Vous voulez posséder facilement du croustillant, doux, et des produits à base de fil de viande de couleur dorée? Gondor machine à fil de viande apporte un nouveau choix d'intelligence, efficace, et une production standardisée pour les transformateurs alimentaires du monde entier! Cet équipement est un équipement automatique spécialement développé pour la production de fil à viande. Grâce à un chauffage précis, en remuant, et systèmes de contrôle de la température, les matières premières carnées sont rapidement déshydratées, les fibres sont cassées et entièrement assaisonnées, et enfin, l'amende, lâche, et de délicieux produits à base de fil de viande sont fabriqués.

| Modèle |

Tension |

Pouvoir |

Capacité |

Volume total |

Diamètre*Profondeur |

Taille |

Poids |

| GD-FMFM-A430 |

220V |

2.2KW |

4-6kg/heure |

30L |

430*250mm |

520*480*830mm |

65kilos |

| GD-FMFM-A600 |

380V |

0.75KW |

10-12kg/heure |

84L |

600*280mm |

720*630*1000mm |

130kilos |

| GD-FMFM-A800 |

380V |

0.75KW |

20-25kg/heure |

150L |

800*280mm |

950*850*1000mm |

320kilos |

| GD-FMFM-B500 |

380V |

1.5KW |

20kg/heure |

130L |

500*660mm |

1490*1100*1545mm |

280kilos |

| GD-FMFM-B700 |

380V |

2KW |

35kg/heure |

360L |

700*900mm |

1660*1360*1750mm |

350kilos |

| GD-FMFM-B900 |

380V |

2KW |

60kg/heure |

640L |

900*1000mm |

1860*1510*1900mm |

450kilos |

La machine à fil de viande Gondor répond aux divers besoins du marché mondial

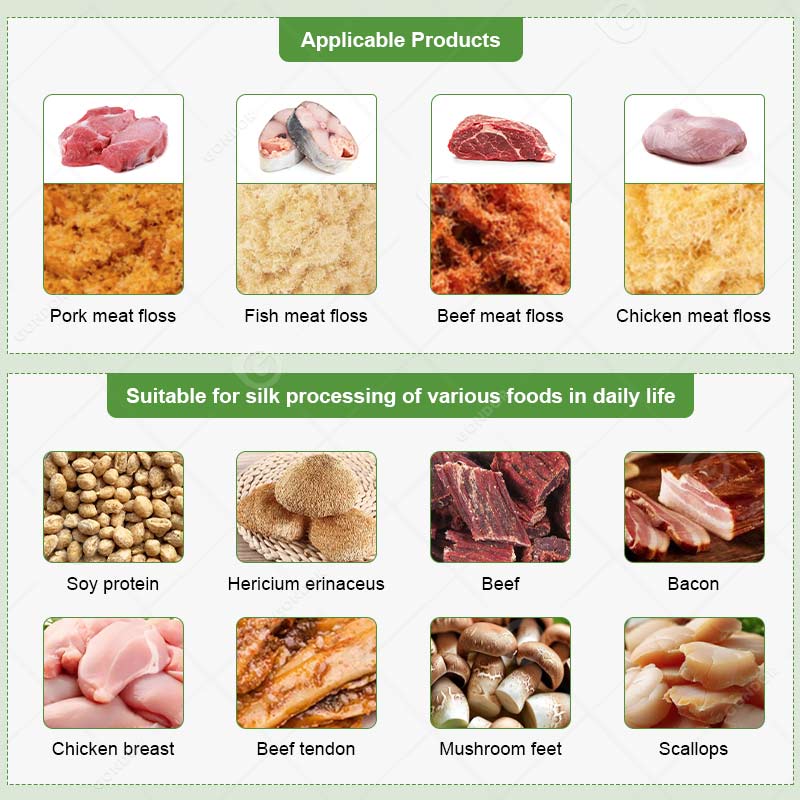

La machine à fil de porc ne se limite pas seulement à la production traditionnelle de fil de porc, mais convient également à la fabrication d'une variété de produits:

- Fil De Porc

- Fil de poisson

- Fil de poulet

- Fil dentaire pour enfants

- Fil de viande croustillant

- Fil de viande râpé

Cet équipement est largement utilisé dans la production industrielle par lots des usines de transformation des aliments., la cuisine centrale des industries de restauration ou de boulangerie, la friture fraîche sur place des magasins de produits alimentaires prêts à l'emploi et prêts à vendre, et le fil à viande sain haut de gamme fait maison sans additifs. En outre, dans le domaine du développement d'aliments fonctionnels, il montre également un grand potentiel pour répondre aux divers besoins de clients de différentes tailles en matière de qualité, capacité, et goût personnalisé de fil de viande séché.

Excellents avantages de performance de la machine à fil de porc

Agitation uniforme

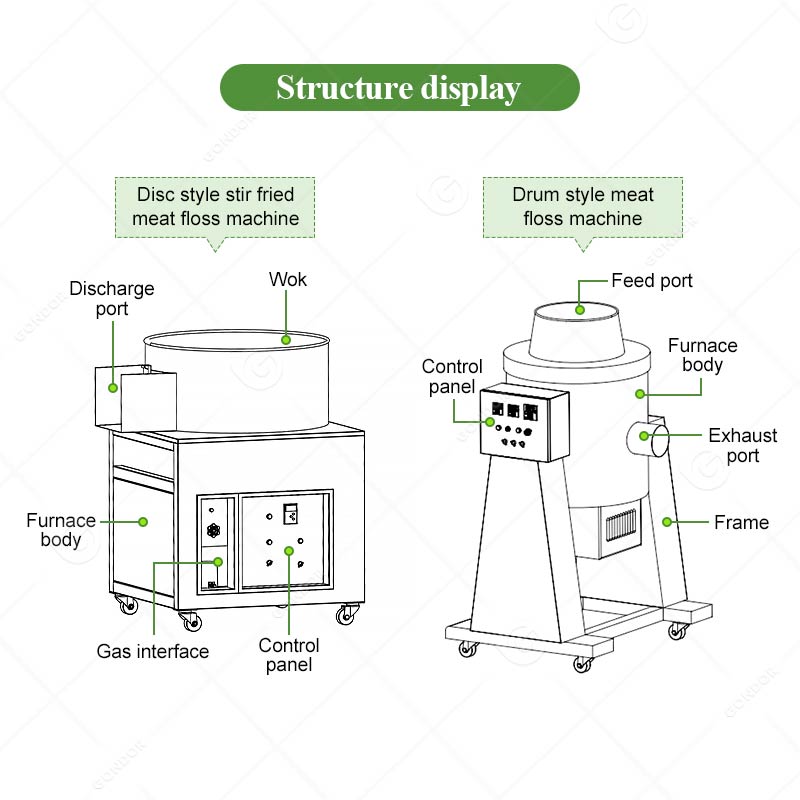

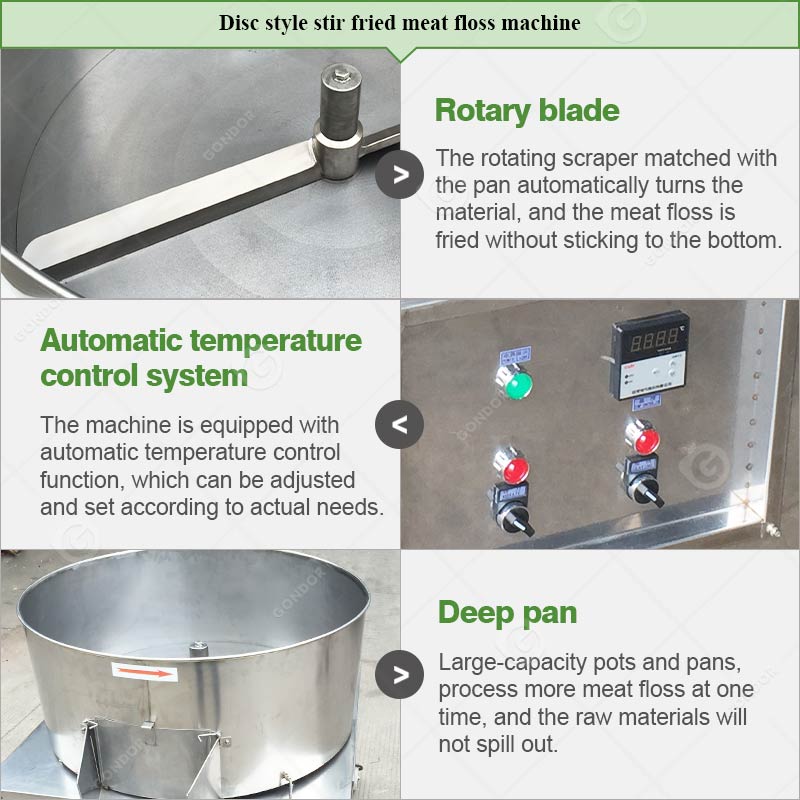

Equipé d'un grattoir rotatif ou d'une structure d'agitation en spirale à tambour, il simule complètement l'action de sauté manuel pour garantir que le fil de viande est sauté uniformément, duveteux, et pas cuit.

Contrôle précis de la température

Utilisation d'un système de double sonde de détection de température, la précision du contrôle de la température atteint ± 2 °C, et la température et la durée de friture peuvent être réglées librement pour garantir une couleur constante et une qualité stable de chaque pot de fil de porc..

Allumage automatique et flamme réglable

La technologie avancée d'allumage électronique rend la machine plus facile et plus sûre à utiliser, et la puissance de feu peut être ajustée à tout moment pour répondre aux exigences technologiques des différentes matières premières.

Haute capacité et rendement efficace

Le wok rotatif et le wok à tambour sont conçus avec une structure de wok profond ou de tambour de grande capacité, qui peut traiter plus de nourriture à la fois, gagner du temps et améliorer l’efficacité.

Applications polyvalentes

Il ne convient pas seulement à la friture de fil de viande, mais aussi pour faire frire le riz, nouilles frites, noix frites, flocons d'avoine frits et autres poitrines de bœuf frites ou braisées, pieds de cochon, porc braisé et sauce à la viande, ce qui enrichit grandement la gamme de produits.

304 Matériau en acier inoxydable

L'ensemble de la machine est de haute qualité 304 acier inoxydable, résistant aux températures élevées et facile à nettoyer, garantir la sécurité alimentaire et respecter les normes internationales d’hygiène.

Système de décharge automatique

L'équipement à tambour dispose d'un système de levage électrique et de déchargement automatique, ce qui permet d'économiser du travail et est efficace, et est particulièrement adapté aux lignes de production de masse.

Dites adieu au travail manuel et adoptez l’intelligence

Par rapport à la friture manuelle traditionnelle, la machine de fabrication de fil de viande améliore considérablement l'efficacité de la production, réduit les coûts de main d’œuvre, et garantit une qualité de produit stable. C'est un choix idéal pour les usines alimentaires modernes et les cuisines centrales.. Nous fournissons également une variété de machines de transformation des aliments, comme le machine d'assaisonnement à rouleaux, séchoir à bande continue, et machine d'emballage, pour vous aider à construire une ligne de production efficace et complète et à développer le marché mondial. Bienvenue à nous contacter pour plus d'informations sur les produits et des solutions personnalisées, et avancez ensemble vers un nouvel avenir de transformation intelligente des aliments!

Contactez-nous maintenant