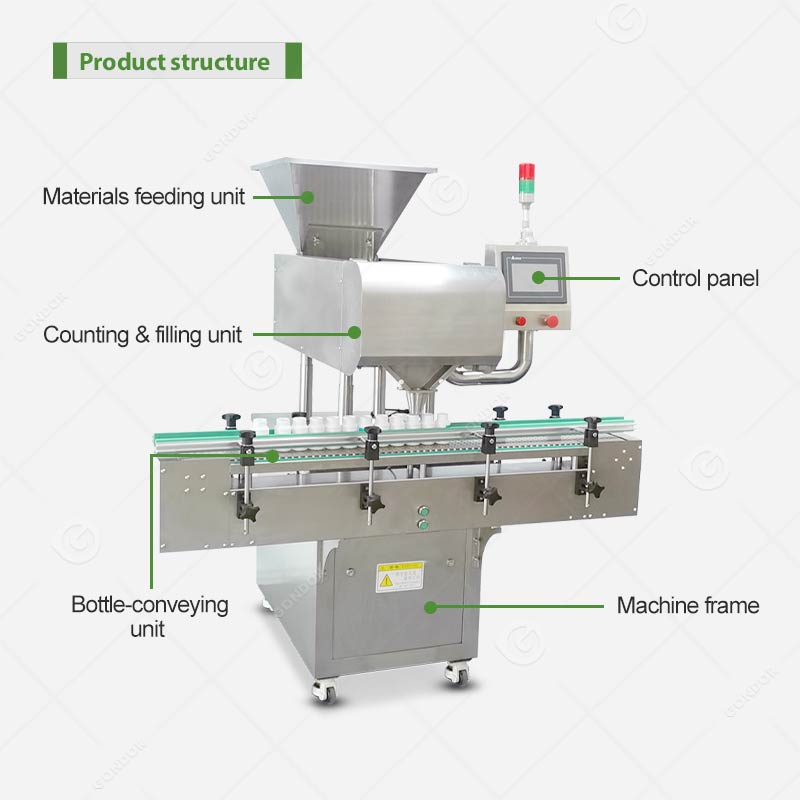

Le machine de comptage automatique est un dispositif électronique automatique innovant qui utilise une technologie de détection photoélectrique avancée pour garantir une précision de comptage ≥99,97 %. Il est largement utilisé dans diverses industries, y compris les graines, produits de santé, et de la nourriture, offrant des fonctions de comptage et de remplissage entièrement automatisées. Les principales caractéristiques de l'équipement comprennent une décharge uniforme et stable, le “pas de bouteille, pas de compte” fonction, et arrêt automatique lorsqu'il n'y a aucune bouteille présente. En plus, l'appareil bénéficie d'une forte compatibilité, s'adapter à une large gamme de produits et de types de bouteilles. La conception du vibrateur à trois étages est particulièrement efficace pour manipuler des matériaux irréguliers ou collants. En outre, de haute qualité 316 l'acier inoxydable est utilisé partout, garantissant à la fois durabilité et hygiène. Le système de contrôle à écran tactile est convivial et prend en charge une interface multilingue, ce qui le rend idéal pour les clients internationaux. Par conséquent, le compteur de grains est un excellent choix pour les entreprises qui cherchent à améliorer l'efficacité et la précision de la production.

|

Produit |

Machine à compter |

| Modèle |

GD-8 |

|

Volume de la trémie |

24L |

| Capacité de production |

1-30 bouteilles/m |

|

Plage de volumes |

10-9999 pièces |

| Alimentation |

220V 50 Hz 0,6 kW |

|

Dimension |

1360*1320*1600mm |

| Poids |

180kilos |

|

Précision |

≥99 % |

Industries applicables de la machine de remplissage de comptage du Gondor

La machine de remplissage compteuse est une machine de haute précision, équipement de comptage et de remplissage électronique entièrement automatique adapté à une variété d’industries. Il peut effectuer efficacement et avec précision le comptage et l'emballage des matériaux. Qu'il s'agisse d'un produit standardisé ou d'un produit complexe, matériau de forme irrégulière, la machine de remplissage de comptage peut fournir une solution fiable pour aider à améliorer l'efficacité de la production et garantir la qualité du produit. Voici les principales industries applicables de cet équipement:

Les avantages supérieurs de l’utilisation de la machine à compter les capsules Gondor

Avec son design innovant et sa technologie avancée, la machine de comptage fournit des solutions de comptage et de remplissage automatiques efficaces et précises pour diverses industries. Cet équipement utilise une technologie de détection photoélectrique et un système de contrôle intelligent, qui présente d'excellents avantages en termes de performances, peut améliorer considérablement l’efficacité de la production, réduire les coûts de main d'œuvre, et assurer la cohérence de la qualité des produits. Voici les principaux avantages de l’utilisation d’une machine à compter:

Machine de comptage automatique Gondor – Idéal pour la haute précision et l'automatisation

La machine de comptage automatique est un équipement innovant qui utilise une technologie de détection photoélectrique avancée pour garantir une précision de comptage allant jusqu'à 99.97%. Grâce à sa forte compatibilité, système d'exploitation intelligent, et système d'alimentation par vibration stable, le compteur à grains est largement utilisé dans diverses industries telles que l'alimentation, produits de santé, graines, produits chimiques, et plus. En plus, sa structure entièrement en acier inoxydable est facile à nettoyer et répond à des normes d'hygiène strictes, assurer un environnement de production sûr et conforme. Avec son fonctionnement par écran tactile simple et intuitif, avec support multilingue, la machine est conçue pour être conviviale pour les clients du monde entier. Ne manquez pas cette occasion : commandez la machine de comptage et de remplissage Gondor dès aujourd'hui pour améliorer l'efficacité et la précision de la production., aider votre entreprise à prospérer. Si vous êtes intéressé, veuillez remplir la case de demande ci-dessous pour en savoir plus sur les détails du produit ou recevoir un devis personnalisé.