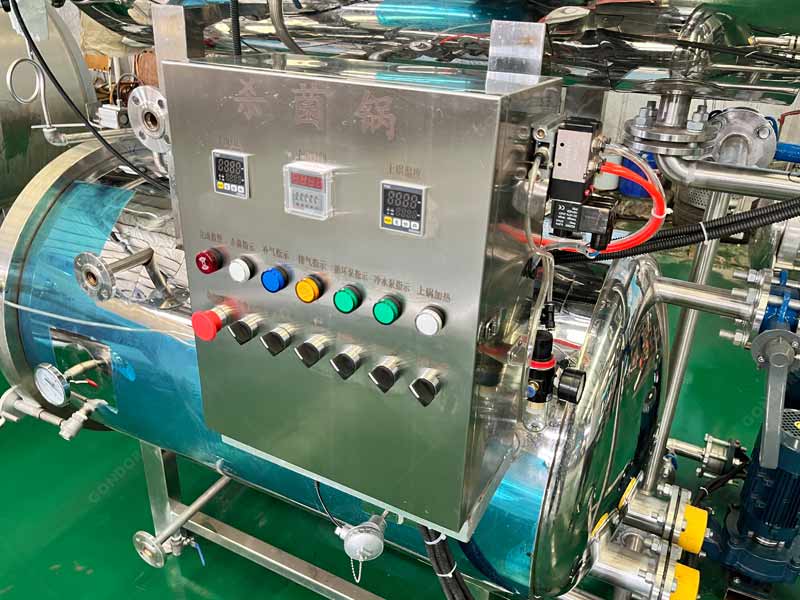

Dans les industries agroalimentaires et pharmaceutiques, la sécurité et la durée de conservation des produits sont d'une importance vitale. Avec ses puissantes performances de stérilisation à haute température et haute pression, le machine à cornue est devenu un choix idéal pour les entreprises de production alimentaire, sociétés pharmaceutiques, et laboratoires. Cet équipement adopte un contrôle intelligent et une conception à haute efficacité et économie d'énergie pour garantir que le processus de stérilisation est uniforme et approfondi et maximise la qualité du produit..

|

Modèle |

SL-1000 | SL-1200 | SL-1300 | |

| Longueur du cylindre(mm) | 2200 | 2700 | 4000 |

4000 |

|

Longueur totale(mm) |

4000 | 4500 | 5400 | 5800 |

| Largeur totale(mm) | 1550 | 1750 | 1750 |

1850 |

|

Hauteur totale(mm) |

2850 | 3100 | 3100 | 3300 |

| Capacité(kilos) | 500 | 800 | 1100 |

1500 |

|

Épaisseur du corps du pot(mm) |

4 | 5 | 5 | 4 |

| Puissance installée(kW) | 10 | 15.5 | 18.5 |

18.5 |

|

Consommation de gaz(kg/lot) |

460 | 570 | 610 | 730 |

| Consommation d'énergie(kW/h) | 7 | 14 | 14 |

16 |

|

Presse de conception(Mpa) |

0.35 | 0.35 | 0.35 | 0.35 |

|

Température de conception(°C) |

147 | 147 | 147 |

147 |

Domaines d'application du stérilisateur de cornue

Les stérilisateurs à cornue sont largement utilisés pour la stérilisation de divers matériaux d'emballage résistants aux hautes températures, et conviennent aux industries et produits suivants:

- Produits à base de viande: Viande pour le déjeuner, jambon, pattes de poulet, viande de boeuf séchée, etc..

- Produits à base de haricots: Tofu séché, produits végétariens, je suis du lait, etc..

- Produits de la mer: Poisson en conserve, produits à base de crustacés, etc..

- Produits végétaux: Légumes sauvages, maïs, champignons enoki en conserve, etc..

- Boîtes métalliques: Boîtes de conserve en fer blanc, canettes en aluminium, poisson en conserve, etc..

- Bouteilles en verre (non recommandé, mais des solutions spécifiques peuvent être personnalisées)

- Sacs en aluminium

- Sacs sous vide résistants aux hautes températures

- Sacs de cuisson haute température

- Lait de coco, je suis du lait

- Jus, boissons pour sportifs

- Stérilisation des déchets médicaux

- Stérilisation des milieux de culture de champignons comestibles

- Stérilisation du bois et du sol

Les principaux avantages de la machine de traitement des cornues

Contactez-nous pour découvrir plus d’équipements de transformation des aliments

En plus de la cornue, nous fournissons également des équipements avancés tels que machines sous vide à double chambre, machines de remplissage de liquides, machines de nettoyage de fruits et légumes, etc.. pour vous aider à moderniser votre ligne de production! Contactez-nous pour plus de détails sur le produit, notre équipe vous fournira les solutions de stérilisation les plus professionnelles!