Full Automatic Banana Chips Production Line

The automatic banana chips production line is an efficient and intelligent modern food processing equipment, specially built for food processing enterprises. It can produce banana slices quickly and of high quality. This production line is automatically operated from raw material treatment to finished product packaging, covering many core equipment such as a cleaning machine, peeling machine, slicer, blanching machine, frying machine, deoiling machine, seasoning machine, verpakking masjien, ens., to realize comprehensive optimization of high efficiency, lae energieverbruik, en stabiliteit.

Whether you are a small and medium-sized food enterprise or a large-scale food processing factory, this production line can help you improve the efficiency of banana slice production, ensure product quality, en markmededingendheid te verbeter!

Automatic Banana Chips Line Specifications

|

Produk Naam

|

Krag |

Overall Size |

Materiaal |

Verhitting |

| Blanching and peeling machine |

36.55kw |

2500*1050*1250mm |

SUS304 |

Elektrisiteit

|

|

Picking conveyor

|

0.37kw |

3000*750*850mm |

SUS 304+PVC |

/ |

| Air bubble washing machine |

2.79kw |

3000*1050*2020mm |

SUS304 |

/ |

|

Receving platform

|

/ |

1800*950*800mm |

SUS304 |

/ |

| Snyer |

0.75kw |

680*680*1100mm |

SUS304 |

/ |

|

Elevator

|

0.37kw |

2500*750*1250mm |

SUS304 |

/ |

| Automatic frying machine |

11.12kw(gas)

99kw(electricity) |

3500*1350*1600mm |

SUS304 |

Gas / Elektrisiteit

|

|

Deoiling machine

|

0.16kw |

2000*850*950mm |

SUS304 |

/ |

| Drum seasoning machine |

1.5kw |

2800*750*1800mm |

SUS304 |

/ |

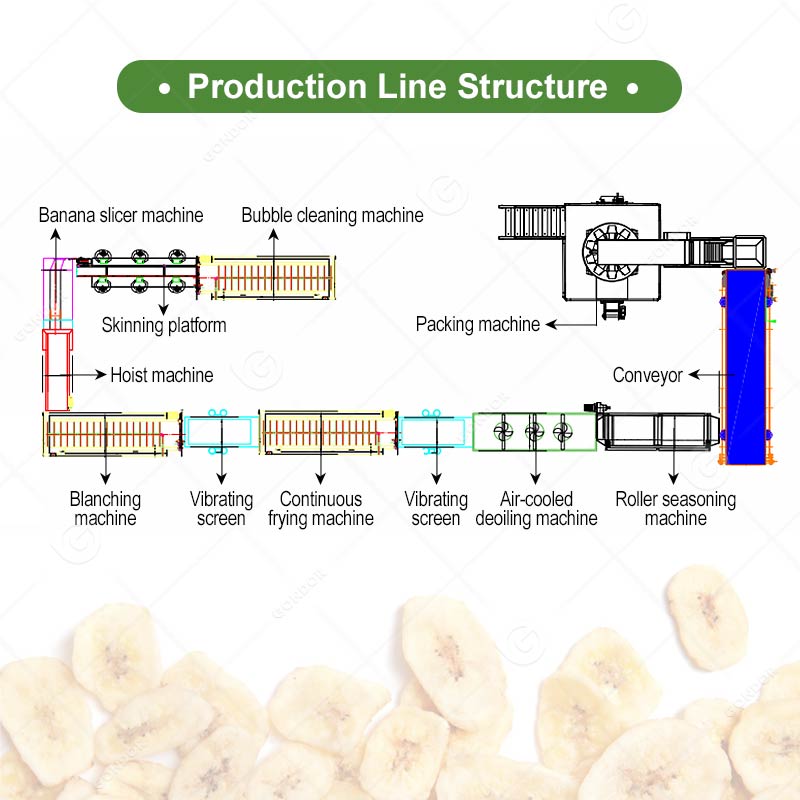

Automatic Banana Chips Line Components

From the entry of raw bananas into the workshop to the exit of finished bagged banana chips from the warehouse, the entire process is a continuous system centrally controlled by PLC, with each individual machine operating automatically in a linked manner. No manual handling is required; only 1-2 people are needed for operation. It can produce various shapes such as flat round chips, long strips, and wavy chips, and is suitable for different processes such as frying, non-frying, and low-temperature vacuum frying.

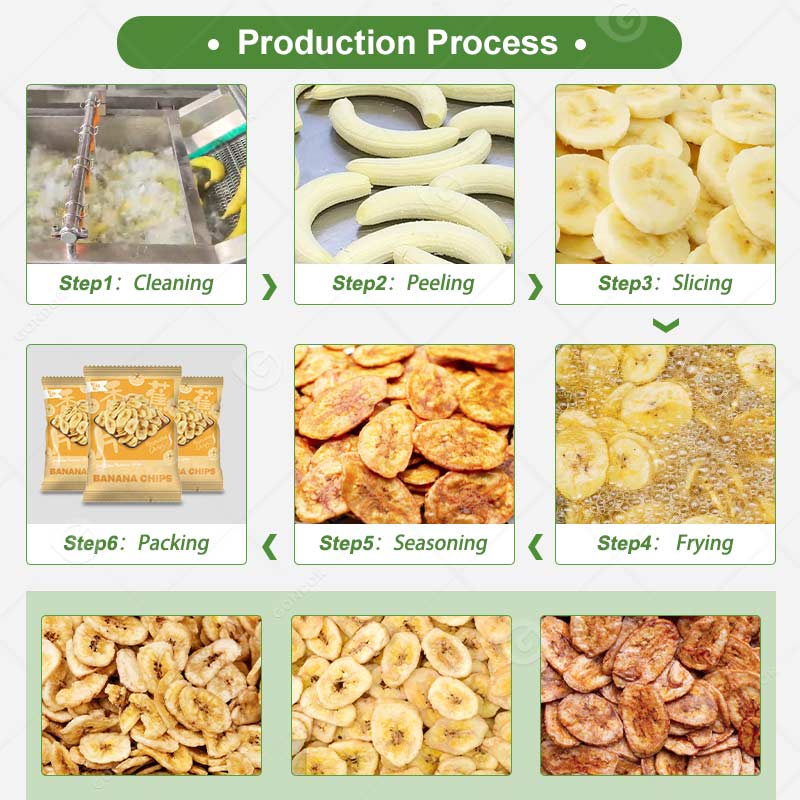

🥣 Blanching and Peeling Machine

,

softening the flesh,

removing odors,

and pre-treating the peel for subsequent peeling and slicing.

It helps improve the color and taste of the finished product,

while controlling starch release and improving frying results.

The sorting conveyor efficiently transports raw bananas and slices between processes.

It also provides a platform for manual selection and removal of substandard materials,

ensuring that products entering the next stage are neat and uniform in quantity,

improving overall production line efficiency and quality control.

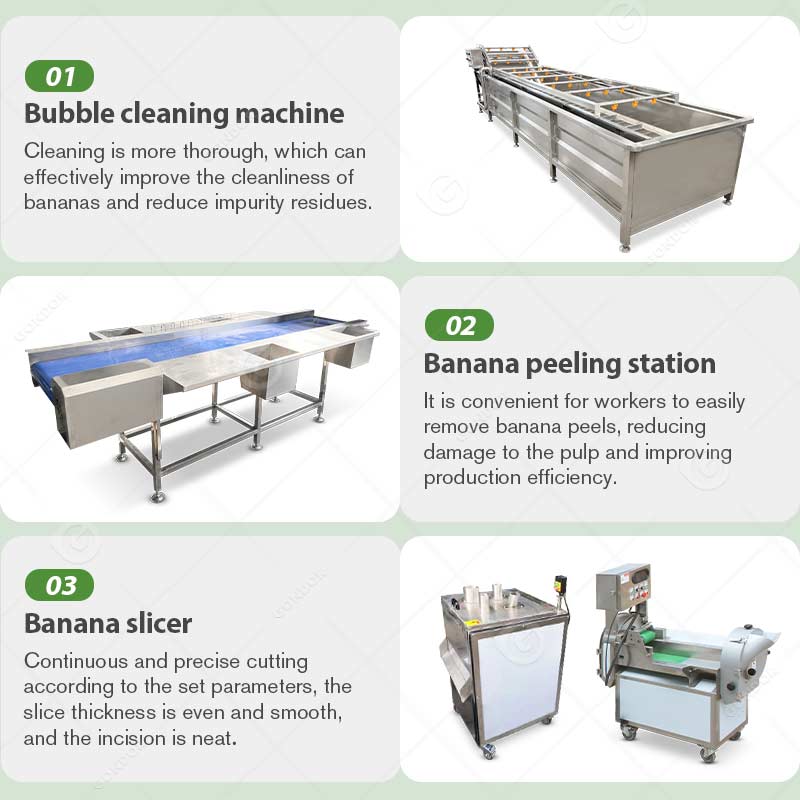

The bubble washing machine uses vibrating bubble water flow to deeply clean banana slices,

effectively removing surface dirt,

residual starch,

and fine impurities.

This provides cleaner raw materials for subsequent blanching, sny,

and frying processes,

improving the hygiene standards of the finished product.

The sorting conveyor efficiently transports raw bananas and slices between processes.

It also provides a platform for manual selection and removal of substandard materials,

ensuring that products entering the next stage are neat and uniform in quantity,

improving overall production line efficiency and quality control.

The slicing machine evenly slices peeled bananas into pieces of a set thickness.

The thickness is adjustable to meet different flavor and crispness requirements.

Precise slicing helps improve the consistency of subsequent frying and the product’s appearance quality.

The elevator (

lifting machine)

is mainly used to raise slices or intermediate materials to higher processing levels or conveying positions,

enabling vertical connection of the production line,

saving workshop space,

and maintaining continuous material transport.

The automatic fryer is the core equipment of the banana chip production line.

By controlling oil temperature and conveying speed,

it continuously frys the slices until crispy and golden brown.

Precise temperature and time adjustment ensures consistent texture and is suitable for high-volume, hoë-doeltreffendheid produksie.

The degreasing machine removes excess oil from the surface of the banana chips after frying,

reducing oil content for a healthier product,

reducing greasiness,

and creating a better surface for subsequent seasoning steps.

The drum seasoning machine is responsible for evenly adhering various dry powder and liquid seasonings to the surface of banana chips.

Rolling and vibration ensure even and stable seasoning,

and can produce finished products with different flavors according to the recipe.

Applicable Market of Plantain Chips Making Machine

VoedselverwerkingsaanlegteSnack Food ManufacturersSupermarkets and RetailersExport TradersFood OEM

Food enterprises that need continuous production can realize large-scale and efficient production.

Suitable for producing crispy banana slices, sweet banana slices and other flavors.

Packaged foods in great demand, providing standardized and stable quality banana slices.

Automated production conforms to international food hygiene standards, is suitable for export markets, and meets the needs of global consumers.

It is suitable for OEM, ondersteun pasgemaakte produksie, and meets different market demands.

Excellent Performance Advantages of Banana Chips Machine

Efficient Continuous Production

- Adopt a fully automatic design, realize continuous operation, greatly improve production efficiency, and meet mass demand.

- The equipment is equipped with automatic feeding, high-speed slicing, and precise frying control to ensure the smooth operation of each link.

Precise Process Control

- The slicer can accurately control the slice thickness to ensure that each banana slice has uniform thickness and consistent taste.

- The frying machine can adjust the temperature, which is suitable for banana slices of different varieties and thicknesses to ensure a crisp taste.

- The blanching machine can soften the pulp, optimize the frying effect, make the surface of banana slices smoother, and improve the taste.

Low Energy Consumption Design

- Using gas heating or electric heating, the temperature control is accurate and the energy consumption is optimized.

- The oil remover reduces the oil content of banana slices, improves the product quality and effectively reduces the production cost.

- The equipment structure is stable and supports all-weather operation, which greatly reduces the maintenance cost.

Flexible Seasoning Systeme

- The drum seasoning machine can evenly spread powder and spray liquid seasoning, which is suitable for different tastes such as sweet, salty, and spicy.

- Support customized formulas to adapt to different markets and consumer groups.

Smart Packaging

- The packaging machine has the functions of automatic metering, sealed packaging, ens., to ensure the accurate weight of each package of banana slices.

- Suitable for plastic bags, aluminum foil bags, vacuum packaging, and other packaging forms to improve the shelf life of products.

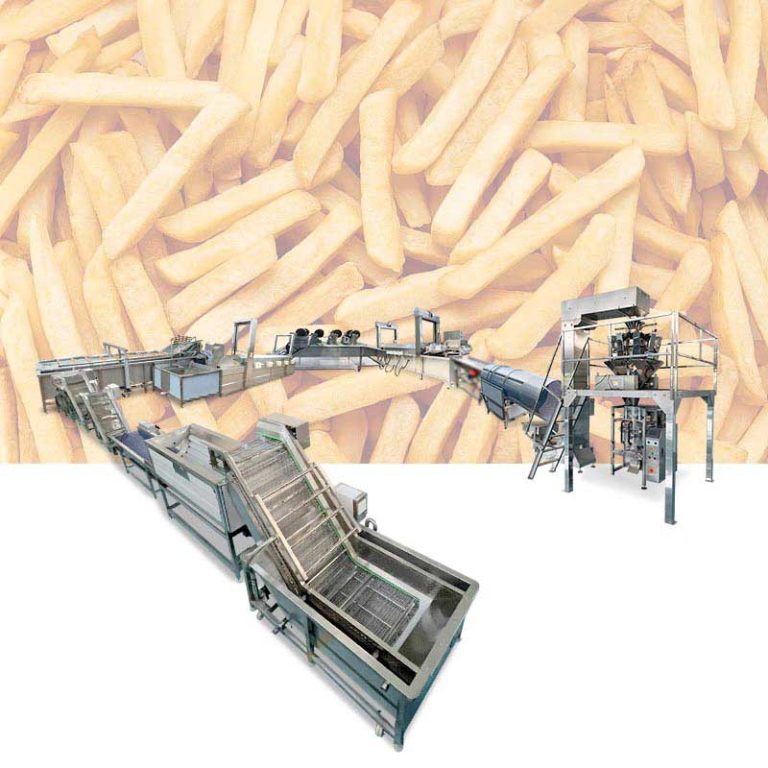

Explore More Food Processing Equipment

In addition to the banana chip production line, we also provide a series of efficient food processing equipment such as a potato chips production line, en a continuous belt dryer to meet different food production needs. If you are interested in a banana slice production line, please contact us for more technical parameters, equipment quotation, and customized scheme! We are committed to providing the best quality food processing equipment to help your business grow!