Lignes de production de pâtes Gondor

À l’ère actuelle de recherche de qualité et de consommation personnalisée, les petits ateliers alimentaires et les entrepreneurs sont constamment à la recherche d'équipements de production capables d'équilibrer la technologie, efficacité, et goûter. Notre tout nouveau petite ligne de production de pâtes est né dans ce but. Il combine la technologie traditionnelle italienne de fabrication de nouilles avec une technologie d'automatisation moderne., ce qui permet à votre atelier de reproduire facilement la saveur italienne authentique et de créer une marque alimentaire locale compétitive.

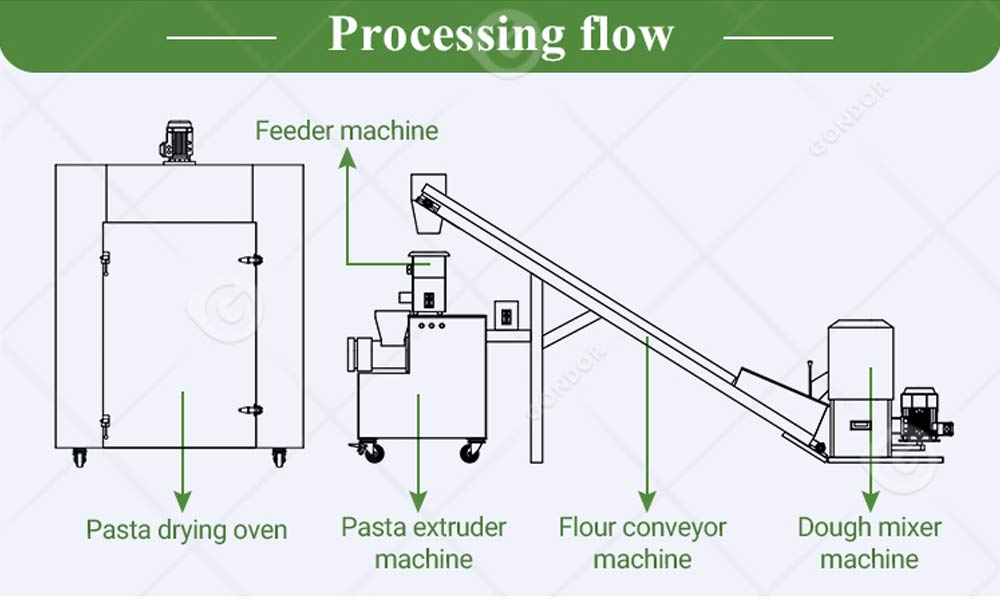

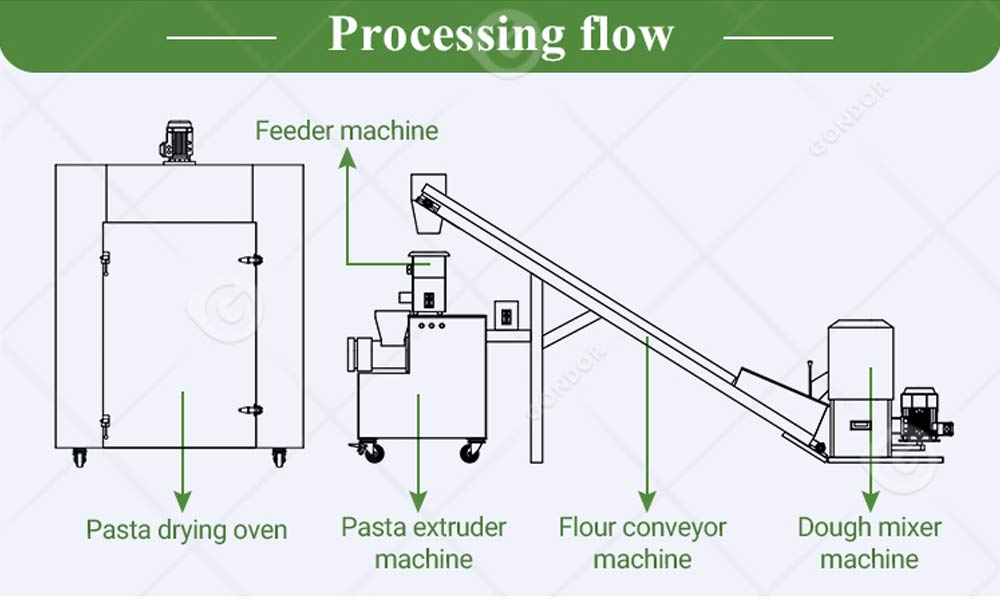

Cette ligne de production de macaronis semi-automatique est spécialement conçue pour les petites et moyennes entreprises alimentaires, cuisines centrales, et ateliers de démarrage. L'ensemble de la ligne est constitué d'un pétrin, convoyeur de farine, système d'alimentation, extrudeuse de macaronis, et machine à sécher. L'équipement présente une structure compacte, faible encombrement, et opération facile, prenant en charge divers moules et capacités de production personnalisables pour réaliser une production entièrement automatisée, des matières premières aux produits finis.

Spécifications de la ligne de production de petites pâtes

| Nom de l'appareil |

Tension |

Pouvoir |

Matériel |

Taille |

| Machine à pétrir la pâte |

380V |

3kW |

Acier inoxydable |

900*550*1000mm |

| Convoyeur de farine |

220V |

0.35kW |

2800*750*650mm |

| Extrudeuse de pâtes |

380V |

5.5kW |

1100*650*1200mm |

| Étuve à pâtes |

380V |

12kW |

1400*1250:2350mm |

| Machine d'alimentation |

220V |

0.3kW |

650*420*450mm |

Marché cible de la ligne de production de pâtes longues

La ligne de production de pâtes longues est un choix idéal pour les petites et moyennes entreprises agroalimentaires du monde entier., spécialement pour les groupes de clients suivants:

Aider les marques à différencier leur saveur italienne sur le marché local.

Ateliers culinaires pour startups

Un schéma d'équipement idéal avec un faible investissement et un retour sur investissement élevé.

Producteurs d'aliments de spécialité

Utilisé pour développer des pâtes courtes aux formes et aux saveurs innovantes.

Restauration & Restaurants

Répondre à la demande de fabrication de nouilles fraîches sur place et améliorer l'expérience client.

Sous la tendance croissante des consommateurs’ poursuite de la santé, texture faite à la main, et un goût frais, cette petite ligne de production aidera les entreprises à saisir les opportunités du marché.

Caractéristiques de l'équipement de base de la ligne de production de pâtes courtes

Mélangeur de pâte

La structure en acier inoxydable est adoptée, et le temps et la vitesse d'agitation peuvent être réglés librement pour garantir que la pâte est uniforme et élastique.. Equipé d'une fenêtre visuelle et d'un système de protection automatique de sécurité, la sécurité et la qualité sont prises en compte.

Convoyeur de farine

Le système de transport entièrement fermé évite la pollution secondaire, et la longueur de transport peut être personnalisée, réduisant efficacement le travail de manutention manuelle. Économie d'énergie, efficace, continu, et stable.

Alimentateur de précision

- La conception d'alimentation en spirale réalise une alimentation quantitative de haute précision et garantit un processus d'extrusion stable et fluide.

- La commande indépendante du moteur peut ajuster de manière flexible la vitesse d'alimentation en fonction des différentes caractéristiques de la pâte.

Extrudeuse de macaronis

- L'équipement de base de toute la ligne peut être une extrudeuse à une ou deux têtes..

- Une variété de pâtes courtes peut être facilement produite en changeant de moule, y compris les macaronis, Penne, Fusillis, papillon, Coquilles, et ainsi de suite.

- La tête de la machine est équipée d'un coupeur rotatif, qui peut ajuster automatiquement la longueur et la vitesse de coupe pour obtenir une coupe précise, pleine forme, et surface lisse.

Machine de séchage

- Un système de circulation d'air multicouche peut contrôler la température, humidité, et débit d'air indépendamment.

- Réaliser le processus de séchage lent à basse température, conserver au maximum la structure interne et le goût des pâtes, et éviter les fissures et les déformations.

- Les macaronis séchés peuvent être directement emballés ou soumis au processus de refroidissement ultérieur..

Avantages uniques d'une petite ligne de production de pâtes

Conception modulaireCapacité personnalisableOptions multi-moulesFormage rapide & Sortie stableAssistance professionnelle:

Il peut être étendu de manière flexible en fonction des exigences de production.

De 50kg/h à 300kg/h, adapté à une production à différentes échelles.

Soutenir le développement de formes personnalisées pour répondre aux besoins des produits créatifs.

Haute efficacité et haute cohérence.

Assurer l'installation et le débogage, formation de formule, et service après-vente.

Aide à créer une saveur italienne authentique

Si vous prévoyez un projet complet de transformation de pâtes, nous fournissons également une variété d'équipements de soutien:

Bienvenue à nous contacter pour une solution complète et un devis. Laissez la petite ligne de production de macaronis être la première étape pour créer une saveur italienne authentique et élargir le marché mondial.!

Contactez-nous maintenant