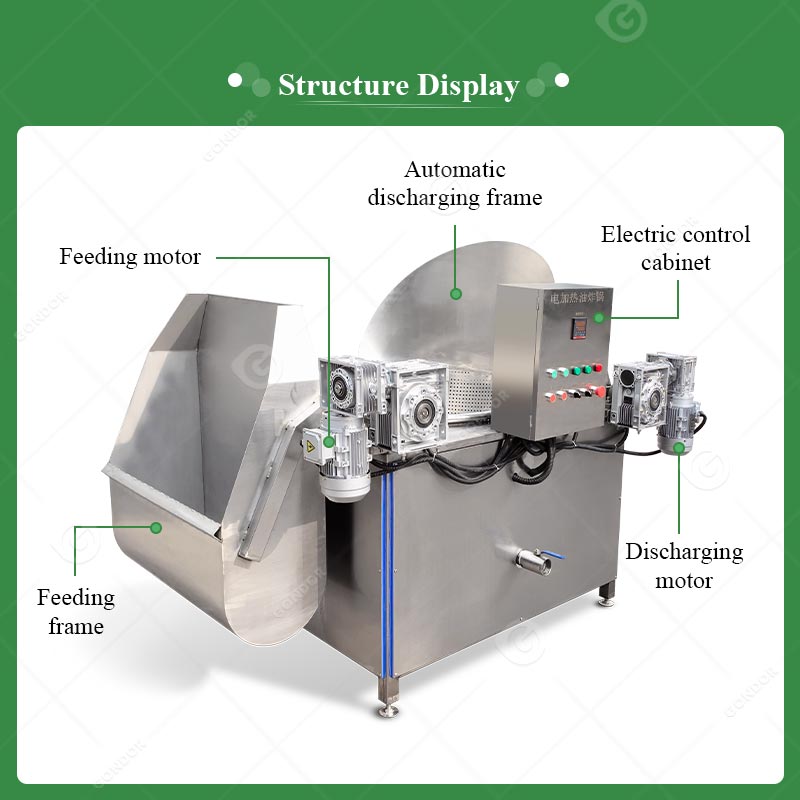

An industrial round deep fryer is an efficient frying equipment specially designed for food processing enterprises. The main equipment is made of food-grade SUS304 stainless steel, which has excellent corrosion resistance, veiligheid, en stabiliteit. Its innovative revolution and rotation synchronous stirring structure ensures that the ingredients are evenly heated and do not stick, thus effectively improving product quality and production efficiency.

This equipment is equipped with an intelligent temperature control system, which can realize accurate temperature control and automatic production, avoid burning of ingredients, and prolong the service life of grease. The industrial deep fryer is compact in structure and can be equipped with an automatic loading and unloading system, which can significantly save labor and cost. It is an ideal choice for food processing enterprises to improve their automation level.

| Model | Krag | Spanning | Frying Basket Diameter | Masjien grootte |

| GD-800 | 36KW | 380V 50hz | 800 | 1050*1000*1700 |

| GD-1000 | 48KW | 380V 50hz | 1000 | 1250*1200*1700 |

| GD-1200 | 60KW | 380V 50hz | 1200 | 1450*1400*1700 |

| GD-1500 | 78KW | 380V 50hz | 1500 | 1750*1700*1700 |

Application Market Range of the Industrial Deep Fryer

The industrial fryer machine is suitable for a variety of food processing industries and can meet the requirements of continuous frying production:

- French Fries /Potato Chips

- Nuts such as Peanuts

- Meat Products Meat Products

- Aquatic Products

- Spring Rolls/Snack Food

- Snack Processing Of Various Snack Foods

Outstanding Performance Advantages of Industrial Fryer Machine

Why Choose Our Round Deep Fryer?

- Redelike ontwerp, compact structure, and land saving.

- High degree of automation, arbeidskoste te verminder.

- No oil smoke, no food odor.

- The frying quality is stable, and the product grade is improved.

- It is suitable for a variety of foods and has strong expansibility.

- Safe and reliable, easy to maintain.

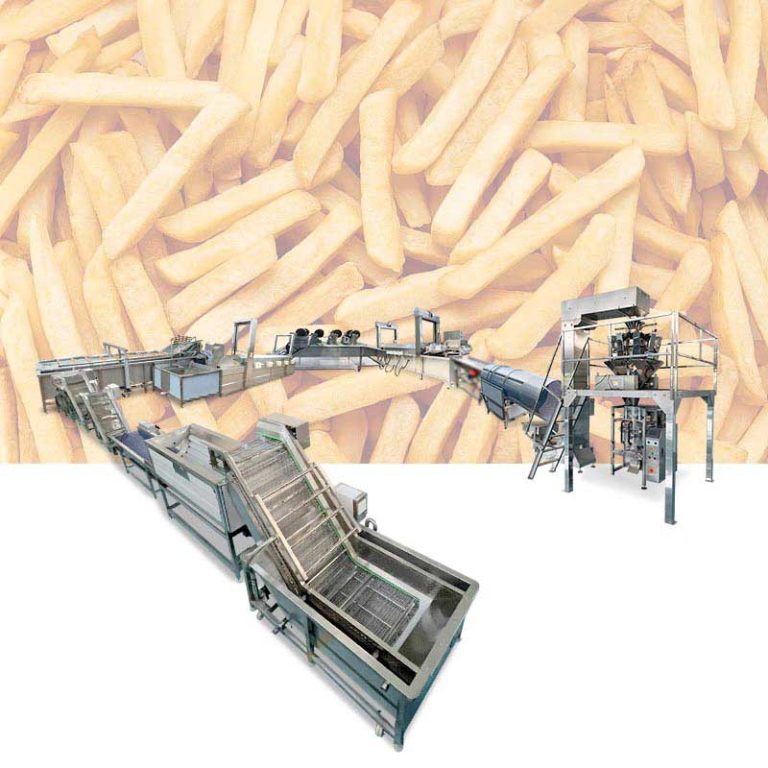

Recommended Supporting Equipment

To meet the needs of large-scale and automatic food processing, we also provide a variety of supporting equipment, which can form a complete production line with the frying machine:

-

- Bubble Washer Machine

- De-oiling Machine

- Potato Chip Seasoning Machine

- Verpakkingsmasjien