Gondor Commercial Ice Machine

In the modern catering and food processing industries, the quality and production efficiency of ice cubes directly affects the taste and preservation of drinks and food. An efficient and convenient ice maker machine can not only improve work efficiency but also ensure the hygiene standards of ice cubes and meet various business needs. Whether in milk tea shops, tralies, nagereg winkels, or laboratories and medical institutions, ice makers are indispensable equipment.

Commercial Ice Machines Specification

| Model |

Kapasiteit |

Grootte (mm) |

Gewig |

Krag |

| GD-CIMM300(Single head) |

300kg |

565*840*1650 |

74KG |

220V/50HZ |

| GD-CIMM350(Single head) |

350kg |

565*840*1650 |

75KG |

| GD-CIMM400(Single head) |

400kg |

565*840*1750 |

82KG |

| GD-CIMM450(Single head) |

450kg |

565*840*1750 |

82KG |

| GD-CIMM500(Single head) |

500kg |

760*840*1770 |

102KG |

| GD-CIMM600(Single head) |

600kg |

760*830*1860 |

122KG |

| GD-CIMM650(Single head) |

650kg |

760*830*1860 |

142KG |

| GD-CIMM700(Single head) |

700kg |

760*840*1900 |

121KG |

| GD-CIMM900(Two Heads) |

900kg |

1250*930*2050 |

256KG |

| GD-CIMM1000(Two Heads) |

1000kg |

1250*930*2050 |

278KG |

| GD-CIMM1300(Two Heads) |

1300kg |

1250*930*2050 |

288KG |

Gondor Ice Maker Machine – Meet the Needs of Multiple Scenarios

With the booming beverage market, consumers have higher and higher requirements for cold drinks. Die vorm, grootte, and purity of ice cubes have become important factors affecting the taste. Ice maker machine is widely used in the following industries due to their fast ice-making and customizable ice cube size.

Beverage Industry Food ServiceVoedselverwerking Medical & Laboratory

Milk tea, cocktails, soda, ens. cannot be done without high-quality ice cubes.

Coffee shops, KTVs, tralies, and other places use a lot of ice cubes, requiring fast ice-making speed and standard shape.

The purity of ice cubes is particularly important for refrigerating seafood, preserving fruits, and making ice cream.

Laboratory sample preservation and medical cooling treatment require clean and sterile ice cubes.

Our ice maker can not only meet the needs of these industries, but also ensure the purity of water through water circulation technology, avoid external pollution, and provide users with safe and hygienic ice cubes.

Gondor Commercial Ice Maker Excellent Performance

Compared with traditional ice freezing methods, commercial ice makers have excellent performance in ice-making speed, ice shape, and ease of operation with advanced technology.

Quick Ice Making

Our ice maker adopts a high-efficiency cooling system, which can produce a large amount of ice in a short time. Whether it is a milk tea shop during peak hours or a bar that needs an instant supply of ice, it can meet the needs and ensure smooth business operation.

Adjustable Ice Thickness

Through the Smart Control Panel,

users can freely adjust the ice thickness to meet the needs of different scenarios. Byvoorbeeld:

- Thick Ice: Slow melting speed, suitable for long-term refrigeration of drinks or food.

- Thin Ice: Fast cooling effect, suitable for cocktails, cold drinks, and other rapid cooling needs.

Multiple Cooling Methods Available

- Air Cooling System: Suitable for well-ventilated places, saving water resources and lowering energy consumption.

- Water Cooling System: Suitable for high-temperature environments, not affected by external temperature, and more stable ice making.

Edible Ice Cubes

Using an advanced water filter, impurities can be effectively filtered to produce pollution-free, directly edible ice cubes. Whether it is used for cold drinks, preservation, or experimental purposes, it can ensure hygiene and safety.

Stewig en duursaam, Maklik om te bedryf

- Stainless Steel Casing: Korrosiebestand, maklik om skoon te maak, ensuring that the equipment will not rust after long-term use.

- Intelligente beheer: Users can start ice making with one button, eenvoudige operasie, and convenient maintenance.

- Uniform Ice Cubes: Each batch of ice cubes has the same shape and size to ensure the uniformity of the appearance and taste of the drink.

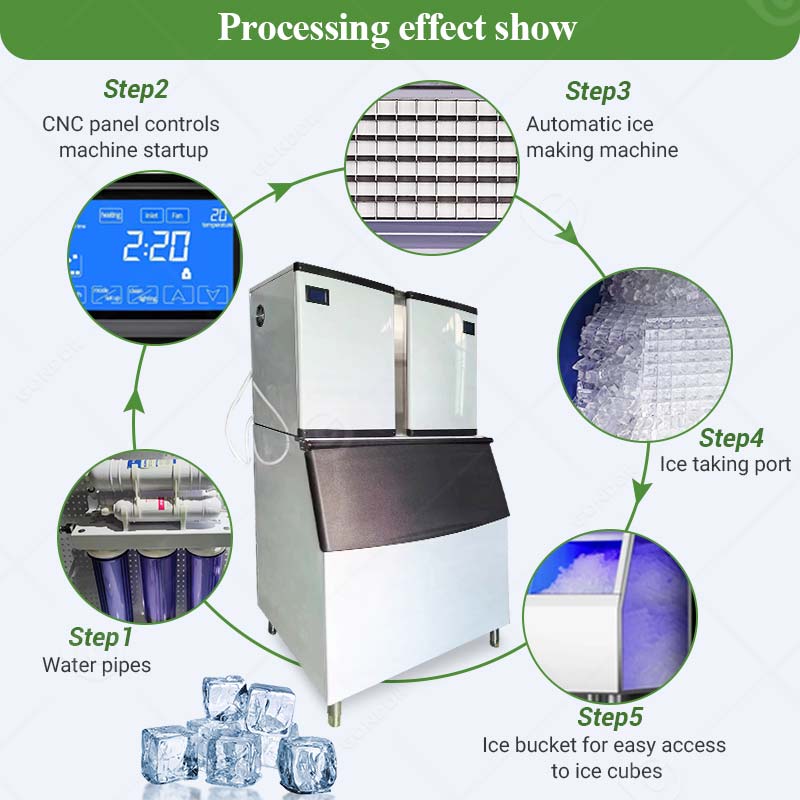

Operating Principle of a Commercial Ice Maker Machine

A water pump delivers filtered water to the evaporator surface or mold cavity.

Refrigerant evaporates and absorbs heat in the evaporator at -10

to -18°C,

causing water to freeze layer by layer.

Temperature or time sensors determine the ice thickness.

The compressor performs high-temperature defrosting in reverse or the heating wire slightly melts the ice,

causing it to fall off due to its own weight.

Na ontdooiing,

the system automatically resets and begins the next ice-making cycle.

More Refrigeration Equipment to Meet All Needs

In addition to the ice maker machine, we also provide a variety of efficient refrigeration equipment to meet the needs of different scenarios:

- Tube Ice Maker Machine – Produces hollow cylindrical ice cubes with slow melting speed, suitable for bars, beverage shops, and food processing industries.

- Industriële Flake Ice Machine – Produces large-area thin flake ice cubes, widely used in seafood preservation, meat processing, koue ketting vervoer, en ander nywerhede.

If you are looking for efficient and reliable ice-making and refrigeration solutions, please contact us for more product details and let our smart refrigeration equipment help your business take off!

Gondor Ice Machine Commercial FAQ

-

1: How fast does this machine make ice? Can it handle peak business hours?

A: Ja.

This series of ice machines uses a high-efficiency refrigeration system,

with an initial ice-making time of only 10-20 minute.

It can quickly and in large quantities produce ice,

specifically designed to meet the peak business demands of milk tea shops, tralies,

and other similar establishments, gladde werking te verseker.

-

2: Are the produced ice cubes hygienic? Can they be directly added to drinks?

A: Absoluut.

The machine has a built-in advanced water filtration system that effectively removes impurities from the water,

ensuring that the produced ice cubes are clean, veilig,

and meet edible standards.

Whether used for chilled drinks,

preservation,

or experiments,

it meets strict hygiene requirements.

-

3: Can the size and thickness of the ice cubes be adjusted?

A:

Through the machine’s intelligent control panel,

users can freely adjust the thickness of the ice cubes to suit different uses. Byvoorbeeld,

thick ice melts slowly,

suitable for long-term food refrigeration;

thin ice cools quickly,

suitable for rapidly chilling drinks.

-

4: Is the machine certified? Is its quality and safety guaranteed?

A: Ja,

it’s guaranteed.

Gondor ice makers have passed numerous international authoritative certifications,

including ISO 9001

quality management system certification,

CE safety certification,

and ETL certification.

Their stainless steel casing is also robust and corrosion-resistant.

From production standards to materials,

they demonstrate a commitment to quality and safety.

-

5: Should I choose an air-cooled or water-cooled model?

A:

This depends on your installation environment.

Air-cooled models rely on air for heat dissipation,

saving more water and suitable for well-ventilated locations.

Water-cooled models use water flow for cooling,

operating more stably without being affected by high ambient temperatures,

and are suitable for scenarios with higher ambient temperatures or abundant water supply.

-

6: Besides cube ice, can it produce other shapes of ice?

A:

According to the official website,

the models introduced on this page mainly produce cube ice,

but ice cube sizes can be customized according to requirements.

Gondor also offers other types of ice-making equipment,

such as tube ice machines for producing hollow cylindrical ice and flake ice machines for the food industry.