Gondor Semi-auto French Fries Production Line

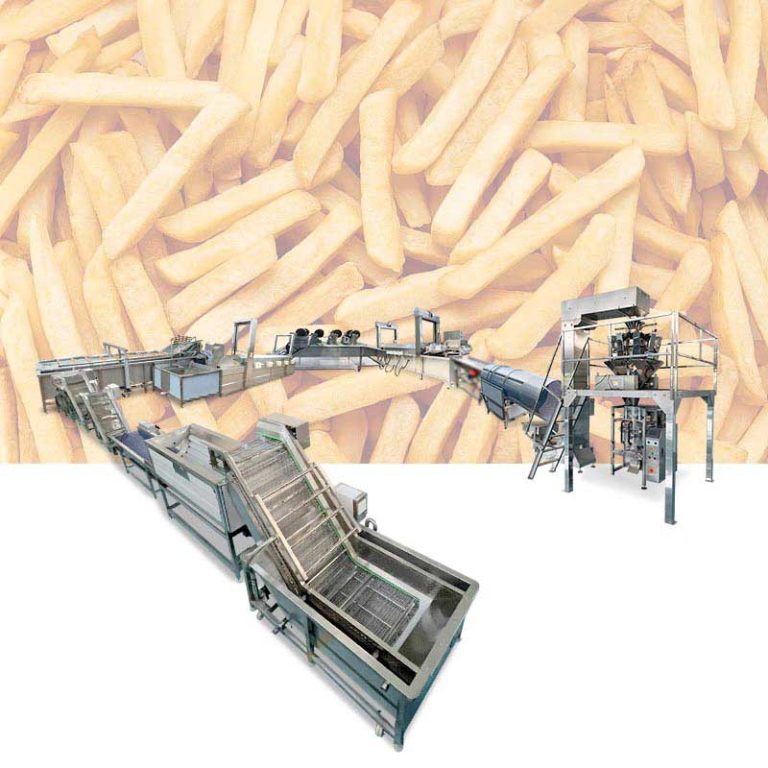

Ons semi-automatic french fries production line ensures efficient and standardized production, stabiele kwaliteit, and energy-saving operation. Vlekvrye staal, duursaam, waterproof, in line with food hygiene standards. The equipment covers the whole process from raw potatoes to packaging, which realizes automatic production and helps enterprises maintain their competitiveness.

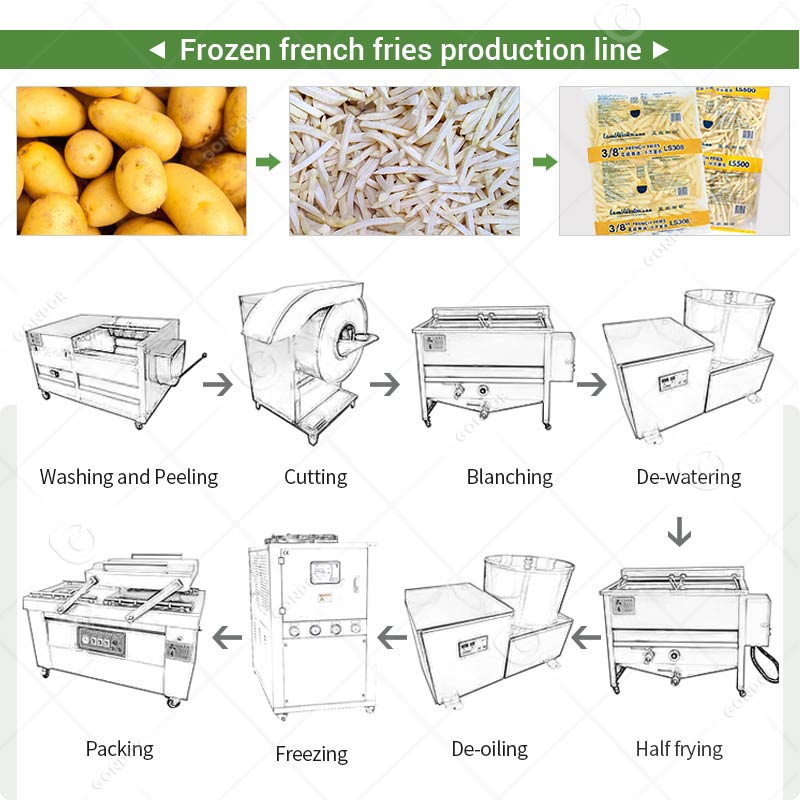

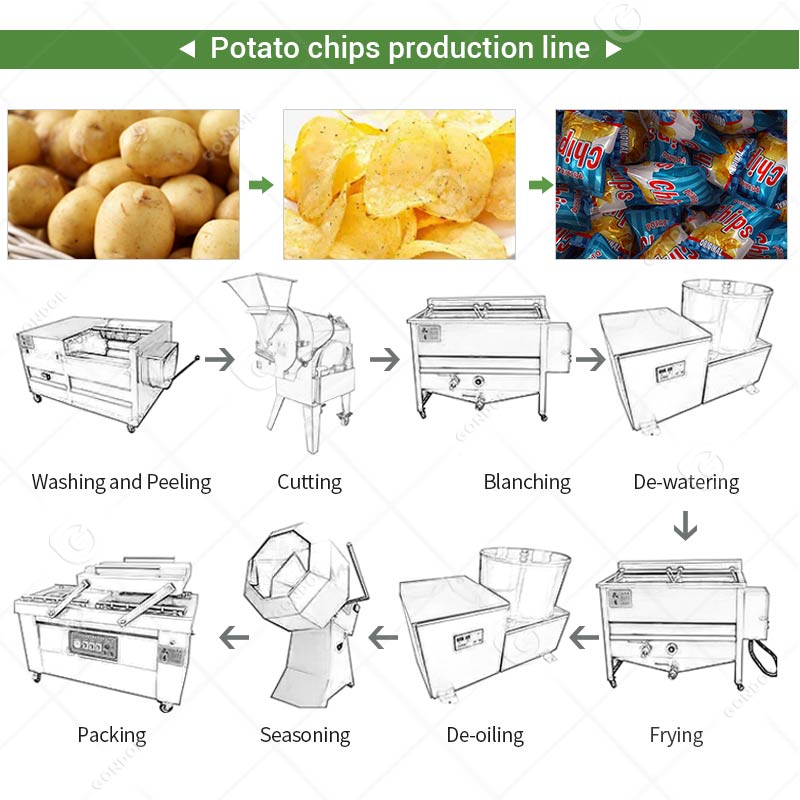

Semi-automatic French fries production line components

A semi-automatic French fries processing line refers to a fries processing system where, while key individual machines (washing, afskilfering, sny, braai, ens.) geoutomatiseer is, some processes (such as feeding, transfer, quick-freezing loading/unloading, verpakking, ens.) still require manual assistance.

Common production line machines include the following:

- Funksie: This machine thoroughly washes the raw potatoes, removing the skin, dirt, impurities, and outer layer, improving hygiene standards for subsequent processing and preparing them for cutting and frying.

- Kenmerke: Utilizes food-grade stainless steel, a design combining aerated water flow and roller brushes for thorough cleaning and high peeling rate; compact structure, maklik om skoon te maak, reducing manual pre-processing time.

- Funksie: Cuts the washed potatoes into uniform strips or slices, ensuring even heating of the fries or chips during subsequent processing, resulting in a consistent texture in the finished product.

- Kenmerke: Replaceable blades, adjustable thickness; smooth cut without damaging the texture, adaptable to different product specifications (bv., thin potato chips or long French fries).

- Funksie: Quickly heats cut potato fries/slices with hot water or steam to remove excess starch, inhibit enzyme activity, improve the color and texture of the finished product, and reduce breakage during frying.

- Kenmerke: Adjustable temperature and time help maintain the natural color of the product and enhance the crispy texture after frying.

- Funksie: Removes excess moisture from the surface of blanched potato fries/slices using centrifugation or vibration, reducing moisture for the frying stage and improving frying efficiency.

- Kenmerke: Highly efficient dehydration, eenvoudige operasie, reduces oil and water splattering during frying, improving safety and production stability.

- Funksie: Deep-frys dehydrated potato fries/chips in hot oil until cooked through and crispy on the outside. This is the core process for achieving the final texture and flavor.

- Kenmerke: Controllable oil temperature, even oil circulation for rapid and uniform browning; electric or gas heating options available.

- Funksie: Places deep-fried potato chips/fries into the de-oiling machine, where centrifugation or vibration removes excess surface oil, reducing the oil content of the finished product and improving taste and health.

- Kenmerke: High de-oiling efficiency, maklike operasie, helps extend product shelf life and enhances the consumer experience.

- Funksie: Evenly sprinkles seasonings onto the de-oiled product, imparting different flavors and making the finished product more appealing to the market.

- Kenmerke: Even seasoning, adjustable speed and types of seasonings to meet various customized flavor requirements.

- Funksie: Automatically weighs and packages seasoned potato chips/fries for easy storage, sales, and transportation.

- Kenmerke: Enables automatic weighing, gas-filled or vacuum packaging, and sealing, significantly improving packaging speed and hygiene standards.

Semi Automatic French Fries Production Line Specification

| Device name | Krag(Kw) | Afmetings(mm) |

| Skoonmaak- en afskilmasjien | 1.5 | 1750x900x900 |

| Potato cutting machine | 0.75 | 850x850x1000 |

| Blanching machine | 24 | 1400X600X1050 |

| Potato dehydrating machine | 0.75 | 850x500x600 |

| Chips frying machine | 24 | 1400X600X1050 |

| Chips de-oiling machine | 0.75 | 850X500X600 |

| Geur masjien | 1.1 | 1400X900X1700 |

| Packing machine | 1.5 | 800X500x100 |

Industries Suitable for Semi-Automatic French Fries Production Line

The production line is suitable for all kinds of food processing industries, and both small entrepreneurs and large food manufacturers can benefit from it.

Efficient cutting, braai, and seasoning to ensure crisp taste and uniform appearance of potato chips.

Precise cutting, water control, and quick freezing can improve the quality of frozen French fries, which is suitable for the global supply chain.

Provide diversified flavor modulation and automatic packaging to help snack enterprises produce on a large scale.

Efficiently produce standardized French fries, meet the rapid supply needs of fast food chain stores, and ensure a stable taste.

Automate packaging and quality control to ensure that products meet market standards and are convenient for supermarket sales.

Whether you want to expand the existing market or establish a brand-new french fries business, this production line can provide stable and efficient solutions.

Considerable Benefit Advantages of Frozen French Friends Production Line

Meer verwante toerusting-aanbevelings

In addition to the semi-automatic french fries production line, we also provide other food processing equipment, soos:

- Ten volle outomatiese aartappelskyfies-produksielyn – Suitable for large-scale food production enterprises.

Welcome to contact us to get customized solutions and quotation information to make your food processing business by going up one flight of stairs!