Gondor Industrial Ice Crusher Machines

A commercial ice crusher machine is a multifunctional equipment designed to efficiently crush large blocks of ice bricks into ice particles of different sizes. The machine drives the internal adjustable cutter set through the high-performance copper core motor, which can easily and quickly crush 1 ton of ice into the required size within 1 hour, arbeid en tyd bespaar. Kompakte struktuur, equipped with a stable frame and universal wheel, easy to move and operate, it is an ideal choice for various commercial and industrial purposes.

Commercial Ice Crusher Machine Specification

|

Model

|

JH-300 |

JH-450 |

JH-500 |

JH-600

|

|

Kapasiteit

|

1-2t/h |

3-5t/h |

5-7t/h |

10t/h |

| Grootte |

700*500*920 |

800*600*1040 |

800*700*1040 |

900*800*1040

|

|

Gewig

|

60kg |

85kg |

115kg |

165kg

|

Application Field of Industrial Ice Crusher Machine

Industrial ice crusher machine is widely used in many industries, insluitend maar nie beperk nie tot:

Spyseniering industrieSeekos Bewaring & TransportationSki resorts & Recreational FacilitiesMedical & Laboratory UseChemiese industrie

Making iced drinks and refrigerating ingredients.

Ensure the freshness of seafood during transportation.

Large-scale ice making and snow laying.

Cool and preserve medicines and samples.

Used for cold storage of temperature-sensitive materials.

Outstanding Use Advantages of Industrial Ice Crusher

Fast Ice Breaking

Using a high-efficiency electric system, 1 ton of ice can be broken in one hour, which is especially suitable for a commercial environment with high-efficiency requirements.

Customizable Ice Size

Through the configuration of knife sets with different shapes, coarse-grained ice can be broken and fine smoothies can be made.

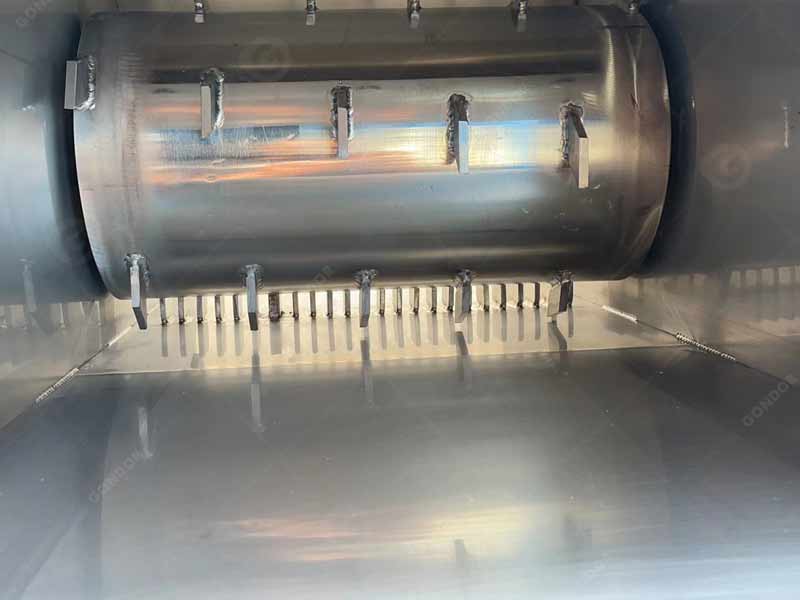

Cutter Adjustable and Customizable Blades

Customize cutter teeth with different shapes and hardness according to customer requirements, easily adapt to different specifications of ice bricks, and be flexible and practical.

Stable Construction

The design of the bottom bracket+anti-skid foot pad ensures smooth operation and no shaking, which improves service life and ensures safe operation.

Large Feed Inlet

It is suitable for putting ice bricks of various sizes, reducing the preparation for cutting and improving the overall efficiency.

High-Efficiency Motor System

Adopt an all-copper core motor, which has strong power, fast heat dissipation, and low noise, and is suitable for long-term continuous operation.

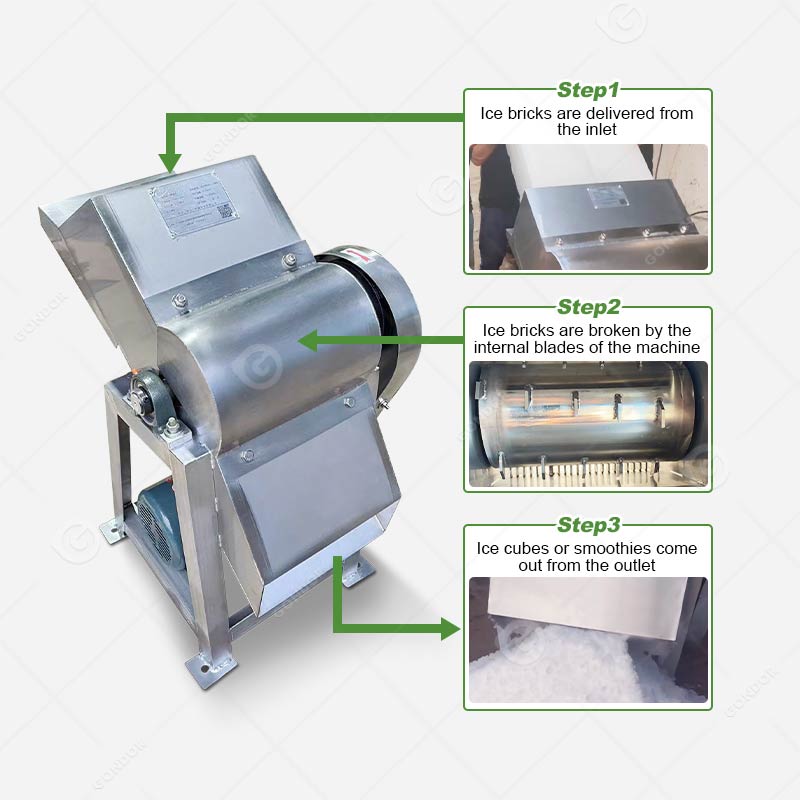

Gebruikersvriendelike werking

It only takes three steps: putting in ice bricks → starting the machine → outputting crushed ice, and novices can get started quickly without complicated training.

Portable & Maklike instandhouding

The ice crusher is small in size, with universal wheels and easy to move. But also has a simple structure, easy disassembly and washing, en lae onderhoudskoste.

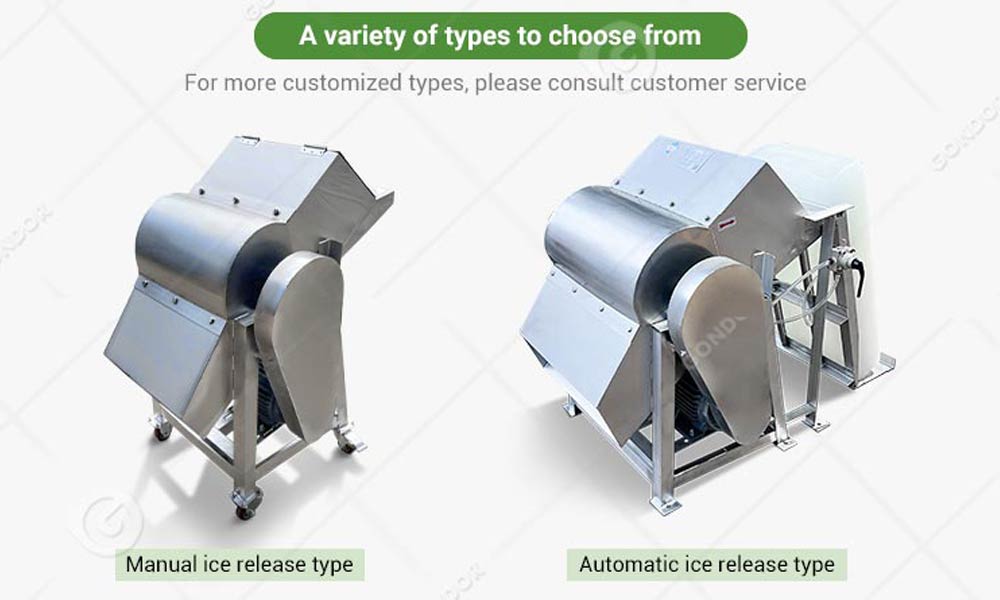

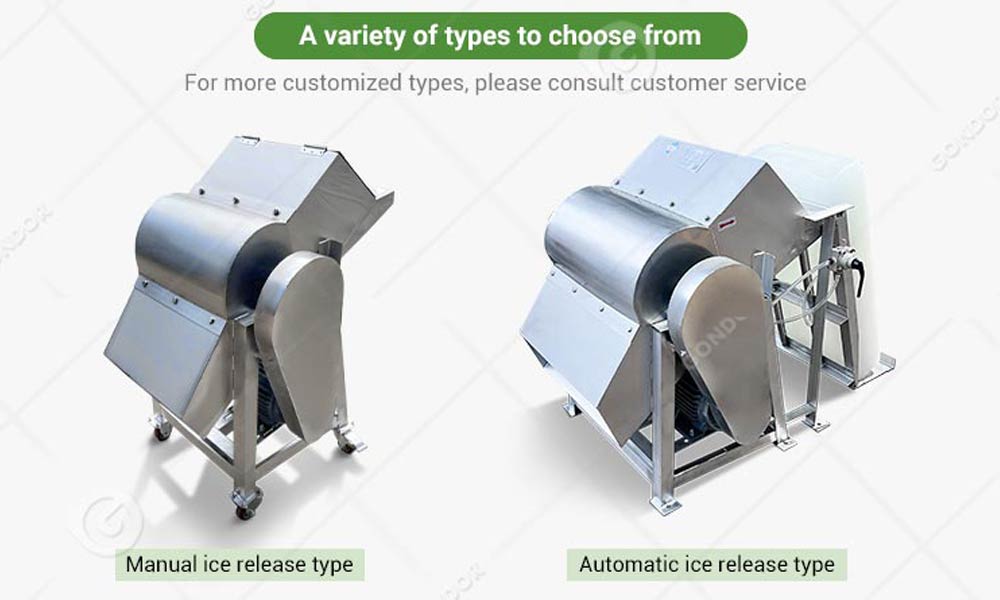

Customized Service and Supporting Recommendation

We provide personalized customization service, and configure different knife sets, ice discharging sizes, and motor power according to the actual needs of customers. Terselfdertyd, we recommend using it with the following equipment:

- Ysblokmasjien: Continuously provide high-quality ice bricks to ensure the supply of crushed ice.

- Cold Storage Room: Immediately store after breaking ice and keep the temperature low.

Efficient and Stable Ice Crushing Solution

As jy op soek is na 'n doeltreffende, duursaam, and multifunctional ice crusher, a commercial ice crusher machine will be your ideal choice. Whether it’s a daily catering application or large-scale industrial ice-making demand, we can provide you with a one-stop solution. Welcome to contact us for more customization options and supporting products to start your intelligent ice-making journey! Consult now for an exclusive quotation and technical support!

Commercial Industrial Ice Crusher Machine FAQ

- V: Can the size of the crushed ice be adjusted?

A:

This machine is designed with flexibility.

By adjusting the internal blade spacing or changing to different screen sizes,

you can achieve different results,

from granular ice (

for seafood preservation and concrete cooling)

to finer crushed ice (

for beverage processing).

It is mainly used for the rapid crushing of large industrial-grade ice blocks,

and the output is usually irregularly shaped ice granules.

- What size ice blocks can this machine process directly?

The industrial ice crusher has a wide feed inlet design.

Depending on the model,

it can directly feed in standard large ice blocks of 5-50kg.

Its high-strength crushing rotor can instantly bite and crush the ice blocks,

eliminating the need for manual pre-crushing and greatly improving the efficiency of large-scale ice use.

- 3. Are the blades prone to wear?

The core components of the ice crusher use specially treated high-hardness alloy steel or reinforced stainless steel blades.

This material boasts exceptional impact and abrasion resistance,

maintaining its sharpness even when handling high-density,

ultra-low-temperature hard ice.

Verder, the blade assembly is designed for easy replacement, facilitating future maintenance.

- 4. Besides the catering industry, what other industries is this machine suitable for?

A:

Ice crushers have a wide range of applications.

Beyond restaurant chains,

they are frequently used in:

Fisheries and Logistics: Large-scale ice packing and preservation for fishing vessels and seafood markets.

Chemical/Construction: Cooling concrete mixing (to prevent cracking).

Ice Factories: As part of automated production lines for the secondary processing of large blocks of ice into loose ice.