Gondor Vertical Chocolate Tempering Machine Introduction

Itu vertical chocolate tempering machine is an essential solution for confectioners seeking professional results. Designed for precision, this industrial chocolate tempering machine features an advanced temperature control system that ensures your chocolate maintains a constant, optimal state throughout the process. This creates a final product with a superior snap and a brilliant, uniform sheen.

Gondor Vertical Chocolate Tempering Machine Models

Below are the models of vertical chocolate tempering machines. If you have other customized needs, please contact us and we will provide you with a free consultation and a detailed quotation.

| Model | Heating Temperature | Kisaran Suhu | Kapasitas | Ukuran | Berat | Kekuatan |

| GD-CTMV | 0-60°C | 25-32°C | 60L | 1150*700*1600mm | 200kg | 8000w |

Working Principle of Vertical Chocolate Tempering Machine

The working principle of the vertical chocolate tempering machine primarily involves two key stages: heating and cooling. Utilizing electric heating or a hot water jacket, the machine rapidly brings the chocolate to the required temperature and then maintains it within the ideal range through an intelligent control system. The built-in stirring device ensures that the machine mixes the chocolate evenly during the heating process, adjusting the crystal structure to enhance the final product’s texture.

Application of Gondor Vertical Chocolate Tempering Machine

The vertical chocolate tempering machine achieves precise temperature control and uniform mixing, making it an indispensable tool across a wide range of industries. Its compact vertical design allows it to fit seamlessly into various production environments, from artisanal shops to high-capacity facilities.

Gondor Vertical Chocolate Tempering Machine Processing Flow

Melangkah 1: Raw Material Loading & Pemanasan awal

Place the chocolate blocks or chips into the melting tank. Power on the machine and initiate the preheating mode to allow the raw materials to begin their initial softening phase.

Melangkah 2: Activating the Mixing System

Once the chocolate at the base of the tank has sufficiently melted into a liquid state, activate the stirring device to ensure even heat distribution and prevent localized scorching.

Melangkah 3: Engaging the Extraction System

When approximately one-third of the tank’s contents have melted, turn on the material extraction/pump system to facilitate internal circulation and achieve a uniform consistency.

Melangkah 4: Temperature Adjustment & Produksi

Once the chocolate is fully melted and smooth, activate the precision temperature adjustment system. After the tempering process is complete, use the foot pedal for controlled sampling or begin the pouring and molding process.

How to Clean and Maintain This Vertical Thermostat?

The cleaning and maintenance of the vertical chocolate tempering machine is very simple: After the production process is completed, add an appropriate amount of warm water directly into the cylinder and start the stirring device. Utilizing the circulating power, fully dissolve and scrub the remaining chocolate on the cylinder wall and accessories. Kemudian, discharge it through the discharge port uniformly. It is recommended to repeat this process until the water is clear. Akhirnya, wipe the system clean with a dry cloth to ensure complete drying. Selain itu, regularly check the seals and follow the detailed manual provided with the equipment for daily lubrication to ensure the equipment operates stably for a long time.

Gondor Vertical Chocolate Tempering Machine Features

- Siemens Intelligent Control: Equipped with a Siemens PLC touchscreen to achieve precise automated management of both temperature and stirring.

- Dual Filtration Protection: Features a stainless steel filter that effectively removes solid particles and prevents pipe blockages, significantly enhancing the purity of the final product.

- Water-Circulation Tempering Technology: Utilizes cooling water circulation to ensure minimal temperature fluctuations, giving the chocolate a delicate and professional gloss.

- Tahan lama & Desain yang Mudah Dibersihkan: Built with 5mm thickened stainless steel mixing blades for uniform agitation; the design supports quick disassembly, greatly simplifying cleaning and maintenance tasks.

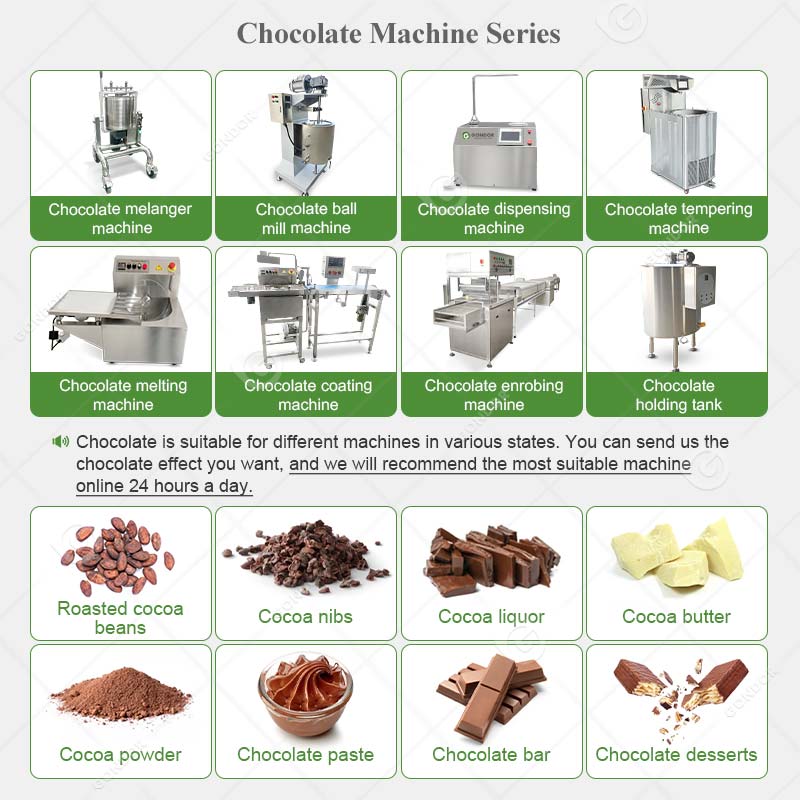

Recommended Complementary Equipment

Untuk membangun yang lebih efisien, fully automated chocolate production line, the following equipment can be integrated into your workflow:

- Pabrik Bola Coklat: Used for high-efficiency grinding and refinement of raw materials, providing a uniform base mass for the tempering process.

- Penggiling Coklat: Further enhances the fineness of the material, ensuring the chocolate achieves a silky mouthfeel and excellent gloss.

- Mesin Penyimpanan Cokelat: Precisely molds and deposits the tempered chocolate, enabling high-efficiency automated molding and filling operations.