Gondor Industrial Flaked Ice Machine

Op die gebied van moderne industriële en kommersiële verkoeling, die flake ys masjien het 'n ideale keuse vir voedselverwerking geword, koue ketting vervoer, chemiese industrie, beton verkoeling, en ander nywerhede as gevolg van sy hoë doeltreffendheid, energiebesparing, en gerief. Dit kan nie net vinnig hoë kwaliteit vlokkys produseer nie, maar verseker ook die varsheid van kos, produksiedoeltreffendheid te verbeter, energieverbruik te verminder, en bring groter ekonomiese voordele vir ondernemings.

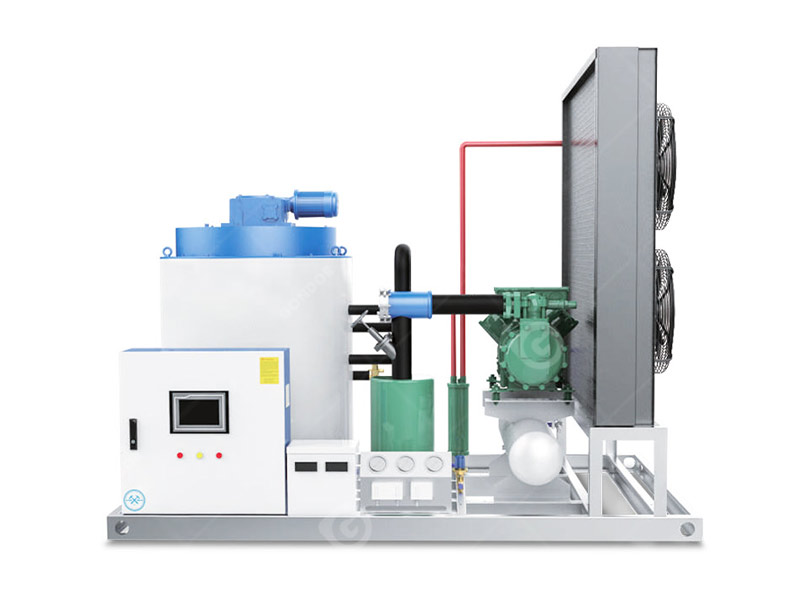

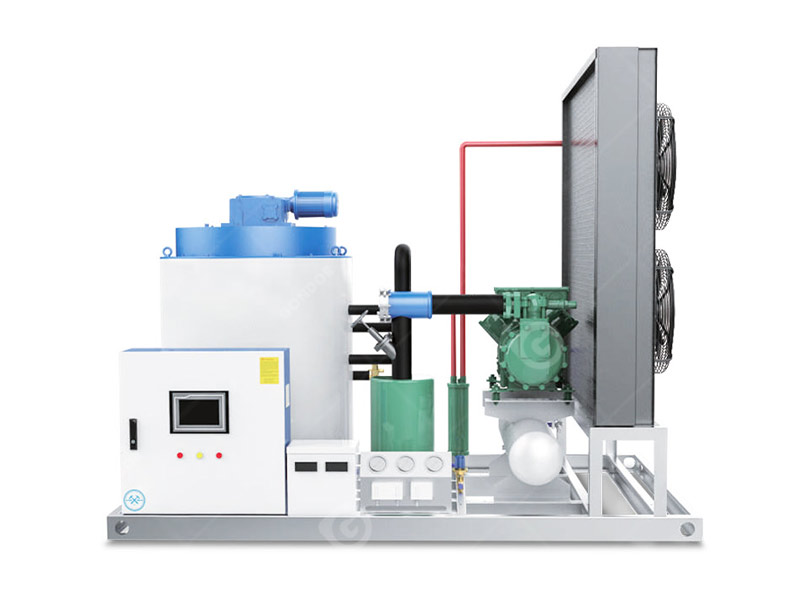

Gondor Air Cooled Flake Ice Machine

Gondor Water Verkoelde Flake Ice Machine

Kommersiële Industriële Flake Ice Machine Spesifikasie

|

Model

|

Kapasiteit |

Grootte |

Gewig |

Verpakkingsgrootte |

Verpakking gewig

|

|

GD-1

|

500KG/dag |

1100*800*710mm |

220kg |

1200*900*810mm |

250kg |

| GD-2 |

1000KG/dag |

1100*800*810mm |

245kg |

1200*900*910mm |

275kg

|

|

GD-3

|

2000KG/dag |

1310*970*1200mm |

450kg |

1410*1070*1300mm |

480kg |

| GD-4 |

3000KG/dag |

1650*1210*1420mm |

650kg |

1750*1310*1520mm |

680kg

|

Die eerste keuse vir die verkoelingsbedryf – Gondor Industrial Flake Ice Machine

VoedselverwerkingAkwakultuurBetonverkoelingChemiese industrieKouekettinglogistiek

Verkoel vleis, seekos, en groente om die produkte vars te hou en lekker te smaak.

Word gebruik vir seekos vervoer en berging om te voorkom dat waterprodukte bederf.

Word in die konstruksiebedryf gebruik om kwaliteitsprobleme wat deur hoë-temperatuur konstruksie veroorsaak word, te voorkom.

Verlaag die temperatuur van chemiese reaksies om produksieveiligheid te verseker.

Van toepassing op supermarkte en verspreidingsentrums om die temperatuurbeheer-effek tydens vervoer te verbeter.

Prestasievoordele van Flake Ice Machine

Vlokkysmasjiene word wyd gebruik in voedselverwerking, koue ketting logistiek, die chemiese industrie, konstruksie ingenieurswese, en ander velde as gevolg van hul intelligente werking, vinnige ys maak, energiebesparing, en omgewingsbeskerming. Hul uitstekende werkverrigting maak hulle 'n ideale keuse vir industriële en kommersiële verkoeling. Die volgende is die belangrikste prestasievoordele van vlokysmasjiene:

Doeltreffende ys maak

Die kommersiële vlokkiesmasjien kan vinnig 'n groot aantal ysvlokkies produseer om aan die behoeftes van grootskaalse kommersiële en industriële ysmaak te voldoen.

Intelligente Operasie

Toegerus met 'n PLC intelligente beheerstelsel, ondersteun een-knoppie begin, en gebruikers kan die dikte van ysvlokkies aanpas (1-2.5mm) deur die raakskerm.

Hoë kwaliteit ysvlokkies

Vlokkys is wit en deursigtig, droog, en nie maklik om te agglomereer nie, sonder skerp kante en hoeke, en beskadig nie verkoelde items nie.

Lae verlies en hoë uitset

Neem SUS304 vlekvrye staal spiraal-yslem aan om verlies te verminder, verbeter ysmaakdoeltreffendheid en verminder bedryfskoste.

Energiebesparing en Omgewingsbeskerming

Ingevoerde kompressor + gevorderde verkoelingstegnologie, lae energieverbruik, klein verkoelingsverlies, in ooreenstemming met omgewingsbeskermingstandaarde.

Duursame struktuur

Neem materiaal van hoë gehalte vlekvrye staal aan, korrosiebestand en slytasiebestand, geskik vir langtermyn deurlopende werking.

Stabiel en betroubaar

Vertikale verdamperontwerp vermy seëlslytasie wat veroorsaak word deur die rolbewerking, verminder koelmiddellekkasie, en verleng toerusting se lewe.

Veeldoelige toepassing

Word wyd gebruik in voedselverwerking, beton verkoeling, akwakultuur, chemiese verkoeling, koue ketting vervoer, en ander nywerhede om aan verskillende behoeftes te voldoen.

Gondor Flake Ice Machine help wêreldwye verkoelingsvraag

As jou besigheid 'n meer doeltreffende oplossing vir ysmaak benodig, ons verskaf ook 'n verskeidenheid ysmaaktoerusting, soos die ysbuismasjien en ysblokmasjien, om aan die behoeftes van verskillende industrieë te voldoen. Jy is welkom om ons te kontak vir pasgemaakte oplossings vir ysmaak! Vir meer inligting, los asseblief 'n boodskap of besoek ons webwerf om jou besigheid koeler en doeltreffender te maak!

Gereelde Vrae oor Flake Ice Machine

V: Wat is die voordele van vlokkys in vergelyking met buisys en blokys?

A: Vlokkys het 'n groter oppervlak en koel vinniger af; dit is droog, los, en maklik om te vervoer; dit het geen skerp hoeke nie en beskadig nie die produk nie; dit produseer voortdurend ys sonder dat dit nodig is om te vergruis.

V: Wat is die daaglikse krag- en waterverbruik van 'n industriële vlok-ysmasjien?

A: Kragverbruik per ton ys ≈ 45 kWh, waterverbruik van die sirkulerende waterstelsel < 0.1 m³/t; dit bespaar 15–25% meer energie as tradisionele pekeltenk-ys maak.

V: Wat is die waterkwaliteitvereistes vir die toerusting?

A: Kraanwater met TDS < 200 ppm is voldoende; seewater tipe kan seewater direk gebruik, maar die verdamper benodig 'n korrosiebedekking; dit word aanbeveel om die watertenk skoon te maak en elke keer te filter 2 maande.

V: Wat is die ysbergingstyd?

A: Geïsoleerde berging (100 mm poliuretaan) by -5 ℃, vlokkies kan vir 24–36 uur gestoor word; die stoor is toegerus met 'n roterende hark om die ys los te hou en klonter te voorkom.

V: Wat is die slytasie dele en hul lewensduur?

A: Ysskaatse hou 8–12 maande (kan twee keer herskerp word); laer ghries elke aangevul 2000 ure; sirkulasiepomp seëls vir 1 jaar; jaarlikse onderhoudskoste ongeveer 2–3% van die aankoopprys van toerusting.