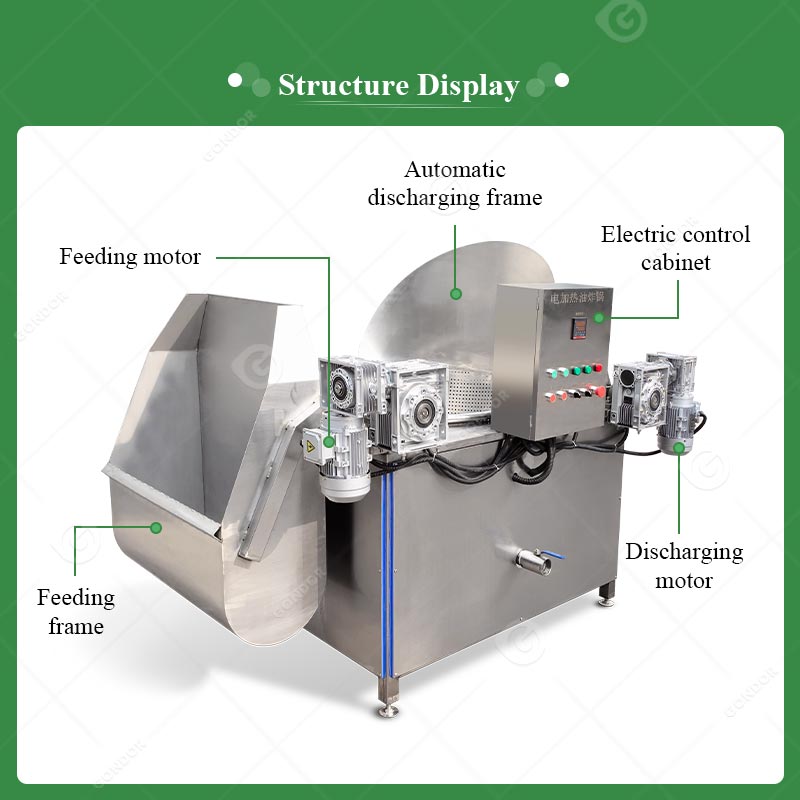

Un friteuse ronde industrielle est un équipement de friture efficace spécialement conçu pour les entreprises de transformation des aliments. L'équipement principal est en acier inoxydable SUS304 de qualité alimentaire, qui a une excellente résistance à la corrosion, sécurité, et stabilité. Sa structure innovante d'agitation synchrone de révolution et de rotation garantit que les ingrédients sont chauffés uniformément et ne collent pas., améliorant ainsi efficacement la qualité des produits et l'efficacité de la production.

Cet équipement est équipé d'un système intelligent de contrôle de la température, qui peut réaliser un contrôle précis de la température et une production automatique, éviter de brûler les ingrédients, et prolonger la durée de vie de la graisse. La friteuse industrielle est de structure compacte et peut être équipée d'un système de chargement et de déchargement automatique, ce qui peut considérablement économiser du travail et des coûts. C'est un choix idéal pour les entreprises de transformation des aliments souhaitant améliorer leur niveau d'automatisation..

| Modèle | Pouvoir | Tension | Diamètre du panier à frire | Taille de la machine |

| GD-800 | 36KW | 380V 50 Hz | 800 | 1050*1000*1700 |

| GD-1000 | 48KW | 380V 50 Hz | 1000 | 1250*1200*1700 |

| GD-1200 | 60KW | 380V 50 Hz | 1200 | 1450*1400*1700 |

| GD-1500 | 78KW | 380V 50 Hz | 1500 | 1750*1700*1700 |

Gamme de marchés d’application de la friteuse industrielle

La friteuse industrielle convient à une variété d'industries de transformation des aliments et peut répondre aux exigences de la production continue de friture:

- Frites/Croustilles

- Noix comme les cacahuètes

- Produits carnés Produits carnés

- Produits aquatiques

- Rouleaux de printemps/collations

- Transformation de collations de diverses collations

Avantages de performance exceptionnels de la friteuse industrielle

Pourquoi choisir notre friteuse ronde?

- Conception raisonnable, construction compacte, et économie de terres.

- Haut degré d'automatisation, réduire les coûts de main d'œuvre.

- Pas de fumée d'huile, aucune odeur de nourriture.

- La qualité de friture est stable, et la qualité du produit est améliorée.

- Il convient à une variété d'aliments et a une forte expansibilité.

- Sûr et fiable, facile à entretenir.

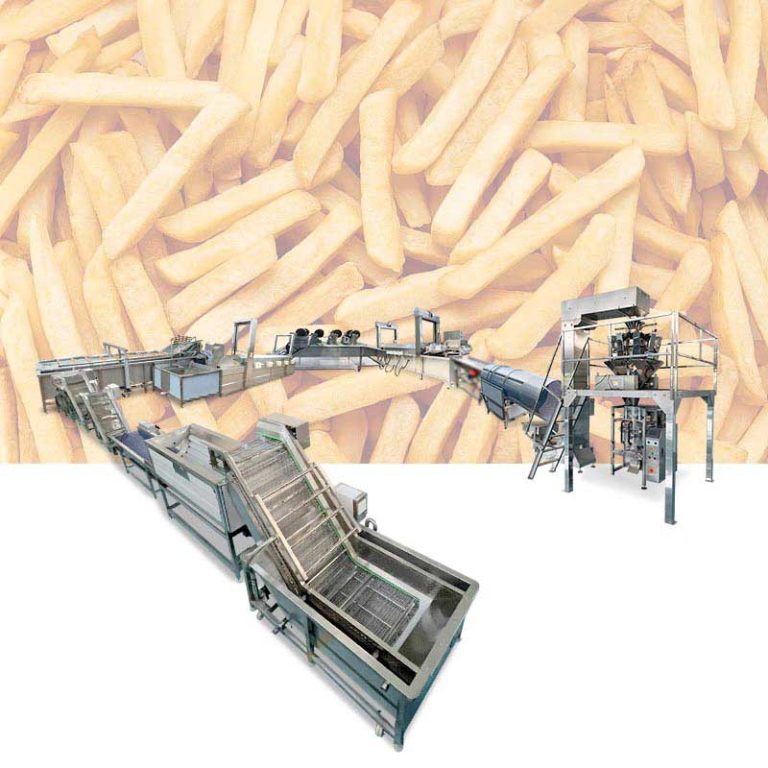

Équipement de support recommandé

Pour répondre aux besoins de la transformation alimentaire à grande échelle et automatique, nous fournissons également une variété d'équipements de soutien, qui peut former une ligne de production complète avec la machine à frire:

-

- Machine à laver les bulles

- Machine de déshuilage

- Machine d'assaisonnement de chips de pomme de terre

- Machine d'emballage