Introduction de la ligne de transformation des noix de cajou du Gondor

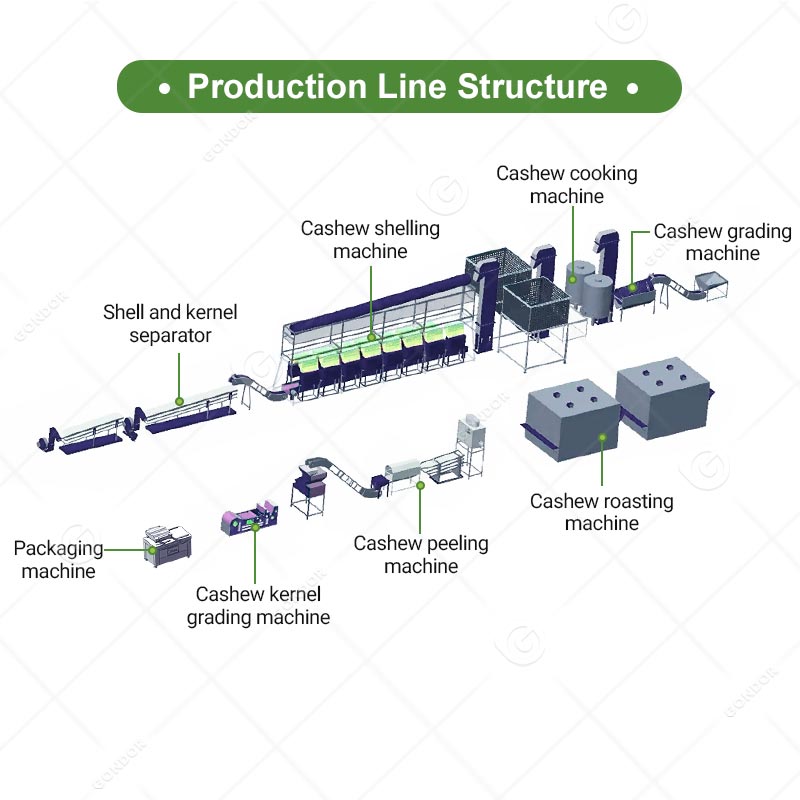

Le Ligne de traitement des noix de cajou utilise les noix de cajou brutes comme matière première et les transforme en amandes entièrement emballées grâce à un système de production entièrement automatisé pour répondre aux besoins de divers fabricants de produits alimentaires. L'ensemble ligne de machines de traitement de noix de cajou comprend une niveleuse de noix de cajou brute, un bateau à vapeur, un décortiqueur, un séparateur de noyau, un torréfacteur et un séchoir, un éplucheur, un niveleur de noyau, et une machine d'emballage automatisée.

Modèles de lignes de transformation de noix de cajou du Gondor

Ce qui suit est le tableau des paramètres techniques clés de l'équipement de base dans la chaîne de production de transformation des noix de cajou., couvrant des informations de base telles que le nom de l'équipement, pouvoir, tension, poids, taille et capacité pour votre référence rapide. Si vous avez d'autres exigences de produits personnalisées, nous vous fournirons un service de consultation gratuit pour vous aider à répondre avec précision à vos besoins de production.

| Nom | Pouvoir(kW) | Tension(v) | Poids(kilos) | Taille(mm) | Capacité |

| Machine de classement des noix de cajou | 2.25kW | 380v | 1900kilos | 5500*1350*1800mm | 300-400kg/heure |

| Machine de cuisson de noix de cajou | 0.75kW | 380v | 1200kilos | 1100*1000*3550mm | 400kg/lot |

| Machine à décortiquer les noix de cajou | 2.2kW | 380/220v | 680kilos | 1450*1100*1600mm | 150-200kg/heure |

| Séparateur de coque et de noyau | 0.75kW | 380/220v | 280kilos | 6000*700*1000mm | / |

| Machine à rôtir les noix de cajou | 3kW | 380v | 2800kilos | 5250*2200*2300mm | 900-1000kg/lot |

| Machine à éplucher les noix de cajou | 3kW | 380/220v | 1800kilos | 9200*1600*2700mm | 200-300kg/heure |

| Machine de classement des grains de noix de cajou | 0.75kW | 380v | 550kilos | 2500*1200*1600mm | 150-200kg/heure |

| Machine d'emballage | 0.75kW | 220v | 240kilos | 900*600*1500mm | / |

Application de la ligne de production de noix de cajou du Gondor

La ligne de transformation de la noix de cajou a de multiples applications. Au-delà de ses capacités technologiques avancées, la ligne de transformation des noix de cajou est largement utilisée dans l'industrie alimentaire pour produire des noix de cajou grillées et de la pâte de cajou, et servir d'ingrédient dans les confiseries et les produits de boulangerie. En plus, il joue un rôle clé dans l'industrie des aliments santé, permettre la production de suppléments nutritionnels et d’alternatives laitières végétaliennes.

Valeur d'application multi-domaines de la chaîne de traitement des noix de cajou du Gondor

Les systèmes centralisés traitent les noix de cajou fraîches, réduire les déchets, valeur croissante, et renforcer le pouvoir de négociation en aval.

Convient aux usines de transformation des aliments, réduire efficacement les coûts et contribuer à améliorer les marges bénéficiaires des produits.

Des méthodes de transformation saines préservent les nutriments, produire des produits sains et obtenir un avantage sur le marché des aliments santé.

La production standardisée offre une qualité constante de noix de cajou, prend en charge la production personnalisée, et réduit le temps de traitement.

Ligne de production de transformation de noix de cajou du Gondor Produits fabriqués

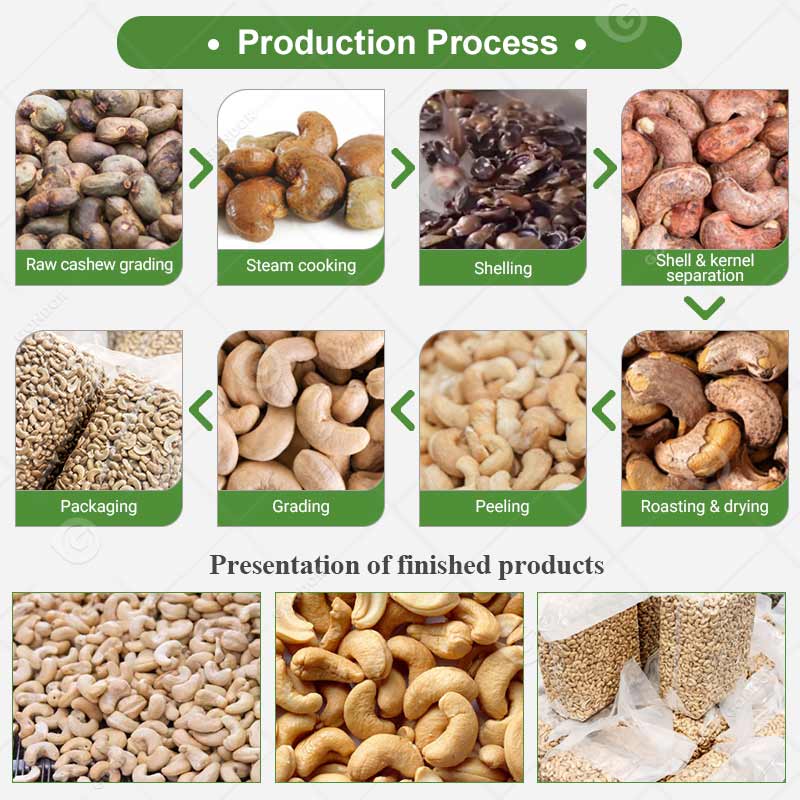

La ligne de production de noix de cajou prend les noix de cajou brutes comme matière première principale et les transforme en divers types de produits..

Caractéristiques de la ligne de transformation des noix de cajou du Gondor

La ligne de transformation des noix de cajou intègre des technologies de pointe pour offrir des performances exceptionnelles: il utilise la torréfaction de précision à basse température pour verrouiller efficacement les noix de cajou’ fraîcheur naturelle et valeur nutritionnelle, et adopte un pelage pneumatique doux pour éliminer efficacement les coquilles tout en préservant l'intégrité du noyau.

En plus, il utilise le classement basé sur l'IA pour garantir une qualité constante dans chaque lot, et adopte une automatisation de bout en bout pour rationaliser l'ensemble du processus de production, permettant ainsi une, économie de travail, et une fabrication fiable de la matière première au produit fini.

Nous avons sélectionné les composants d'équipement qui intéressent les clients pour fournir des descriptions détaillées de leurs principaux avantages..

Pourquoi choisir la ligne de traitement des amandes du Gondor?

- Haute automatisation, Coupe continue & Peeling

- Finement conçu, Construction en acier inoxydable

- Peeling pneumatique doux, >95% Noyau entier

- Classement de précision en plusieurs étapes, Haute précision

- Automatisation de bout en bout, Flux ininterrompu

- Entièrement soudé, Lisse & Apparence élégante

- Classement d'ouverture de type tambour, Tri uniforme