Soos wêreldwye sjokoladeverbruik groei, the chocolate production industry increasingly demands high-quality, doeltreffend, and automated equipment. To meet this demand, chocolate equipment technology continues to innovate. As key equipment, die chocolate mould machine, digital chocolate tempering machine, and chocolate ball machine drive changes in chocolate production processes. This article will explore the latest developments in these three types of equipment and their important role in the industry.

Chocolate Mould Machine: Precise Shaping

Chocolate mold machines are crucial in chocolate production. Met tegnologiese vooruitgang, modern mold machines have been optimized in many aspects, produksiedoeltreffendheid en produkkwaliteit te verbeter. Hier is 'n paar sleutelkenmerke:

Chocolate Depositing Line

Digital Chocolate Tempering Machine: Presiese temperatuurbeheer

Temperature control is crucial to chocolate making. Traditional methods are prone to unevenness and fluctuations, affecting quality. Digital chocolate tempering machines effectively solve these problems through precise temperature control and high automation, improving the taste and production efficiency of chocolate. The following are the main advantages of digital chocolate tempering machines:

Through the digital control system, the temperature and temperature change curves are accurately adjusted to ensure the best quality of each batch of chocolate.

Equipped with an intelligent touch screen and PLC control system, it is easy to operate and improves the automation level of the production line.

Efficient temperature control reduces the waste of chocolate during processing and improves production efficiency.

It can ensure that the taste and texture of each batch of chocolate in large-scale production remain consistent.

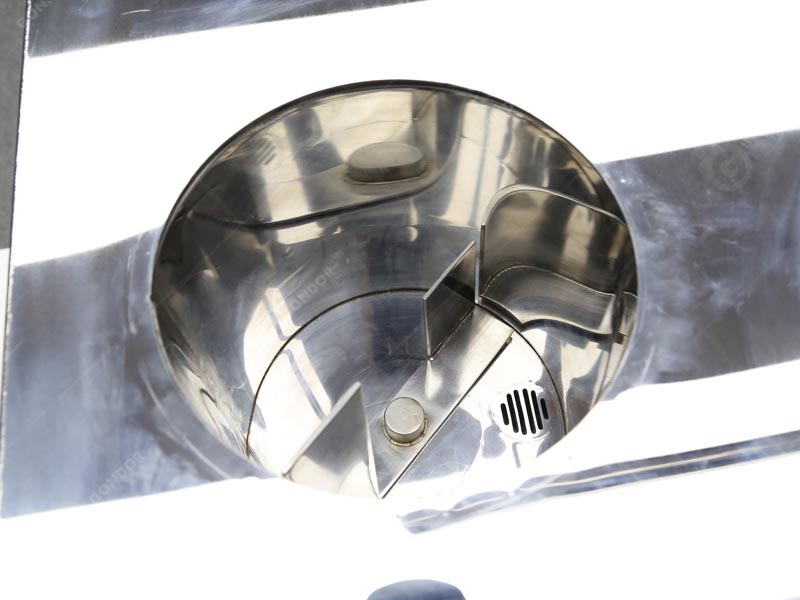

Chocolate Ball Machine: Create a Unique Chocolate Taste

The chocolate ball machine is a device that has attracted the attention of manufacturers in recent years. It is mainly used to make small chocolate products such as chocolate balls or chocolate beans through a rolling mechanism. It ensures the shape and taste of the chocolate balls are consistent and improves production efficiency. The following are the main features of the chocolate ball machine:

Industry Development Trend: Moving Towards Intelligence and Automation

As the requirements for chocolate quality and production efficiency increase, chocolate equipment is moving towards intelligence and automation. Many equipment manufacturers have introduced technologies such as artificial intelligence, the Internet of Things, and machine vision to improve the accuracy and stability of equipment. Byvoorbeeld, modern chocolate mold machines and tempering machines are equipped with intelligent fault diagnosis systems that monitor equipment status in real-time and automatically troubleshoot faults. Terselfdertyd, with the introduction of the “Industry 4.0” concept, chocolate production lines have been fully automated, greatly improving production efficiency and safety.

Expanded Applications: Synergy with Other Related Equipment

In addition to the three types of equipment introduced in this article, the chocolate production line also requires other equipment such as chocolate panners, sjokolade omhul masjiene, and packaging machines to improve production efficiency. Chocolate wrapping machines can add outer layers such as nuts or candies to the finished product to enrich the taste. Chocolate packaging machines are responsible for packaging on demand to ensure a beautiful appearance, easy transportation, and sales.

Market Demand Drives Equipment Innovation

With the advancement of chocolate equipment technology, the chocolate mould machine, digital chocolate tempering machine, and chocolate ball machine have greatly improved production efficiency and product quality. Manufacturers need to choose suitable equipment according to market demand to stand out in the fierce competition. Welcome to contact us to learn more about the cutting-edge technology in the industry!