Gondor Auto Groen Piesangskilmasjien

Onder die agtergrond van die vinnige ontwikkeling van die globale piesangbedryf, die toerusting met hoë doeltreffendheid, sterk aanpasbaarheid, en hoë afskiltempo is veral krities. Die weegbree skiller masjien is spesiaal ontwerp vir gestandaardiseerde en grootskaalse verwerking, wat handvoeding en outomatiese afskiltegnologie kombineer om vinnige afskilfering te realiseer, vel en vleis skeiding, en volledige pulpuitset, en verbeter verwerkingsdoeltreffendheid en produkkwaliteit. Die hele masjien is gemaak van 304 vlekvrye staal, wat duursaam en maklik is om skoon te maak, en voldoen aan die internasionale voedselveiligheidstandaarde. Kompakte ontwerp, gerieflike werking, en eenvoudige onderhoud. Dit kan hanteer oor 150 kilogram piesangs per uur en is geskik vir spyseniering, voedselverwerking, en vrugte diep verwerking.

Groen Weegbree Piesangskilmasjien Parameters

| Model |

Spanning |

Krag |

Vermoë |

Gewig |

Grootte |

| GD-S |

220V |

0.75kw |

100kg/h |

54kg |

570*480*1010mm |

| GD-1 |

380V |

0.4KW |

150kg/h |

94kg |

950*730*930mm |

| GD-2 |

380V |

0.74KW |

300kg/h |

230kg |

2100*1060*1040mm |

Die toepaslike industriële omvang van Green Plantain Peeler

Of jy piesangprodukte uitvoer of dit aan die plaaslike mark verskaf, die groen plantain skiller kan stabiele en volhoubare verwerkingsondersteuning vir ondernemings bied. Hierdie toerusting word wyd gebruik in:

VoedselverwerkingsfabriekSentrale kombuis van restaurantKouekettingverspreidingsondernemingsPrimêre Verwerkingsbasis van Landbouprodukte

Besef die vinnige skil van piesangs en verbeter die produksievermoë, wat geskik is vir die verwerking van piesangskywe, piesangsous, en ander produkte.

Hanteer piesanggrondstowwe doeltreffend, verbeter die spoed van maaltydvoorbereiding, geskik vir grootskaalse spysenieringsvoorbehandeling.

Standaardiseer piesangverwerking, verseker die integriteit van pulp voor vervoer, en varshouverspreiding te vergemaklik.

Skil ter plaatse om die kwaliteit van grondstowwe te verbeter en om piesangpulp van hoë gehalte te verskaf vir daaropvolgende verwerking.

Uitstekende prestasievoordele van groen piesangskilmasjien

Skoon Peeling

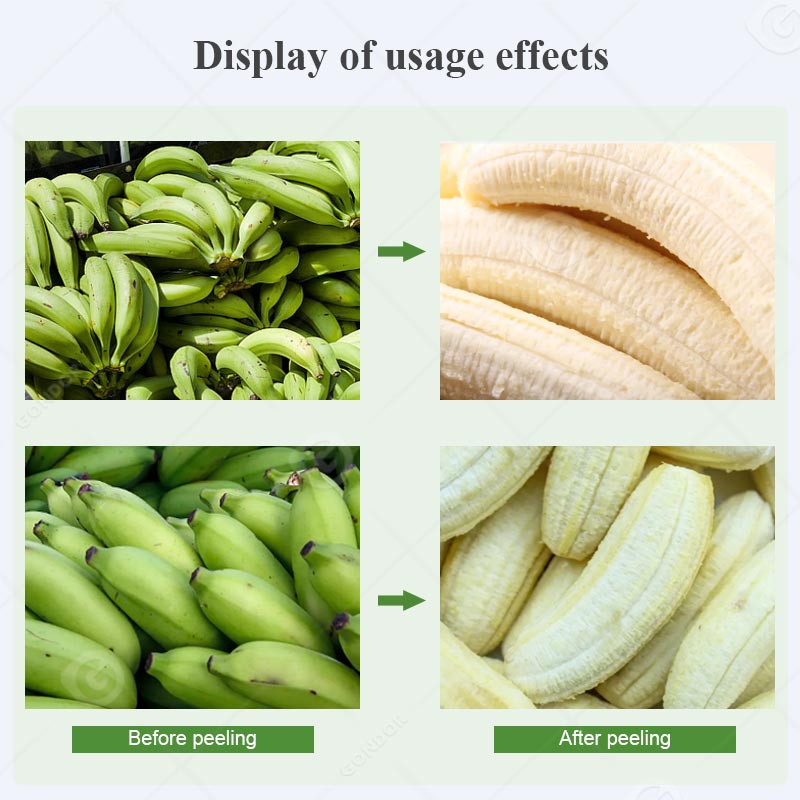

Die unieke skilstruktuur verseker dat elke piesang skoon geskil kan word, en die pulpoppervlak is glad en onbeskadig, wat perfekte grondstowwe vir latere verwerking soos vinnige vriesing verskaf, droogmaak, en sny.

Hoë integriteit van piesangvleis

Wetenskaplike afskilhoek en spoedbeheer kan die pulp byna onbeskadig maak, aansienlik verbeter die finale produk koers, en verminder die vermorsingsyfer.

Universele verenigbaarheid

Maak nie saak hoe die grootte is nie, kromming, en vorm van piesangs verander, die toerusting kan akkuraat aangepas en geskil word, en dit is 'n alomvattende toerusting om piesangspesies uit verskillende produserende gebiede te hanteer.

Maklike werking

Toegerus met 'n eenhandige voerinlaat, outomatiese piesangskil-uitlaat, volledige pulpuitlaat, en noodstopknoppie, die operasie is veiliger en doeltreffender.

Outomatiese skeiding

Die geskilde piesangskil en pulp word outomaties geskei en uitgevoer, wat handsorteertyd bespaar en die verwerkingsdoeltreffendheid van die monteerlyn aansienlik verbeter.

Snackkos produksie lyn

Dit is 'n belangrike stuk toerusting aan die voorkant van die produksielyn vir versnaperinge soos piesangskyfies en gebraaide piesangs.

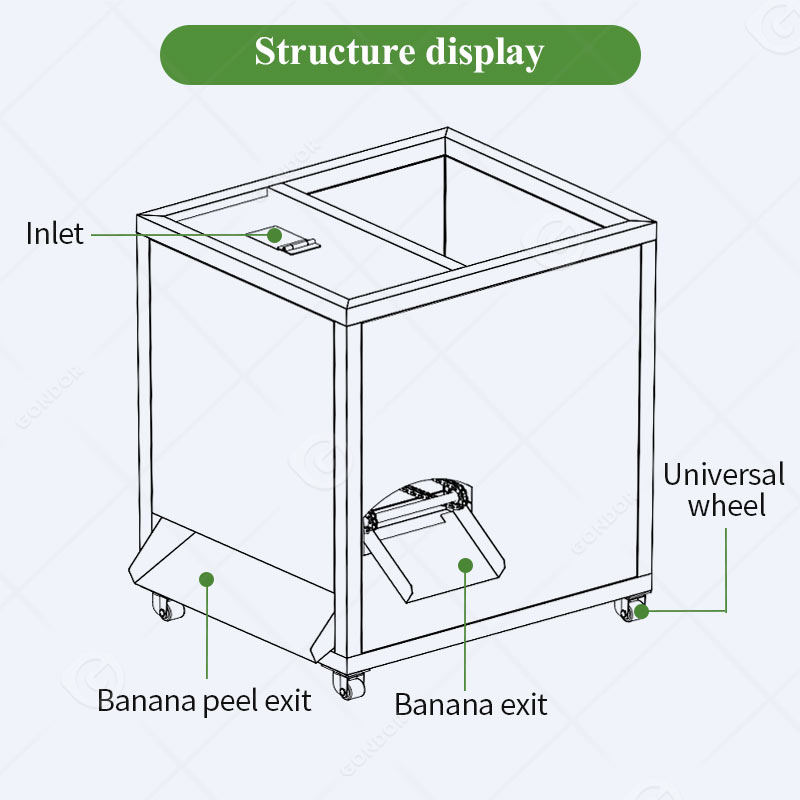

Piesangskilmasjienstruktuur: Modulêre en Voedselgraad-ontwerp

'n Tipiese industriële-graad piesangskilmasjien gebruik 'n modulêre ontwerp, met hoofkomponente gebou rondom die beginsels van doeltreffende afskilfering en higiëniese veiligheid

As die basis van die toerusting, alle komponente is van voedselgraad gemaak 304 vlekvrye staal. Hierdie materiaal beskik oor uitstekende weerstand teen korrosie en slytasie, en sy gladde oppervlak is maklik om skoon te maak, voldoen ten volle aan die higiënevereistes van voedselverwerkingstoerusting.

Tipies ontwerp as 'n tregter of skuins geut, fasilitering van gesentraliseerde en deurlopende voeding van grondstowwe deur die operateur. Sommige modelle beklemtoon a “enkelhand voeding” ontwerp om mens-masjien interaksie doeltreffendheid te verbeter.

Dit is die hart van die masjien, bestaande uit 'n pasgemaakte afskillem of wrywingrolstelsel. Die geometrie en rangskikkingshoek van die lemme, asook die materiaal en tekstuur van die rollers, is deurslaggewend in die bepaling van die afskil-effek en die integriteit van die vrugtepulp.

Krag- en transmissiestelsel

Bestaan uit 'n motor, verkleiner, dryfas, en gordel/ketting, hierdie stelsel verskaf stabiele en beheerbare krag aan die afskileenheid. Die stelsel ondersteun 220V enkelfase of 380V driefase industriële krag.

Skeiding en versameling stelsel:

'n Onafhanklike uitlaatkanaal is ontwerp vir outomatiese skeiding en afvoer van die skil en pulp. Die pulp gly tipies ongeskonde uit deur die hoofuitlaat aan die voorkant, terwyl die skil van onafhanklike afsetpunte aan die kant of onder afgehaal word, die daaropvolgende prosesse aansienlik vereenvoudig.

Geïntegreerde begin, stop, en noodstopknoppies verseker operasionele veiligheid. Meer gevorderde modelle kan toegerus word met 'n eenvoudige spoedbeheertoestel om te verfyn vir verskille tussen groepe grondstowwe.

Ideaal vir piesangverwerking

Die weegbreeskillermasjien is nie net 'n toestel nie, maar ook 'n stel oplossings om piesangverwerkingsdoeltreffendheid te verbeter. Ons bied kliënte die hele prosesondersteuning vanaf toerustingkeuse, skema ontwerp, installasie, en ontfouting na na-verkope diens. Ons toerusting is na Suidoos-Asië uitgevoer, Suid-Amerika, die Midde-Ooste en Afrika, en ander lande en streke en is goed ontvang deur kliënte. Behalwe die groen piesangskilmasjien, ons beveel ook ander verwante toerusting vir jou aan:

- Groentesnymasjien: Dit kan geskilde piesangs eweredig sny of sny, wat geskik is vir daaropvolgende droog of braai.

- Outomatiese deurlopende braaier: Word gebruik om gesnyde piesangs eweredig te braai om bros piesangskywe en ander peuselkos te maak.

- Drum smaak masjien: Outomaties tuimel en meng, draai die geurmiddels eweredig op die oppervlak van piesangskywe toe om die smaak te verbeter.

Kontak ons gerus vir gedetailleerde inligting oor toerusting en pasgemaakte oplossings! Raadpleeg dadelik en laat jou piesangverwerkingsfabriek op die voorpunt van die bedryf loop!