Gondor Pet Food Production Line

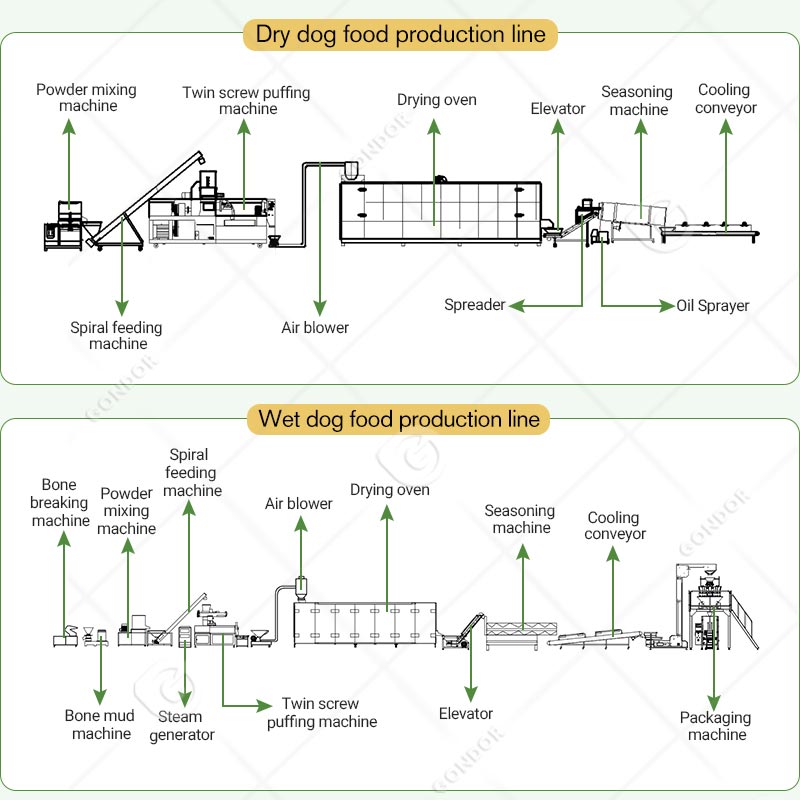

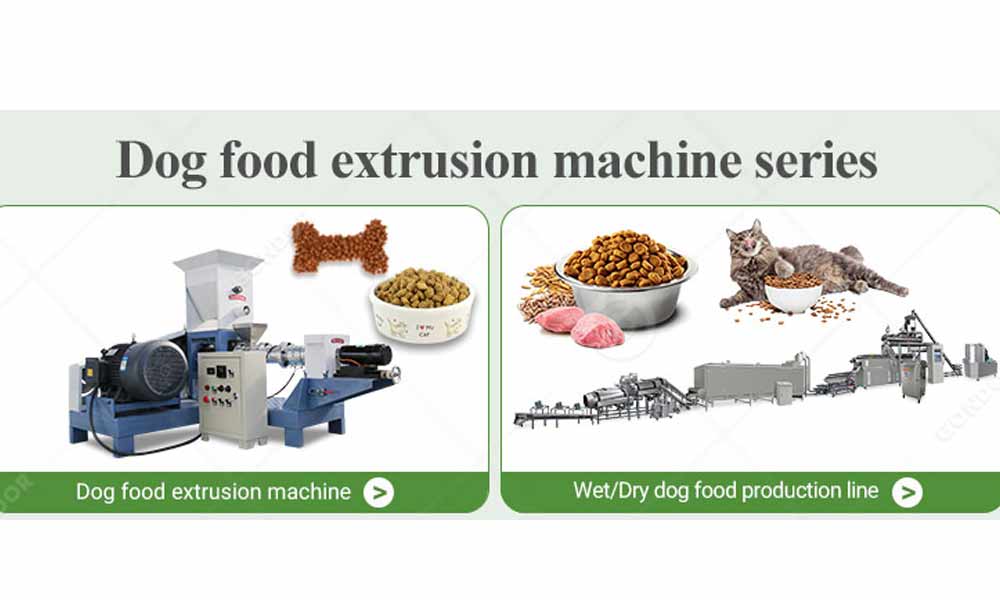

Die pet food processing line provided by Gondor integrates automation, high production capacity and precise temperature control, and is suitable for the production of pet food for dogs, cats, vis, birds, ens. High-quality products are ensured through processes such as formula customization, mold change molding, and strict quality inspection. The production process strictly controls the raw material ratio and combines puffing technology to produce crispy and nutritionally balanced pet food, which is very popular in the global market.

Pet Food Processing Line Specification

| Naam | Krag(kw) | Spanning(v) | Gewig(kg) | Grootte(mm) | Kapasiteit(kg/h) |

| Menger | 7.5 | 380v/50hz | 222 | 850x530x1040 | 40-50kg/time |

| Spiral feeder | 1.5 | 100 | 850x750x2450 | With the host | |

| Steam generator | 72 | 200 | 900x800x1200 | 100 | |

| Twin screw extruder | 35 | 1473 | 2500x1000x1800 | 220-300kg /h | |

| Air conveyor | 0.75 | 41 | 2000x600x1900 | With the host | |

| Dryer | 40 | 2000 | 5300x1200x1900 | With the host | |

| Geur masjien | 3.5 | 234 | 3100x900x1800 | With the host |

Pet Food Processing Line Is Suitable for Various Industries

This pet food processing line is widely used in many industries such as pet food manufacturers, animal feed processing plants, pet food brands, trading companies, OEM/ODM foundry companies, ens., to meet the different needs of the global market for dry pet food and wet pet food. Whether it is a pet food factory with large-scale production or a brand seeking high-quality customized products, this production line can provide efficient and stable solutions. Terselfdertyd, the equipment supports a variety of formula customization to meet the nutritional needs of different pets, helping companies improve their market competitiveness.

The Core Advantages of Gondor Pet Food Line

Verwante Toerusting Aanbeveling

To further optimize pet food production, we also provide the following equipment to improve production efficiency and product quality:

- Bone Crusher Machine: Crushes bones into fine particles for subsequent grinding.

- Bone Mud Machine: Grinds and crushes bones to form fine bone mud to improve calcium absorption.

- Inclined Screw Conveyor: Evenly lifts materials without leakage or pollution.

Our pet food processing line has been exported to many countries around the world, helping pet food companies expand their markets and improve their competitiveness. If you are looking for efficient and reliable pet food production equipment, please contact us immediately and we will provide you with customized solutions!