Ligne de production de frites semi-automatiques Gondor

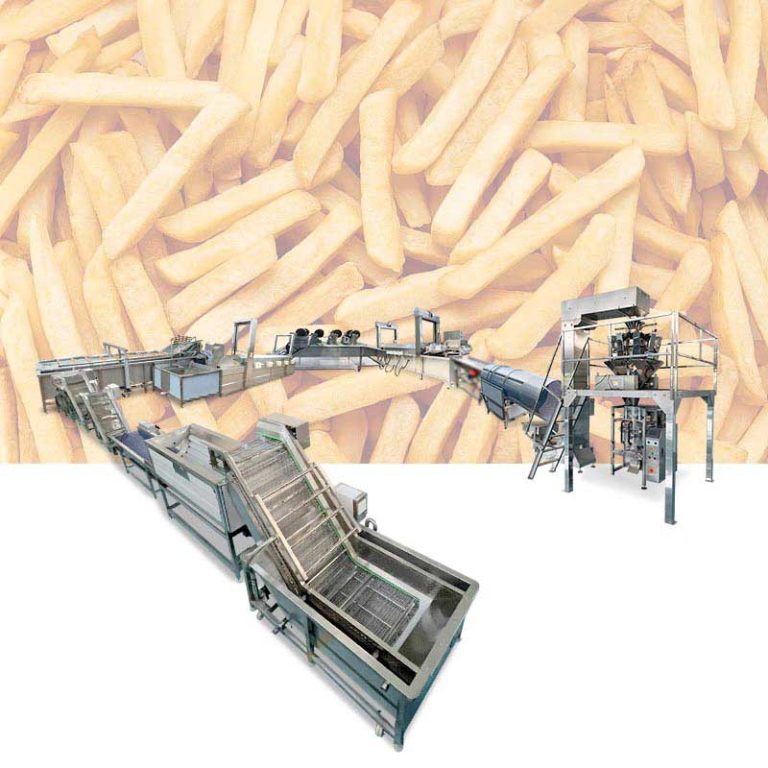

Notre ligne de production de frites semi-automatique assure une production efficace et standardisée, qualité stable, et un fonctionnement économe en énergie. Acier inoxydable, durable, étanche, conforme aux normes d'hygiène alimentaire. L'équipement couvre l'ensemble du processus, depuis les pommes de terre crues jusqu'à l'emballage., qui réalise une production automatique et aide les entreprises à maintenir leur compétitivité.

Composants de la ligne de production de frites semi-automatique

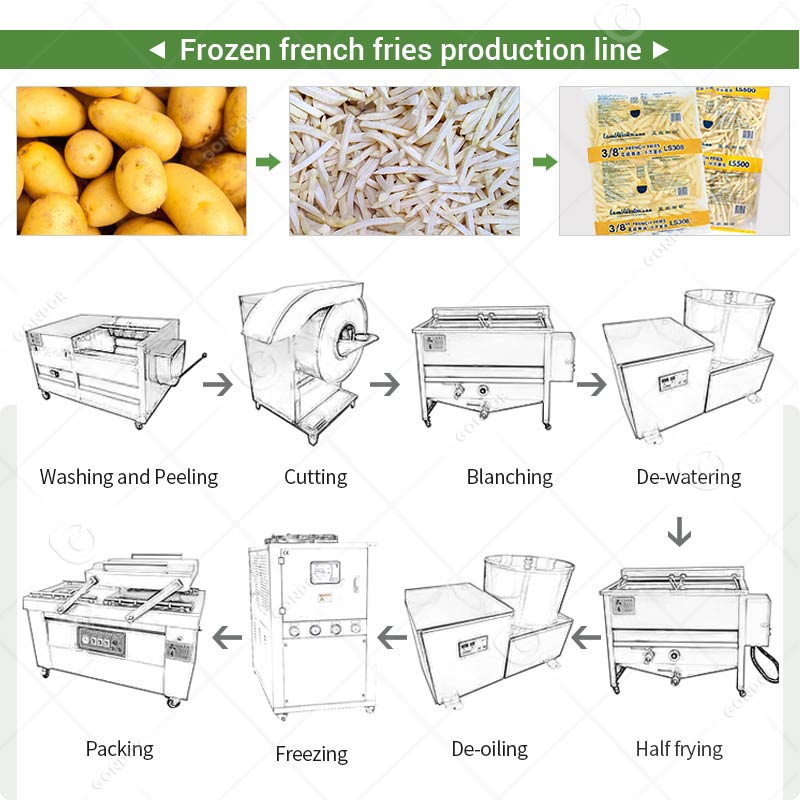

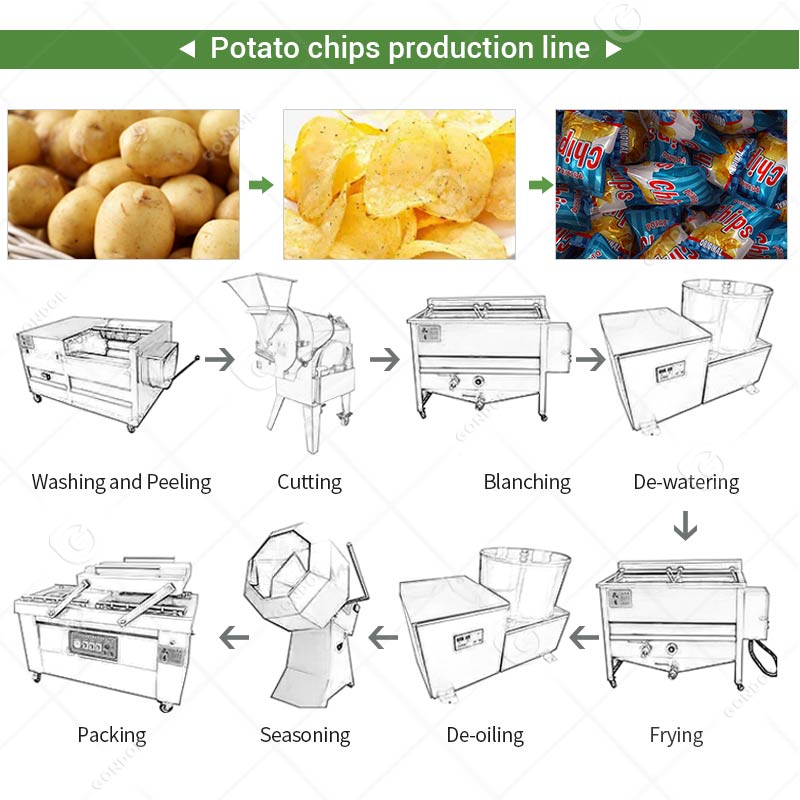

Une ligne de traitement de frites semi-automatique fait référence à un système de traitement de frites dans lequel, tandis que les machines individuelles clés (lavage, peeling, coupe, friture, etc.) sont automatisés, certains processus (comme l'alimentation, transfert, chargement/déchargement surgélation, conditionnement, etc.) nécessite toujours une assistance manuelle.

Les machines courantes de la chaîne de production sont les suivantes:

- Fonction: Cette machine lave soigneusement les pommes de terre crues, enlever la peau, saleté, impuretés, et couche externe, améliorer les normes d'hygiène pour la transformation ultérieure et les préparer à la découpe et à la friture.

- Caractéristiques: Utilise de l'acier inoxydable de qualité alimentaire, une conception combinant un débit d'eau aéré et des brosses à rouleau pour un nettoyage en profondeur et un taux de pelage élevé; construction compacte, facile à nettoyer, réduisant le temps de prétraitement manuel.

- Fonction: Coupe les pommes de terre lavées en lanières ou en tranches uniformes, assurant un chauffage uniforme des frites ou des chips lors du traitement ultérieur, résultant en une texture cohérente dans le produit fini.

- Caractéristiques: Lames remplaçables, épaisseur réglable; coupe lisse sans endommager la texture, adaptable à différentes spécifications de produits (par ex., croustilles fines ou frites longues).

- Fonction: Chauffe rapidement les frites/tranches de pommes de terre coupées avec de l'eau chaude ou de la vapeur pour éliminer l'excès d'amidon., inhiber l'activité enzymatique, améliorer la couleur et la texture du produit fini, et réduire la casse lors de la friture.

- Caractéristiques: La température et le temps réglables aident à maintenir la couleur naturelle du produit et à améliorer la texture croustillante après la friture.

- Fonction: Élimine l'excès d'humidité de la surface des frites/tranches de pommes de terre blanchies par centrifugation ou vibration, réduisant l'humidité pendant l'étape de friture et améliorant l'efficacité de la friture.

- Caractéristiques: Déshydratation très efficace, opération simple, réduit les éclaboussures d'huile et d'eau pendant la friture, améliorer la sécurité et la stabilité de la production.

- Fonction: Faire frire des frites/chips de pommes de terre déshydratées dans de l'huile chaude jusqu'à ce qu'elles soient bien cuites et croustillantes à l'extérieur.. Il s’agit du processus essentiel pour obtenir la texture et la saveur finales..

- Caractéristiques: Température d'huile contrôlable, circulation d'huile uniforme pour un brunissement rapide et uniforme; options de chauffage électrique ou au gaz disponibles.

- Fonction: Place les chips/frites frites dans la machine à déshuiler, où la centrifugation ou la vibration élimine l'excès d'huile de surface, réduire la teneur en huile du produit fini et améliorer le goût et la santé.

- Caractéristiques: Haute efficacité de déshuilage, opération facile, contribue à prolonger la durée de conservation des produits et améliore l'expérience du consommateur.

- Fonction: Saupoudrer uniformément les assaisonnements sur le produit déshuilé, conférer différentes saveurs et rendre le produit fini plus attrayant pour le marché.

- Caractéristiques: Assaisonnement uniforme, vitesse et types d'assaisonnements réglables pour répondre à diverses exigences de saveur personnalisées.

- Fonction: Pèse et emballe automatiquement les croustilles/frites assaisonnées pour un stockage facile, ventes, et transport.

- Caractéristiques: Permet le pesage automatique, emballage rempli de gaz ou sous vide, et l'étanchéité, améliorant considérablement la vitesse d'emballage et les normes d'hygiène.

Spécifications de la ligne de production de frites semi-automatique

| Nom de l'appareil | Pouvoir(kW) | Dimensions(mm) |

| Machine de nettoyage et d'épluchage | 1.5 | 1750x900x900 |

| Machine à couper les pommes de terre | 0.75 | 850x850x1000 |

| Machine à blanchir | 24 | 1400X600X1050 |

| Machine à déshydrater les pommes de terre | 0.75 | 850x500x600 |

| Machine à frire les frites | 24 | 1400X600X1050 |

| Machine de déshuilage de copeaux | 0.75 | 850X500X600 |

| Machine à assaisonner | 1.1 | 1400X900X1700 |

| Machine d'emballage | 1.5 | 800X500x100 |

Industries adaptées à la chaîne de production semi-automatique de frites

La ligne de production convient à toutes sortes d’industries agroalimentaires, et les petits entrepreneurs comme les grands fabricants de produits alimentaires peuvent en bénéficier.

Coupe efficace, friture, et assaisonnement pour garantir un goût croustillant et une apparence uniforme des chips.

Coupe précise, contrôle de l'eau, et la congélation rapide peut améliorer la qualité des frites surgelées, qui convient à la chaîne d'approvisionnement mondiale.

Fournir une modulation diversifiée des saveurs et un emballage automatique pour aider les entreprises de snacks à produire à grande échelle.

Produire efficacement des frites standardisées, répondre aux besoins d'approvisionnement rapide des chaînes de restauration rapide, et assurent un goût stable.

Automatisez l'emballage et le contrôle qualité pour garantir que les produits répondent aux normes du marché et conviennent aux ventes en supermarché..

Que vous souhaitiez élargir le marché existant ou créer une toute nouvelle entreprise de frites, cette ligne de production peut fournir des solutions stables et efficaces.

Avantages considérables de la chaîne de production Frozen French Friends

Plus de recommandations d’équipements connexes

En complément de la ligne de production semi-automatique de frites, nous fournissons également d'autres équipements de transformation des aliments, tel que:

- Ligne de production de chips de pomme de terre entièrement automatique – Convient aux entreprises de production alimentaire à grande échelle.

Bienvenue à nous contacter pour obtenir des solutions personnalisées et des informations de devis pour développer votre entreprise de transformation des aliments en montant un escalier.!