Gondor Industrial Soya Milk Processing Machine

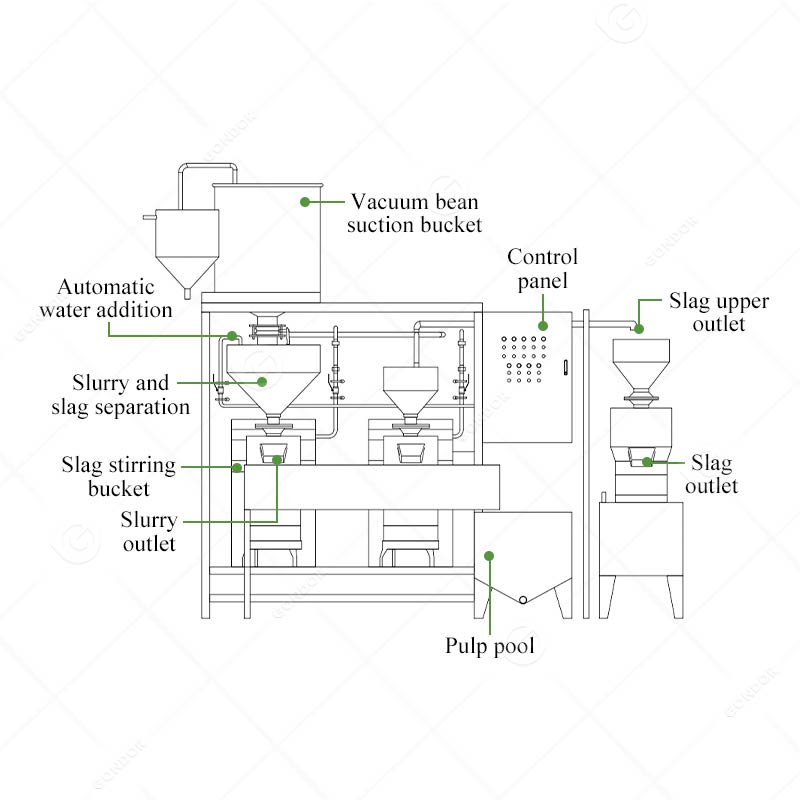

Industrial soya milk production machine is a highly efficient equipment designed for large-scale production of soymilk and soy products. It is widely used in food processing, spysenieringsbedryf, and soy product processing plants. The equipment adopts advanced grinding technology and an automatic filtering system to ensure fine slurry and pure taste. The vacuum bean suction system efficiently transports soybeans.

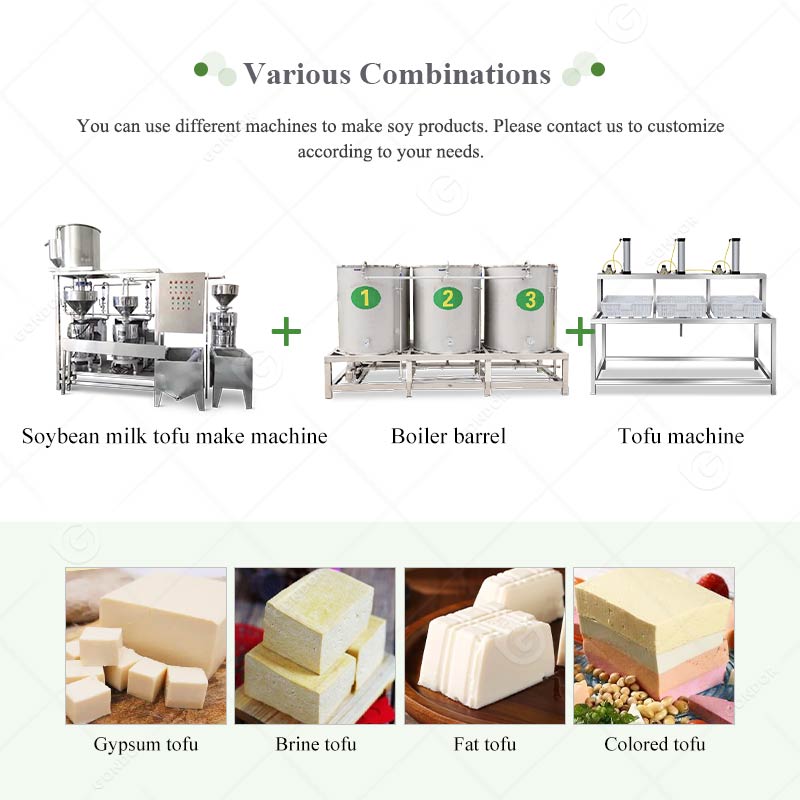

Na maal, it is heated and sterilized to ensure the safety and hygiene of soymilk production and meet the processing needs of various soy products such as tofu, tofu brain, and tofu pudding.

Industrial Soya Milk Production Machine Specification

|

Spanning |

Krag | Afmetings | Gewig | Uitset |

| 380V | 25kw | 2100*1350*2650mm | 350kg |

400-500kg/h |

|

380V |

28.5kw | 2400*1400*2600mm | 360kg | 400-500kg/h |

| 380V | 18kw | 2000*1600*2700mm | 340kg |

400kg/h |

Application Industries of Soya Milk Production Machine

Industrial soy milk machines are suitable for multiple industries due to their high efficiency and automation, meeting the production needs of soy milk and soy products of different scales.

Food processing companies use industrial soya milk production machines to mass produce soy milk as raw materials for soy products such as tofu, dried tofu, and bean skin, ensuring stable product quality and improving production efficiency.

Breakfast shops, fast food chains, central kitchens and other catering companies can use this equipment to quickly make fresh soy milk to meet the daily needs of a large number of consumers and improve operational efficiency.

Agricultural companies can use this equipment to deeply process soybeans, increase the added value of soybeans, create a soy product industry chain, and promote the modernization of agriculture.

With the growth of the plant protein market, many companies use this machine to produce soy milk as a healthy substitute for dairy products, supplying supermarkets, beverage shops and food processing plants.

Milk tea shops, soy milk specialty stores, ens. can use the soya milk production machine to achieve standardized production, ensuring the stable taste of each cup of soy milk and meeting market demand.

School canteens, large enterprises and institutions, hospitals and other group dining institutions can use industrial soybean milk machines to provide fresh and nutritious soybean milk drinks to ensure healthy diet.

Equipment Advantages of Soya Milk Extraction Machine

Industrial Soya Milk Making Machine FAQ

- V: What is the actual output of this machine? Does it support 24-hour continuous operation?

- 2. V: How does the produced soy milk taste? Is the pulp and residue separation thorough?

Daarby, the production line includes heating and sterilization processes, which not only ensure food safety but also remove the beany smell through high temperatures, preserving the natural rich flavor of the soy milk.

- 3. How many workers are needed to operate this machine? How automated is it?

- 4. What materials is the machine made of?

The main wear part is the grinding wheel, which is easy and inexpensive to replace. The company also provides 24/7 tegniese ondersteuning.

Verwante Toerusting Aanbeveling

The production process of the soya milk production machine involves multiple links, and its related equipment can work together to improve production efficiency and improve the processing process of soya milk and soy products.

- Vloeistofvulmasjien: Automatically fills soya milk into bottles, bags or cartons, suitable for retail or bulk sales.

- Melkpasteurisasiemasjien: Suitable for long-lasting soya milk, extending the storage time of soya milk through low-temperature sterilization.

- Refrigerated Storage Equipment: Used to store soya milk and soy products to keep the product fresh.