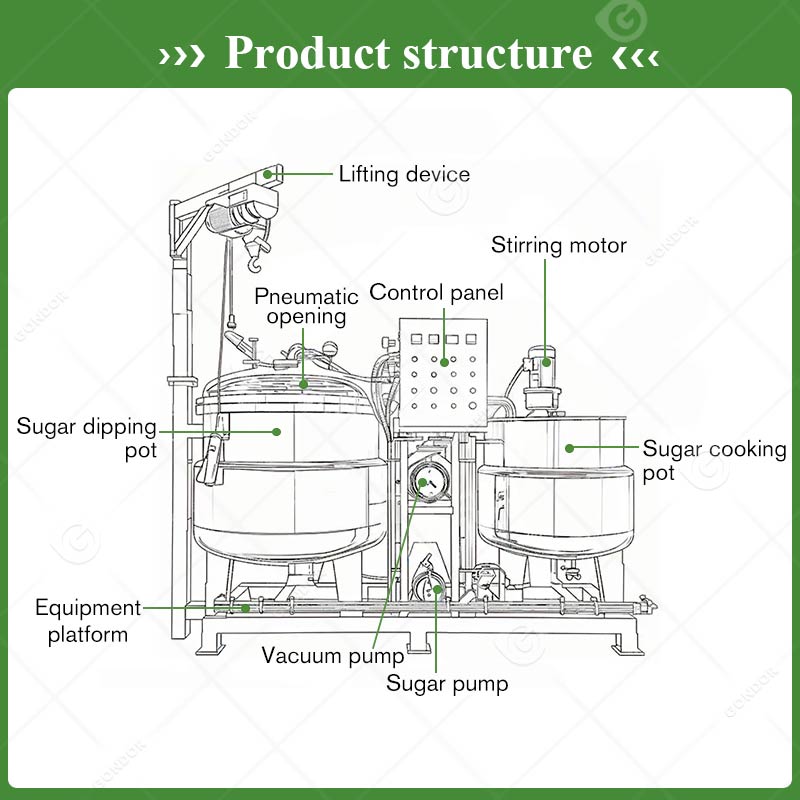

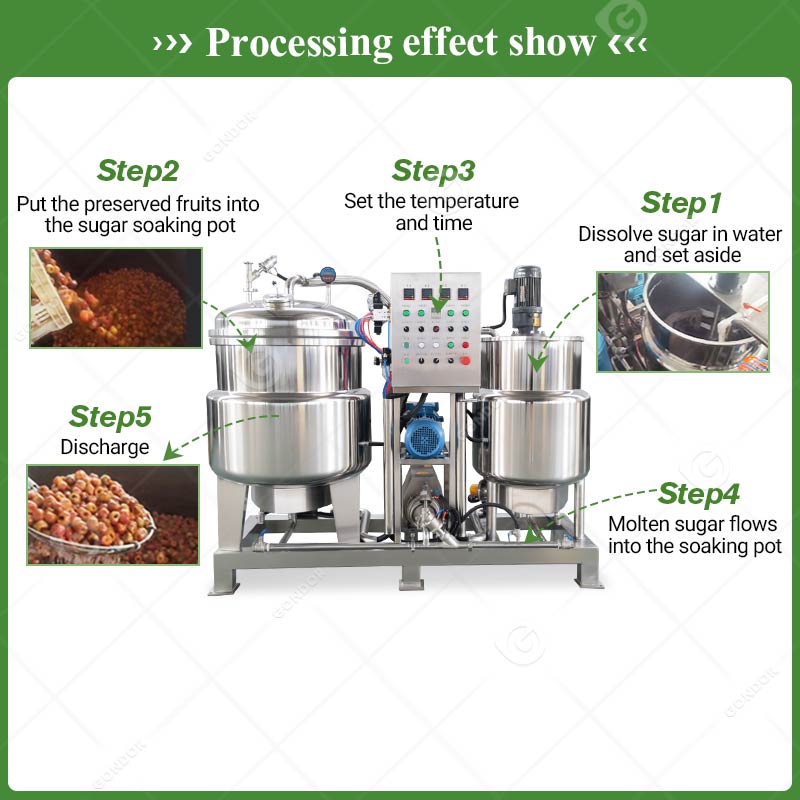

Le machine de trempage de sucre sous vide est un équipement efficace spécialement conçu pour la production de fruits en conserve, noix enrobées de sucre, et des produits de boulangerie sucrés. Il peut améliorer considérablement l'efficacité de la pénétration du sucre grâce à la technologie de pression sous vide., et la vitesse peut atteindre trois fois celle des méthodes traditionnelles, raccourcissant ainsi considérablement le cycle de production. En même temps, cette technologie peut mieux conserver la couleur naturelle, saveur, et composants nutritionnels des matières premières. L'ensemble de l'équipement est en acier inoxydable 304/316L de qualité alimentaire, qui est conforme aux normes d'hygiène internationales. Il est équipé d'un système de contrôle intelligent à écran tactile PLC, qui peut ajuster avec précision le degré de vide, température, et la pression, et réaliser toute l'opération automatique. Avec sa grande efficacité, large applicabilité, et structure solide, cet équipement est devenu un équipement indispensable dans l'industrie moderne de fabrication de bonbons et de conserves.

| Modèle | capacité | Tension | Pouvoir

(Pot à sucre/Pot à sucre/Pompe à vide) |

Diamètre du pot * profondeur * épaisseur(mm) | Dimensions(mm) | Poids | Mode de chauffage |

| 100L | 50kilos | 380V

50Hz |

18/18/2.35KW | 500*450*3 | 2000*720*1350 | 350kilos | Chauffage électrique/

chauffage à la vapeur |

| 200L | 100kilos | 24/24/2.35KW | 700*500*4 | 2200*1000*1450 | 400kilos | ||

| 300L | 150kilos | 24/24/4KW | 800*600*4 | 2450*1350*1550 | 500kilos | ||

| 400L | 200kilos | 24/24/4KW | 800*800*4 | 2450*1350*1750 | 700kilos | ||

| 500L | 250kilos | 24/24/4KW | 1000*630*4 | 2500*1430*1900 | 700kilos | ||

| 800L | 400kilos | 36/36/5.5KW | 1000*1000**4 | 2500*1430*2460 | 850kilos | ||

| 1000L | 500kilos | 48/48/5.5KW | 1200*890*5 | 2600*1650*2230 | 1100kilos |

Industries d'application de la machine de trempage de sucre sous vide

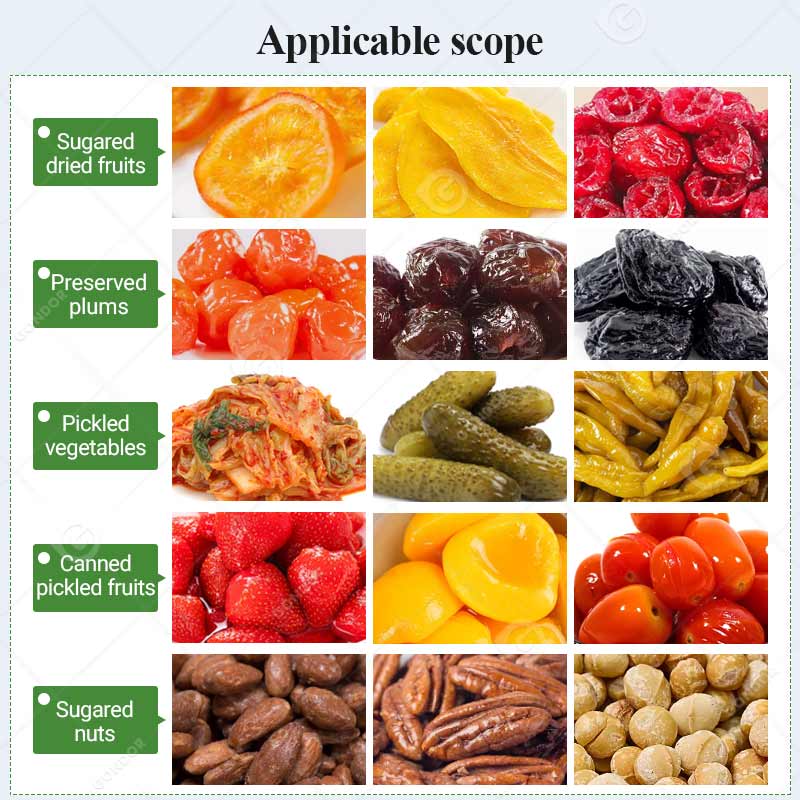

La machine de trempage du sucre sous vide est largement utilisée dans différents secteurs de l'industrie alimentaire:

- Usines de transformation des aliments – Production de fruits confits et de conserves à grande échelle.

- Fabricants de bonbons – Enrobage de sucre et imprégnation de sirop de bonbon.

- Producteurs de conserves de fruits – Transformation des fruits secs, fruits sucrés, et confitures.

- Usines de transformation de noix – Cacahuètes enrobées de sucre, amandes, noix de cajou, et autres noix de confiserie.

- Fournisseurs d'ingrédients de boulangerie – Préparation de matières premières sucrées de boulangerie.

- Installations de décapage – Utilisé pour mariner des légumes comme les concombres et autres produits fermentés.

Avantages fonctionnels de la machine d'imprégnation sous vide de fruits

Machines connexes qui pourraient vous intéresser

Pour répondre aux besoins de production complets de divers clients, nous offrons également les services suivants:

- Friteuse sous vide: En bonne santé, chips de fruits et légumes à faible teneur en huile.

- Bouilloire à vapeur à double enveloppe: Traitement des confitures, sauces, et bases de bonbons.

- Bouilloires à sucre: Spécialisé dans la préparation de sirops de sucre.

- Systèmes de refroidissement: Réduction rapide de la température pour préserver la texture et la saveur du produit.