesin kami:

Keahlian dan Pengalaman

Dengan manufaktur bertahun-tahun, merancang dan mengekspor pengalaman dalam mesin pengolahan makanan, kami sangat memahami tantangan unik dalam pengolahan bawang putih dan terus meningkatkan lini pengolahan kami untuk mengatasinya secara efektif. Untuk alasan ini, Mesin Gondor selalu dapat mempertahankan posisi terdepan dalam industri.

Kustomisasi Tersedia

Desainer profesional kami memiliki pengalaman luas selama bertahun-tahun dalam desain mekanik, sehingga kami dapat memberikan solusi yang disesuaikan bagi klien kami untuk memenuhi kebutuhan spesifik mereka. Oleh karena itu, kami dapat menjamin bahwa lini produksi pengupasan bawang putih otomatis kami terintegrasi dengan operasi Anda yang ada.

Dukungan Purna Jual

Tim dukungan kami yang berdedikasi selalu tersedia online untuk memberikan dukungan purna jual, dan mereka dapat membantu pelanggan menyelesaikan masalah dan meringankan kekhawatiran mereka. Selain itu, mereka selalu siap membantu klien kami dalam pemasangan, pelatihan, dan pemeliharaan, memastikan bahwa lini produksi Anda beroperasi dengan lancar.

Rangkaian Produk Inklusif

Dengan manufaktur bertahun-tahun, merancang dan mengekspor pengalaman dalam mesin pengolahan makanan, kami sangat memahami tantangan unik dalam pengolahan bawang putih dan terus meningkatkan lini pengolahan kami untuk mengatasinya secara efektif. Untuk alasan ini, Mesin Gondor selalu dapat mempertahankan posisi terdepan dalam industri.

Keandalan dan Kepercayaan

Karena kinerja yang konsisten dan kepuasan pelanggan, lini produksi kami telah dipercaya oleh klien di seluruh dunia. Banyak pelanggan dari grup Gondor yang secara konsisten memilih kami karena permintaan mereka yang terus meningkat dan peningkatan bisnis mereka, yang tentunya membuktikan keandalan dan kualitas lini produksi kami.

Kemampuan Integrasi

Perusahaan kami sangat ahli dalam menggabungkan mesin yang berbeda ke dalam jalur produksi yang mulus, yang menjamin kelancaran dan efisiensi operasi, dan meningkatkan produktivitas. Selain itu, kami membantu bisnis mencapai hasil yang lebih tinggi dan mempertahankan kualitas yang konsisten. Lebih-lebih lagi, Gondor dapat memperluas jalur produksi yang berbeda dengan mudah untuk memenuhi permintaan Anda.

Bermitra Dengan Grup Gondor

Seperti yang kita ketahui, ini adalah pilihan cerdas bagi bisnis untuk berinvestasi pada lini produksi pengupasan bawang putih kami ketika Anda ingin meningkatkan operasi pemrosesan bawang putih. Dengan efisiensinya yang tinggi, kualitas yang konsisten, dan efektivitas biaya, Lini produksi pengupas bawang putih otomatis Gondor akan membantu Anda mencapai tujuan produksi dan mempertahankan keunggulan kompetitif di pasar. Silakan ikuti kami berita transaksi bawang putih atau hubungi kami untuk mempelajari lebih lanjut detail produk tentang lini pengupas bawang putih kami dan memilih model yang tepat untuk bisnis Anda! Kami akan membantu Anda membawa bisnis pengolahan bawang putih Anda ke tingkat selanjutnya!