Gondor Batch Roller Candy Machine

Die batch roller candy machine is specifically designed for candy strip production. Made of thickened stainless steel, it is both safe and durable, offering low noise and high efficiency, which significantly reduces labor intensity. To operate, simply place the sugar mass at the appropriate temperature into the heat-insulated roller bed. The equipment then adjusts the spacing and speed of the strip rollers, allowing the sugar mass to be smoothly pulled into a conical sugar column and subsequently stretched into thin strips for molding. Verder, it is compatible with various molding machines. With easy operation, veelsydige funksies, and support for continuous work, this machine greatly enhances production efficiency. Algehele, this equipment is an efficient assistant in candy strip production, helping enterprises optimize their processes.

|

Naam

|

Krag(kw)

|

Gewig(kg)

|

External Dimensions(mm)

|

Kapasiteit

|

|

The batch roller

|

4.75

|

450

|

2100*600*1150

|

150-300 pieces/min

|

|

The rope sizer

|

3.3

|

430

|

1400*800*1300

|

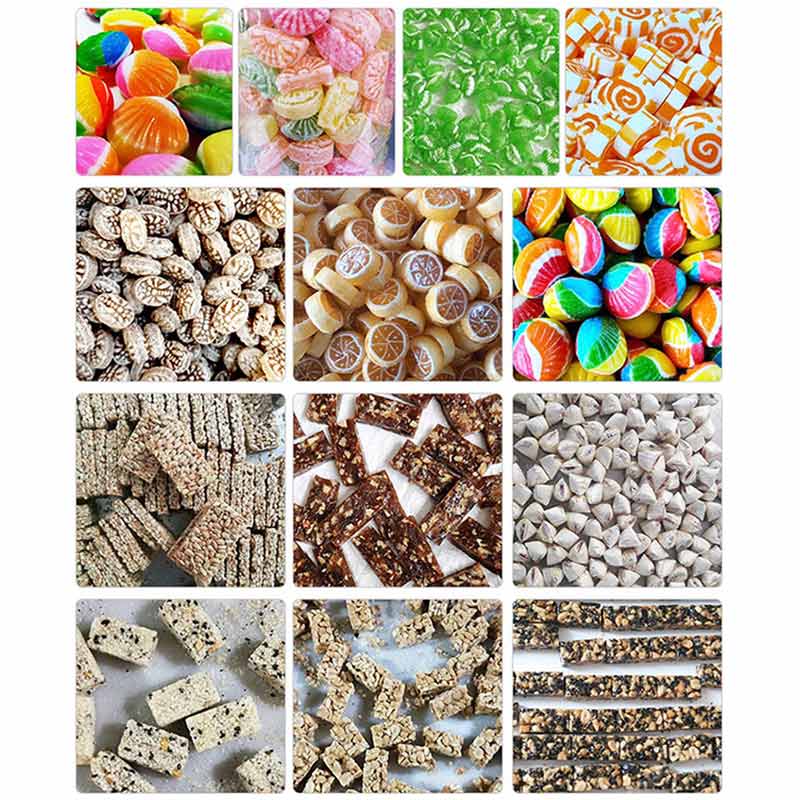

Demand Areas for the Gondor Batch Roller Candy

This efficient batch roller is widely used in multiple fields to meet different production needs due to its easy operation, strong applicability and adaptability to a variety of molding machines. Die volgende is die hoofaanvraagareas vir hierdie toerusting:

Excellent Performance Advantages of Gondor Batch Roller Machine

Gondor batch roller is widely used in the field of candy production with its advantages of high efficiency, duursaamheid, easy operation and multi-function, helping enterprises to significantly improve production efficiency and consistency of product quality. It is suitable for a variety of molding equipment and supports continuous operation, making it an ideal choice for candy production enterprises to optimize process flow, reduce costs and enhance market competitiveness.

Gondor Batch Roller Candy Machine – The Best Choice for Efficient Production

If you are looking for professional equipment to improve the production efficiency of candy, Gondor batch roller candy machine is your ideal production partner. The equipment is made of food-grade thickened stainless steel, and the operation is simple and intuitive. The extension and shaping of candy bars can be easily completed by accurately adjusting the distance and speed of rollers, and it can be smoothly docked with various molding machines, flexibly adapting to the production requirements of different scales and processes.

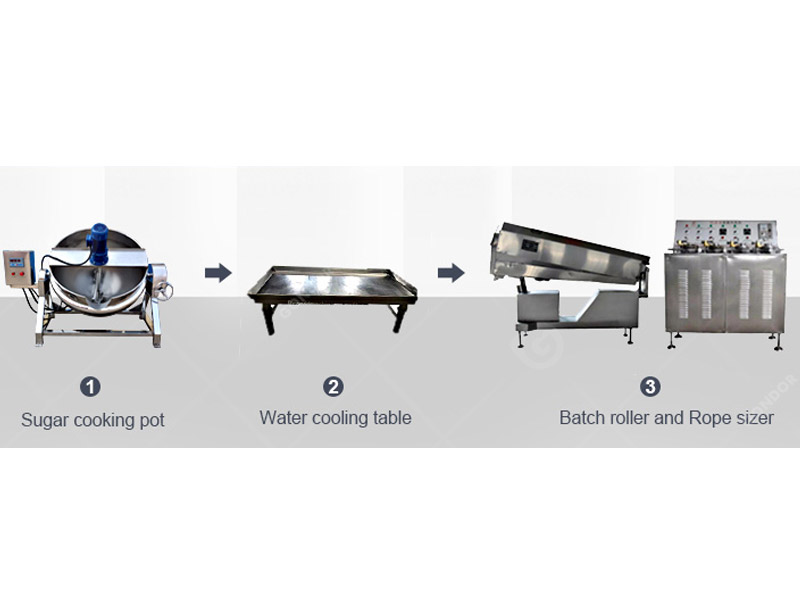

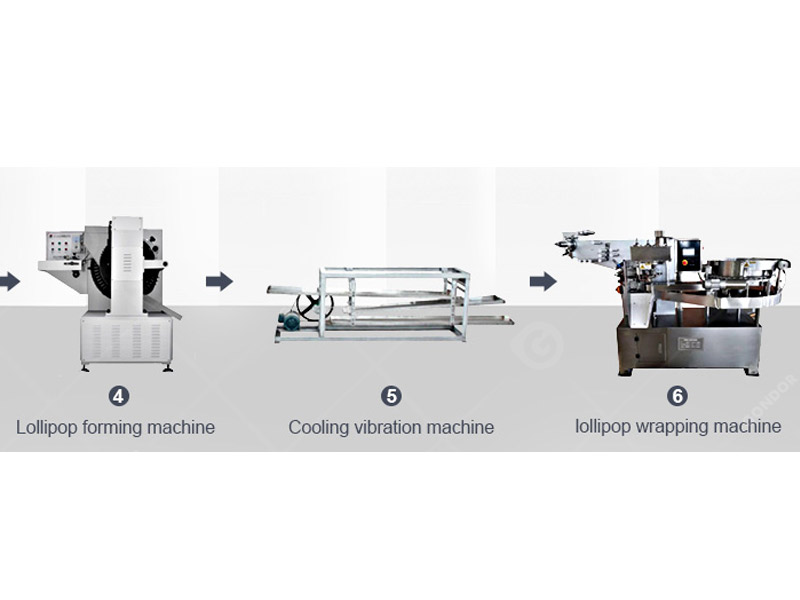

If you want to build a complete candy production line, you can use this equipment with the steam jacket kettle to realize the seamless connection from syrup boiling to candy bar forming. It can also be connected with a suigstokkie vorm masjien to efficiently produce lollipop products with the same shape. Choosing the Gondor rolling and drawing machine is not only to introduce a device, but also to create a stable, flexible and efficient candy production process. Contact us now to get customized solutions and exclusive quotations!