Doeltreffende en energiebesparende deurlopende maasvervoerbanddroër

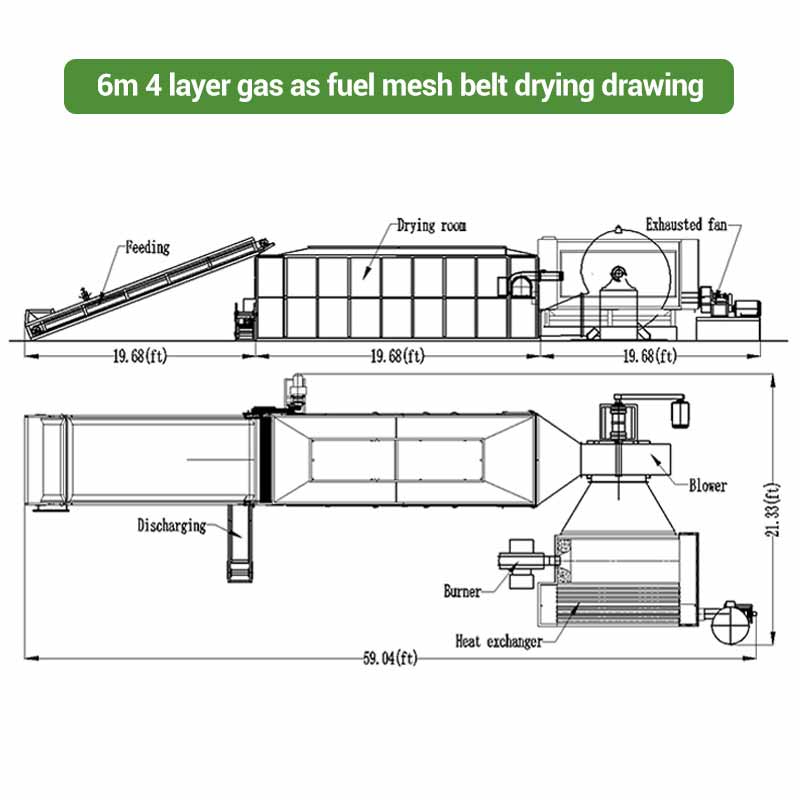

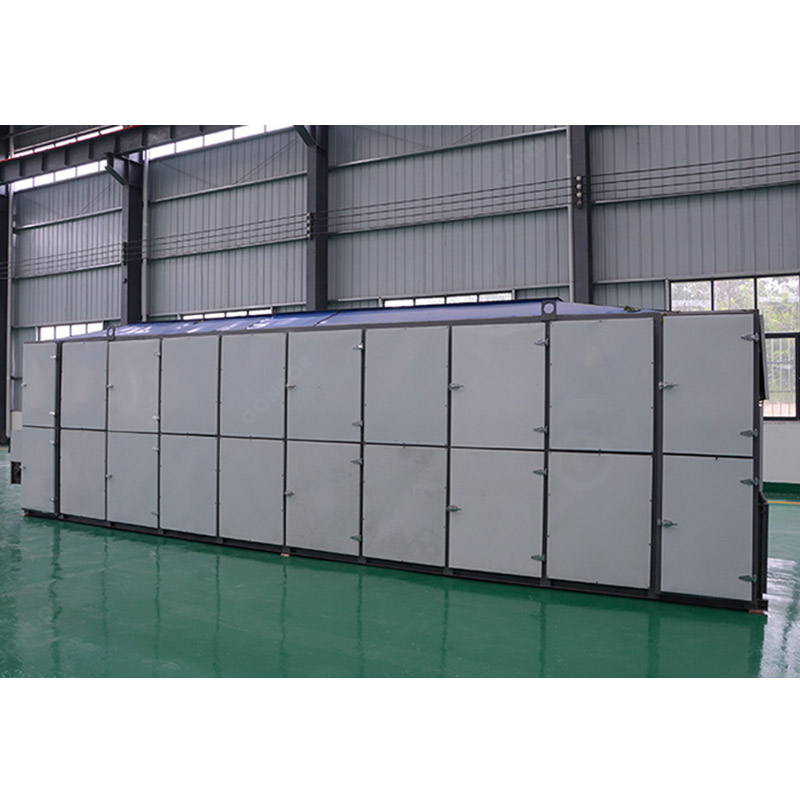

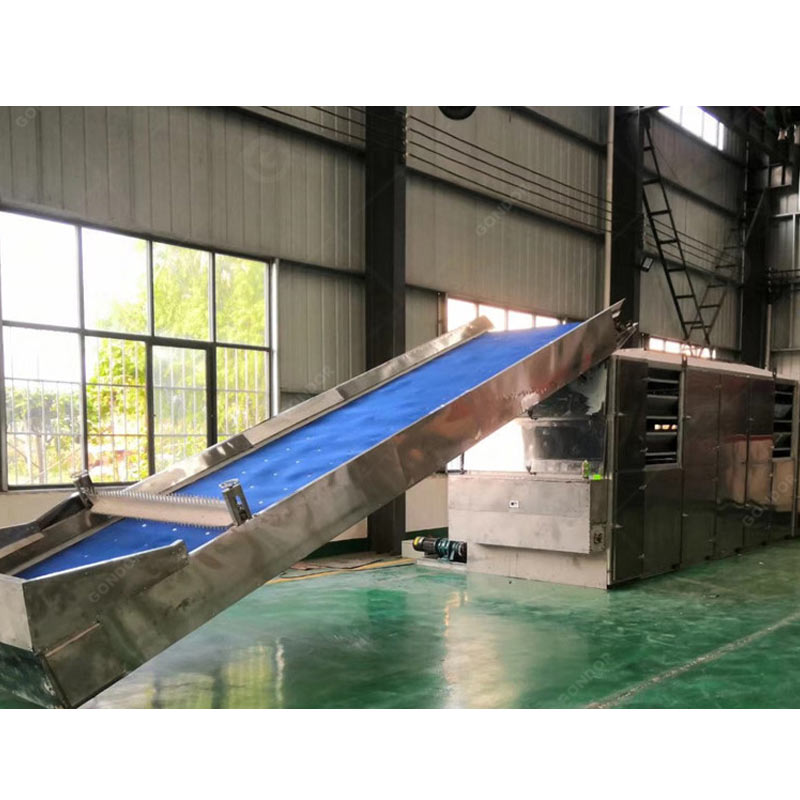

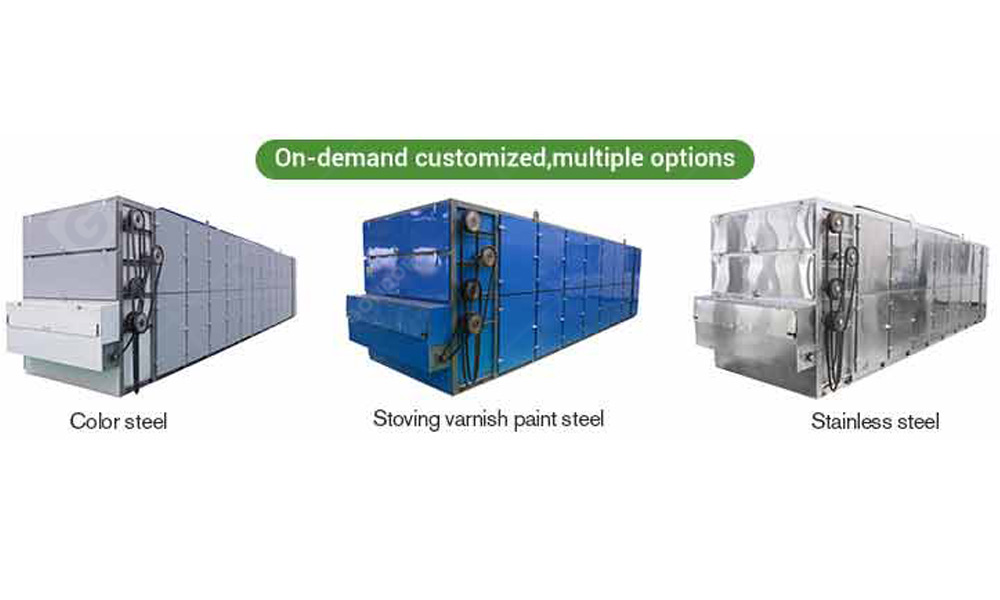

Deurlopende maas vervoerband droër is 'n doeltreffende, energiebesparende droogoplossing wat warm lug as die droogmedium gebruik. In hierdie stelsel, materiaal word eweredig versprei en voortdurend deur veelvuldige lae vlekvrye staal-gaasbande vervoer. Soos die warm lug die materiaal van die onderste na die boonste laag binnedring, vinnige en deeglike droging word behaal. Intussen, vog word van bo af afgevoer, en die gedroogde produk word via die afvoervervoerband uit vervoer. Die toerusting ondersteun verskeie hittebronne, insluitend elektrisiteit, gas, en diesel, wat gebruikers toelaat om die gerieflikste en mees ekonomiese opsie te kies. Verder, hitte word eweredig versprei om 'n besoedeling-vrye droogproses te verseker, en die temperatuur, humiditeit, en lugvolume kan almal intelligent verstel word. Daarbenewens, sy hoësterkteketting is slytvast, terwyl die voedselgraadse vlekvrye staalskerm veiligheid en duursaamheid verseker. Hierdie droër is veral geskik vir kleinskaalse verwerking van groente en vrugte, maak dit 'n ideale keuse vir klein en mediumgrootte produksie.

| Model | GD-8 | GD-9 | GD-10 | GD-12 |

| Laag | 4 lae, 5 lae, 6 lae | |||

| Materiaal dikte | 10-70mm | |||

| Droog temperatuur | 40~120°C | |||

| Humiditeit verminder | 75% aan 8% (Pasgemaak) | |||

| Droog tyd | 0.5-5 ure | |||

| Krag van hoofenjin | 1.5kw | 1.5kw | 2.2kw | 3kw |

| Warm lug trek waaier | 15kw | 15kw | 22kw | 22kw |

| Vervoerband afvoer | B500(0.12kw) | B500(0.12kw) | B500(0.12kw) | B500(0.12kw) |

| Let wel:Die bogenoemde parameters is vir verwysing, ons pas die masjien aan volgens kliënte se vereistes en bied die beste oplossings. | ||||

Hoofsaaklik toepaslike markte vir Gondor Mesh-gordeldroër

Van toepassing op die droging van landbouprodukte soos groente, vrugte, speserye en geurige tee, om die toegevoegde waarde van landbouprodukte te verhoog en die raklewe te verleng.

Word wyd gebruik om voedsel soos vleis en neute te droog om voedselhigiëne en droogdoeltreffendheid te verseker.

Geskik vir klein groepproduksie, die verskaffing van gerieflike droogoplossings vir boere en familieverwerkingsaanlegte.

Veral geskik vir ondernemings met daaglikse verwerkingskapasiteit hieronder 5 ton, voldoen aan die behoeftes van klein en mediumgrootte produksie en voldoen aan omgewingsbeskermingsvereistes.

As gevolg van sy hoë doeltreffendheid, energiebesparing en groen omgewingsbeskermingseienskappe, dit voldoen aan die vereistes van omgewingsbeskermingsbeleide, en sommige streke kan ook masjienaankoopsubsidies kry.

Ondersteun 'n verskeidenheid van hittebron opsies, soos biomassa en nuwe energie, in lyn met die ontwikkelingstendens van nuwe energie.

Beduidende mededingende voordele van Gondor Group Continuous Belt Dryer

Hoë doeltreffendheid en energiebesparing – Gondor-vervoerbanddroër

Gondor deurlopende gaas vervoerband droër bied jou doeltreffende, deurlopende en energiebesparende droogoplossings. Die toerusting gebruik multi-laag vlekvrye staal gaas gordel transmissie, en die sirkulerende warm lug dring die materiaallaag eweredig binne om die vinnige en deeglike droogeffek te verseker. Dit ondersteun baie soorte hittebronne soos elektriese energie, gas en dieselolie, en is toegerus met intelligente temperatuurbeheer en humiditeitsaanpassingstelsel om ten volle outomatiese werking te realiseer en aan die vereistes van omgewingsbeskerming en skoon produksie te voldoen. Dit is veral geskik vir grootskaalse droogverwerking van groente, vrugte, Chinese kruiemedisyne en vleisprodukte, wat produktiwiteit effektief kan verbeter en energieverbruik kan verminder.

As jy hoër vereistes het vir die behoud van aktiewe bestanddele en vorme van materiale, jy kan verder saamwerk met a vakuum vriesdroogmasjien om 'n volledige droogproduksielyn te vorm van konvensionele droging tot hoë-end vriesdroog, wat 'n wyer reeks produkbehoeftes en toepassingscenario's dek. Welkom om ons dadelik te kontak om pasgemaakte droogskema en professionele seleksie-ondersteuning te kry, en begin 'n nuwe stadium van doeltreffende en intelligente droogproduksie!