Gondor Vacuum Frying Machine Introduction

Vacuum frying machine is an advanced food processing system that utilizes low-temperature vacuum technology to produce high-quality fried snacks. Operated via an intuitive touchscreen interface with automated PLC control, it maintains precise temperature (80-120°C) and pressure conditions throughout the frying process.

This innovative equipment significantly reduces oil absorption by 30-50% while preserving natural colors, saveurs, and nutrients often lost in conventional frying. Ideal for producing premium fried fruits, légumes, and specialty snacks with enhanced nutritional value and superior sensory characteristics.

Gondor High-Performance Vacuum Frying Machine

As a factory specializing in the food machinery field, we deeply understand the core demands of businesses when selecting equipment—not only to secure the best vacuum frying machine but also to balance the rationality of the vacuum frying machine price, and more importantly, to ensure the equipment meets the high-intensity usage requirements of commercial scenarios.

Our carefully selected commercial vacuum frying machine series are all made of 304 stainless steel with a stable vacuum system, enabling precise control of the low-temperature processing environment at 80-120℃. Suitable for processing various ingredients such as fruits, légumes, and meats, these machines come at a reasonable price and can meet the different production capacity needs of businesses ranging from start-up stores to large-scale food factories.

Gondor Vacuum Frying Machine Models

Our factory offers various models of vacuum frying machines, along with a one-year warranty and comprehensive after-sales service, ensuring you can not only choose high-quality equipment with superior performance but also enjoy an affordable purchasing experience.

| Modèle | Experimental Model | GD-VFFM-50 | GD-VFFM-1100 | GD-VFFM-1200 | GD-VFFM-1300 |

| Quantity Of Frame Material | 2 | 2 | 2 | 2 | 2 |

| Work Vacancy Rate | -0.092~-0.098Mpa | -0.092~-0.098Mpa | -0.092~-0.098Mpa | -0.092~-0.098Mpa | -0.092~-0.098Mpa |

| Température de travail | 80~120℃ | 80~120℃ | 80~120℃ | 80~120℃ | 80~120℃ |

| Puissance de la pompe à vide | 5.5kW | 11kw/7.5kw | 11kW | 11+3kw/11kw | 15+4kw/15kw |

| Mode Of Heating | Electricity/Steam | Vapeur | |||

| Volume | 14L | 86L | 255L | 430L | 630L |

| Loading Material (French Fries) | 5-6kg/heure | 30-50kg/heure | 80-100kg/heure | 180-200kg/heure | 260-300kg/heure |

| Total Installed Power / Actual Power | 31kw/18.25kw | 21kw/14kw | 21kw/14kw | 25kw/18kw | 28kw/22kw |

| Dimension | 1600*2000*2000mm | 2300*2100*2600mm | 3000*3000*3090mm | 3400*3400*3230mm | 3930*3670*3720mm |

Gondor Vacuum Frying Machine Details

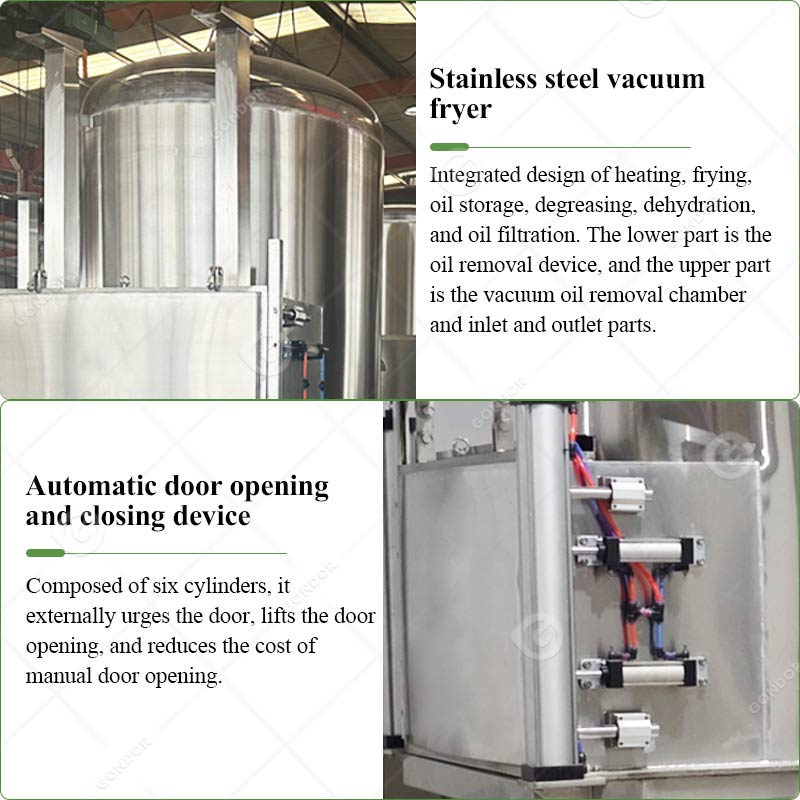

This stainless steel vacuum frying machine features an integrated design encompassing heating and frying processes. It includes an oil removal device at the bottom and a vacuum degreasing chamber and feeding/discharging components at the top. Its six-cylinder automatic door opening and closing device reduces labor costs.

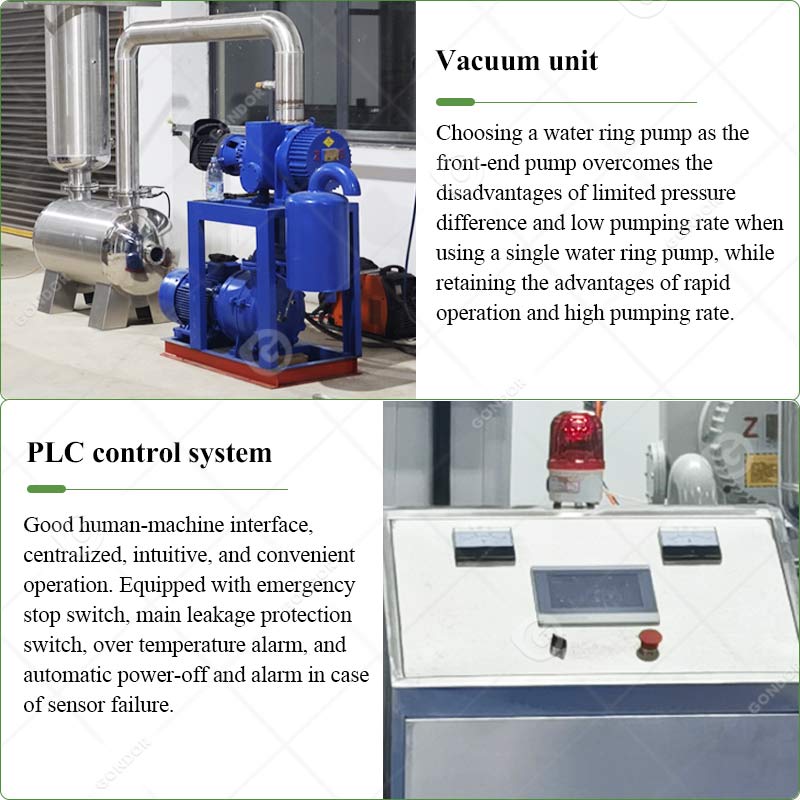

The vacuum system uses a water ring pump as the forestage pump, balancing high pumping speed with stable performance. The PLC control system not only boasts a user-friendly and intuitive interface but also features multiple safety devices such as emergency stop and leakage protection. Over-temperature alarms and automatic power-off in case of sensor malfunctions ensure safe operation.

Gondor Vacuum Frying Machine Application

The vacuum frying machine is suitable for food processing plants, fabricants de snacks, health food producers, restaurant central kitchens, agricultural product processing enterprises, and R&Laboratoires D.

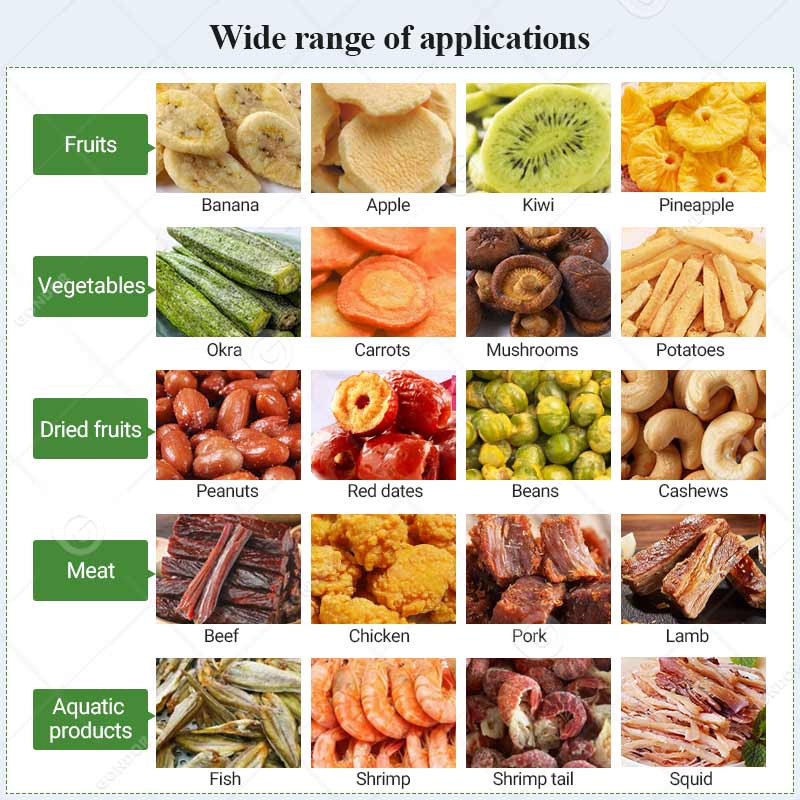

A vacuum frying machine can process various products, y compris les fruits (apple chips, banana chips, mango chips), légumes (carrot chips, pumpkin chips, chips), viandes (chicken chips, fish skins), noix (cacahuètes, amandes), and specialty snacks (crispy rice cakes, banana spring rolls). It supports both sweet and savory flavor profiles with oil content reduced by 30-50% compared to traditional frying.

Gondor Vacuum Frying Machine Features

Équipement de support recommandé

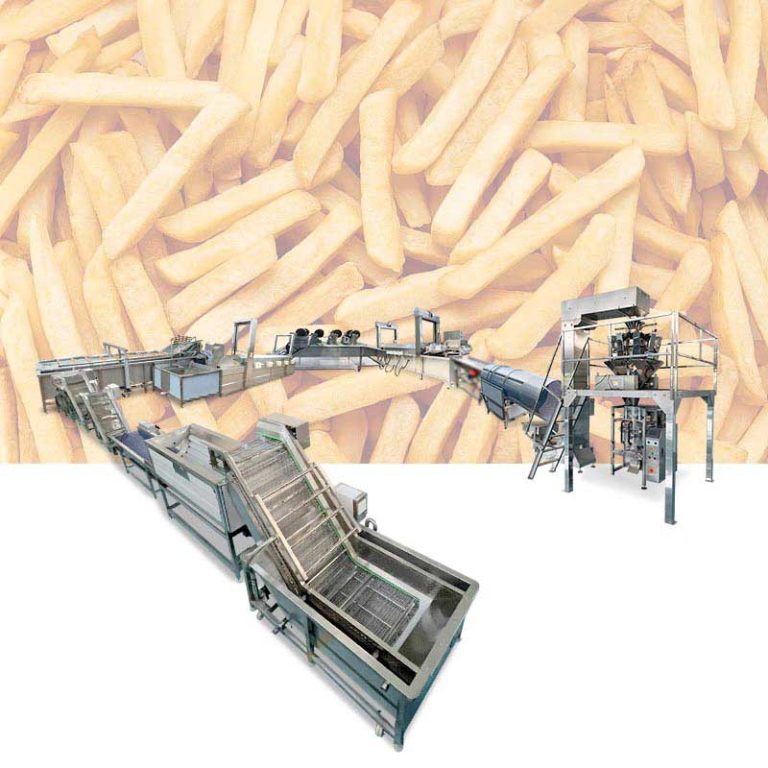

To create a more efficient integrated food frying solution, the following equipment can be used in conjunction:

- Bubble Cleaning Machine: Thoroughly washes away impurities from the surface of food, deeply cleaning while protecting the integrity of the ingredients, laying a solid hygienic foundation for frying.

- Withering Machine: Gentle sterilization preserves the nutrients and flavor of food, effectively extending product shelf life and meeting the safety handling needs of various foods.

- Machine de conditionnement d'oreillers: Automates metering, scellage, et coupe, producing aesthetically pleasing and secure packaging, facilitating standardized and large-scale packaging of fried foods.