Machine de remplissage de liquide Gondor

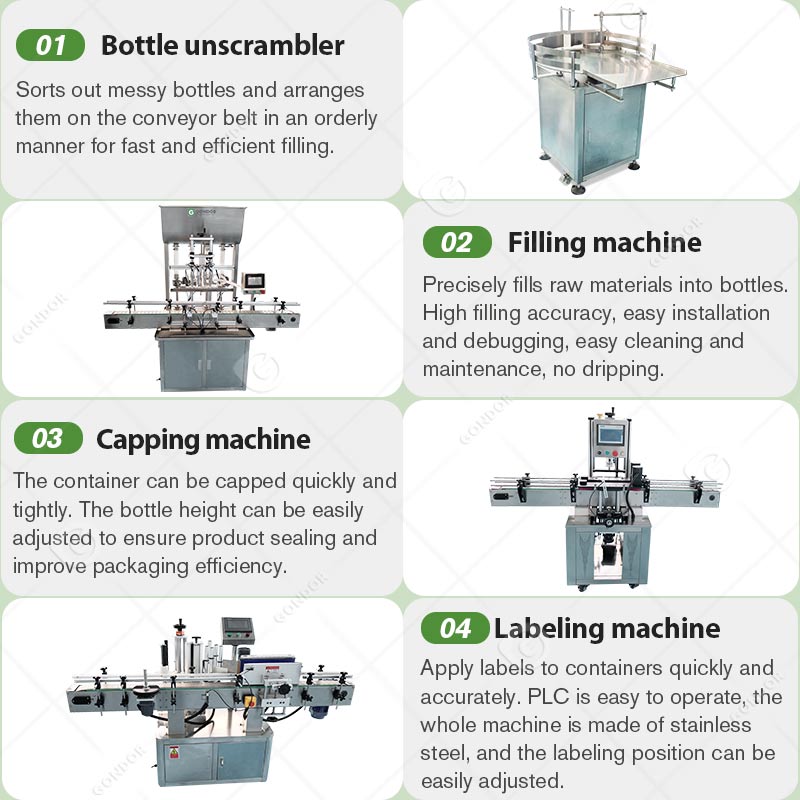

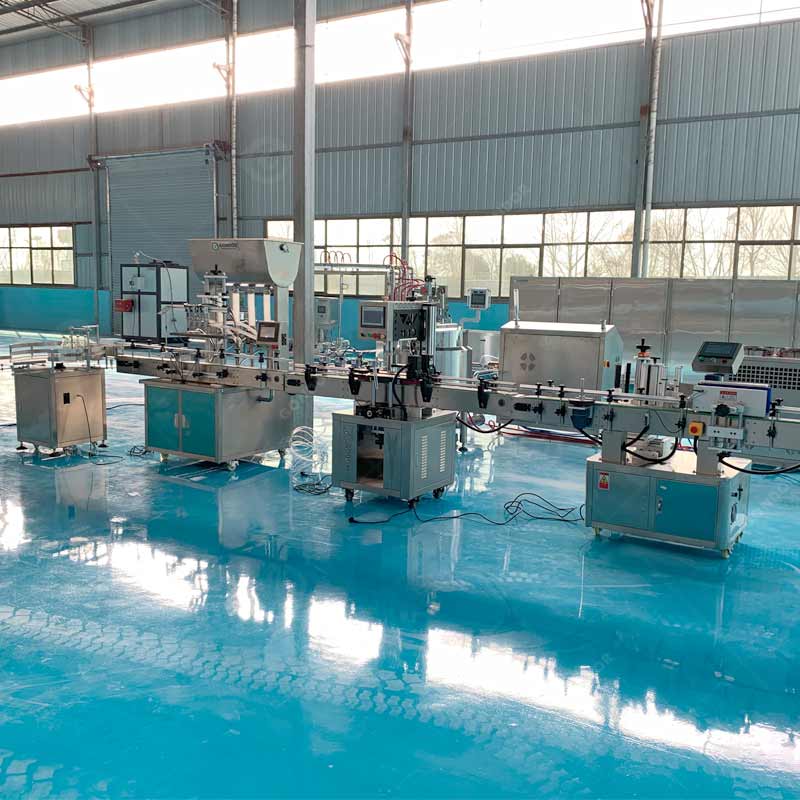

Ce ligne de remplissage de liquide intègre le tri automatique des bouteilles, remplissage précis, scellage à grande vitesse, et étiquetage intelligent, former un système d'emballage automatique complet. L'ensemble de la ligne adopte un système de contrôle intelligent PLC, combiné à un module de remplissage de haute précision, qui peut contrôler l'erreur de remplissage de chaque bouteille de liquide à l'intérieur 1%, répondant ainsi aux besoins du haut débit, à grande échelle, et production de précision. En même temps, l'équipement est de qualité alimentaire 304 acier inoxydable, qui est conforme aux normes sanitaires internationales, et est non seulement stable en fonctionnement mais également pratique en maintenance, ce qui le rend très adapté à l'industrie moderne de l'emballage de liquides.

Spécifications de la ligne de production de remplissage de liquide

| Produits | Démêleur de bouteilles | Machine de remplissage | Machine de capsulage | Machine à étiqueter |

| Tension | 220v | |||

| Pouvoir | 120w | 500w | 0.8kW | 1.5kW |

| Rendement | / | 5-60 bouteilles/min | 30-60 pièces/min | 20-200 pièces/min |

| Poids | 120kilos | 800kilos | 550kilos | 270kilos |

| Taille(mm) | 1250*1250*1350 | 2000*1250*1600 | 2000*850*1800 | 1220*1250*1470 |

| Diamètre de la bouteille | / | / | ∅35-∅140mm | ∅30-∅180mm |

| Hauteur de l'étiquette | / | / | / | 15-150mm |

| Longueur de l'étiquette | / | / | / | 25-300mm |

| Diamètre du bouchon de la bouteille | / | / | 20-100mm | / |

Applications industrielles de la chaîne de production de remplissage de liquides

Cette ligne de production de remplissage est particulièrement adaptée au conditionnement de divers produits liquides, couvrant un large éventail d'industries, y compris, mais sans s'y limiter:

Performance exceptionnelle de la ligne de production de liquides

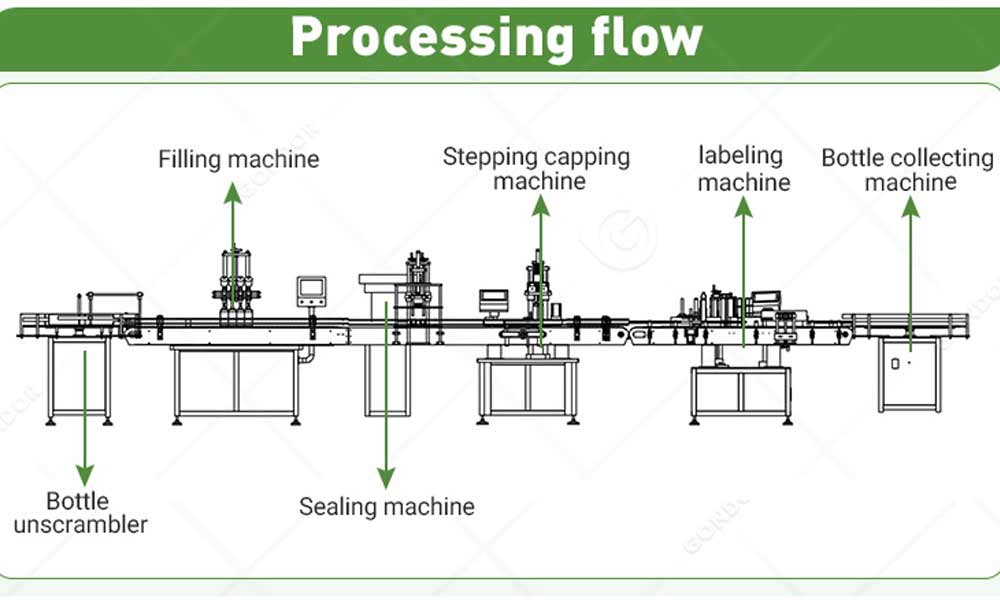

Flux de travail de la ligne de remplissage de liquide

Les machines de remplissage de liquides sont basées sur un contrôle zoné et un suivi synchrone. La ligne de production est planifiée de manière centralisée par un automate. Des capteurs à chaque station (photo-électrique, détecteurs de proximité, etc.) détecter la position du conteneur et renvoyer les signaux au système de contrôle, qui dirige alors les mécanismes correspondants (tels que les têtes de remplissage et les têtes de bouchage) pour effectuer des actions précises au moment du mouvement ou de l'immobilité.

Un flux de travail typique est le suivant (prendre les bouteilles de boisson comme exemple):

Fourniture de bouteilles vides: Bouteilles vides, après avoir été dépalettisé ou sorti de la machine de soufflage amont, sont introduits dans la chaîne de production en un seul, colonne uniformément espacée par une bande transporteuse.

Nettoyage des bouteilles vides (si nécessaire): Les bouteilles sont rincées avec de l'air purifié ou de l'eau stérile dans une station de rinçage inversée avec le goulot de la bouteille vers le bas..

Alignement et remplissage: Le tapis roulant achemine les bouteilles vers la table rotative ou la station de remplissage linéaire de la remplisseuse, où le goulot de la bouteille est positionné avec précision sous la valve de remplissage.

Scellement immédiat: Les bouteilles remplies sont immédiatement envoyées à l'unité de scellage, où la tête de bouchage saisit le capuchon et le serre, ou une capsuleuse appuie sur le capuchon couronne.

Scellage et étiquetage secondaires: Cela peut impliquer un scellement avec une feuille d'aluminium, scellage par film thermorétractable, etc.. Le produit entre ensuite dans l'étiqueteuse pour l'apposition précise de l'étiquette principale.

Inspection et marquage en ligne: Une trieuse pondérale élimine les produits dont le volume de remplissage est insuffisant; un système d'inspection par vision vérifie le niveau du liquide, scellage, et la qualité de l'étiquetage; une imprimante à jet d'encre imprime la date de production et le numéro de lot sur la bouteille ou l'étiquette.

Sortie du produit fini: Les produits qualifiés sont collectés par un tapis roulant et automatiquement emballés dans des cartons ou des caisses par un encaisseur.. Enfin, ils peuvent être empilés en piles palettisées par un robot de palettisation, en attente d'entreposage.

Recommandation d'équipement correspondant

Pour construire un système plus efficace, atelier d'emballage entièrement automatique, vous pouvez également envisager d'utiliser le matériel suivant:

- Scelleuse de cartons

- Imprimante à jet d'encre

- Machine de tunnel thermorétractable

- Système de convoyeur