Ligne de production de pain industrielle automatique Gondor

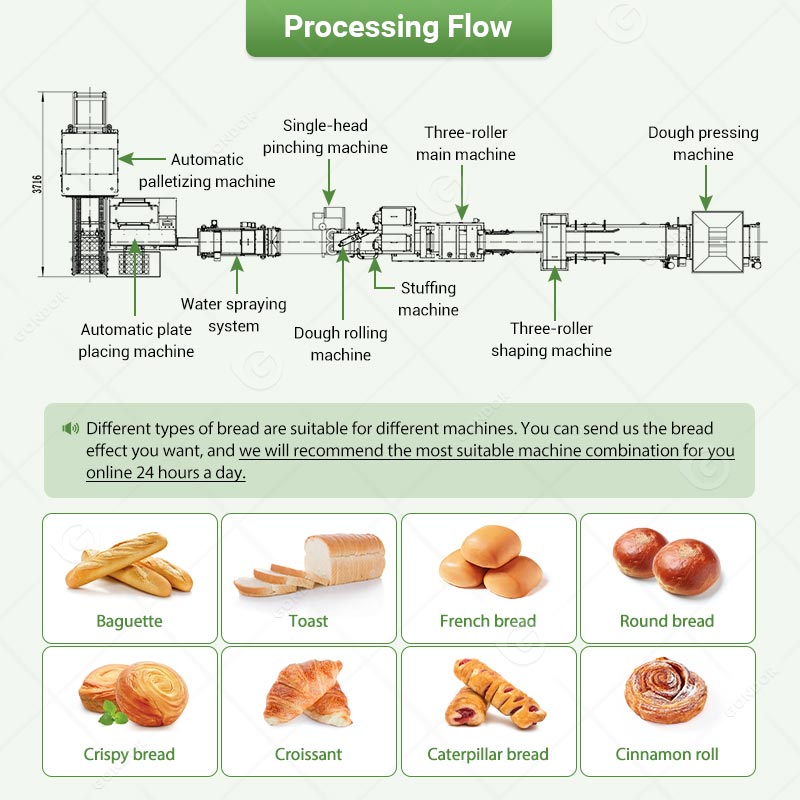

Le multifonctionnel ligne de production de pain est un système automatisé avancé conçu pour la production de pain à grande échelle. Il gère chaque étape, de la fabrication et du façonnage de la pâte jusqu'au farce., pâtisserie, et emballage – avec précision et efficacité, garantir une qualité constante. Équipé d'un système de contrôle PLC intelligent, il prend en charge la conception modulaire et la personnalisation, s'adapter à différents types de pain comme le pain grillé, baguettes, et blé entier. Fonctionner efficacement, il réduit les coûts de main-d'œuvre et augmente la capacité de production, ce qui le rend idéal pour les boulangeries, cuisines centrales, et entreprises de transformation des aliments.

|

P.nom du produit |

Paramètres du produit |

| Machine à presser les nouilles entièrement automatique |

Largeur de pressage des nouilles <500mm Tension/puissance: 380V/3,0 kW Dimensions: 1300*1000*1400mm Poids: environ 450 kg |

|

Machine à fendre et façonner des bandes de nouilles |

Largeur du rouleau 320mm

Tension/puissance: 380V/1,5 kW Dimensions: 3300*700*1300mm Poids: environ 100kg |

| Machine à rouler à trois passes |

Largeur du rouleau 300-500mm Tension/puissance 380V/3,2kw Dimensions 4100*770*1500mm Poids environ 400kg |

|

Machine à refendre les bandes de pâte |

Tension/puissance 380V/220V/0,2kw

Dimensions 1250*920*700mm Poids environ 70kg |

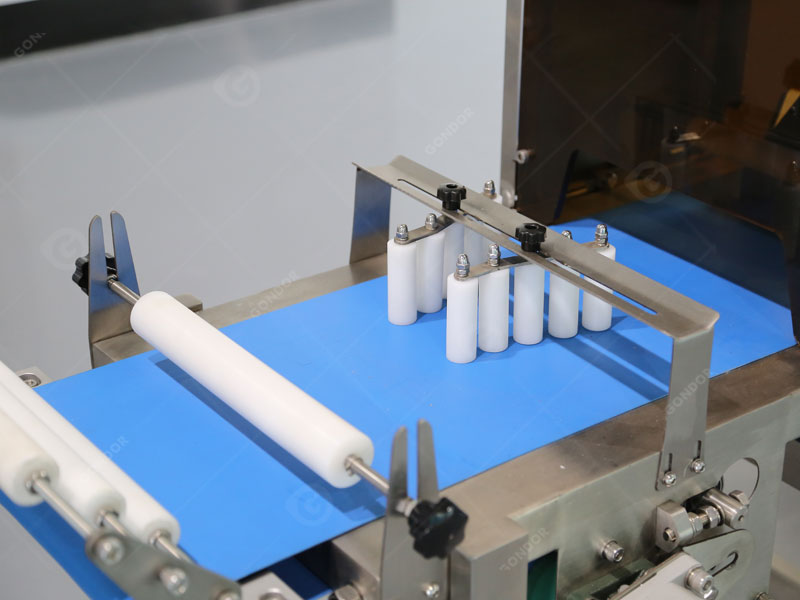

| Machine à rouler la pâte |

Tension/puissance 220V/0,32kw Dimensions1750*920*940mm Poids environ 90kg |

|

Machine de remplissage |

Diamètre du port d'alimentation: 6-38mm (personnalisable)

Tension/puissance 220V/0,75kw Dimensions 1000*410*1320mm horizontale Dimensions 500*400*1430mm verticales Poids environ 90kg |

| Table de découpe divisée (servomoteur) |

Capacité de production 50-180 pièces/minute Tension/puissance 220V/380V/0,75kw Dimensions 1200*620*1300 Poids environ 180kg |

|

Machine à pincer les fleurs |

Capacité de production 2000-6000 pièces/heure

Tension/puissance 220V/0,75kw Dimensions 1350*750*1200mm Poids environ 180kg |

| Machine à plateaux (servomoteur) |

Capacité de production 1200-12000 pièces/heure Tension/puissance 220V/380V/0,76kw Dimensions 3000*1100*1300mm Poids environ 180kg |

Portée du marché d’application de la chaîne de production de pain industriel

Avec sa grande efficacité, flexibilité, et le renseignement, la ligne de production de pain multifonctionnelle est largement utilisée dans diverses industries et scénarios, répondre efficacement aux divers besoins des différents marchés. Que ce soit pour une production industrielle à grande échelle ou sur mesure, exigences relatives aux petits lots, cette ligne de production augmente considérablement la capacité de production et réduit les coûts d'exploitation. Par conséquent, il est devenu une solution indispensable et efficace pour l'industrie agroalimentaire. Ce qui suit met en évidence ses principaux marchés d’application:

Répondre aux besoins de la production de masse et garantir la cohérence et la haute qualité des produits.

Soutenir la production de plusieurs types de produits et améliorer la compétitivité du marché.

Produire efficacement des produits standardisés pour fournir un approvisionnement stable aux magasins.

Produire rapidement et efficacement une variété de pains pour répondre aux besoins de logistique et de distribution.

Soutenir la production sur mesure et fournir aux supermarchés des produits de boulangerie riches et diversifiés.

Répondre aux besoins du marché international et fournir des produits de boulangerie diversifiés et de haute qualité.

Produire du pain conforme aux concepts de santé, comme le blé entier, pains sans sucre et autres pains spéciaux.

Utilisé pour la recherche et le développement de technologies alimentaires, recherche en technologies de production et enseignement expérimental.

Avantages de travail importants de la ligne de pain automatique Gondor

La ligne de pain automatique multifonctionnelle a démontré une compétitivité remarquable dans la production alimentaire grâce à sa haute efficacité, intelligence, et flexibilité. En tirant parti d’une technologie avancée et d’une conception soignée, il optimise non seulement le processus de production, mais réduit également considérablement les coûts tout en améliorant la qualité et la cohérence du produit.. Voici ses principaux avantages de travail:

Choisissez la ligne de production de pain Gondor – Saisissez les opportunités du marché

La ligne de production de pain Gondor offre une solution complète pour la production de pain à grande échelle grâce à sa haute efficacité, intelligence et flexibilité. De la préparation de la pâte, moulage, fermentation jusqu'à l'emballage final, toute la ligne est automatiquement connectée pour garantir un processus de production précis et efficace et une qualité de produit constante. L'équipement adopte une conception modulaire et un système de contrôle PLC intelligent, qui peut s'adapter de manière flexible à différents types de production de pain, répondre aux besoins différenciés des clients, réduire considérablement les coûts de main-d’œuvre et améliorer la capacité de production globale. Convient pour la boulangerie, cuisine centrale et toutes sortes d'entreprises de transformation des aliments, pour aider à optimiser le processus de production et à améliorer les avantages économiques.

S'il est nécessaire d'améliorer encore la productivité et l'efficacité de la cuisson, il est recommandé de l'utiliser avec un four tunnel industriel pour réaliser un traitement thermique continu et uniforme du moulage à la cuisson, raccourcir le cycle de cuisson et stabiliser la couleur et le goût des produits finis. Choisir Gondor, c'est choisir la double garantie de haute efficacité et de qualité.. Bienvenue à commander immédiatement ou remplissez la case de demande ci-dessous pour nous contacter pour des solutions personnalisées et un service d'assistance professionnel.!