Food Packaging Water Bath Pasteurizer Machine

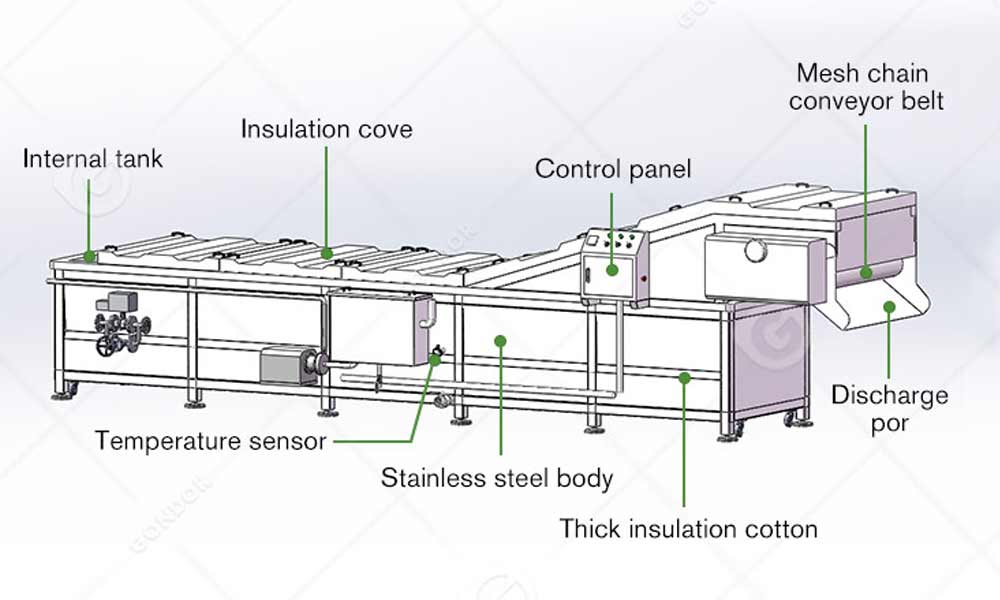

A water bath pasteurizer is an advanced automation system. It is an ideal choice for heat-sensitive food processing to realize continuous operation through precise temperature control. It is made of durable SUS304 stainless steel, equipped with a PLC and a touch screen control device, which can easily adjust sterilization parameters while ensuring stable operation. Daarby, the energy-saving heat recovery and automatic filtration system of the bath sterilizer reduces energy consumption, ensures uniform heating, and prolongs the shelf life.

Water-Bath Pasteurizer Specification

| Water bath pasteurizer | |

| Verhitting metode | steam heating |

| Sterilization time | 3-60 minute (adjustable) |

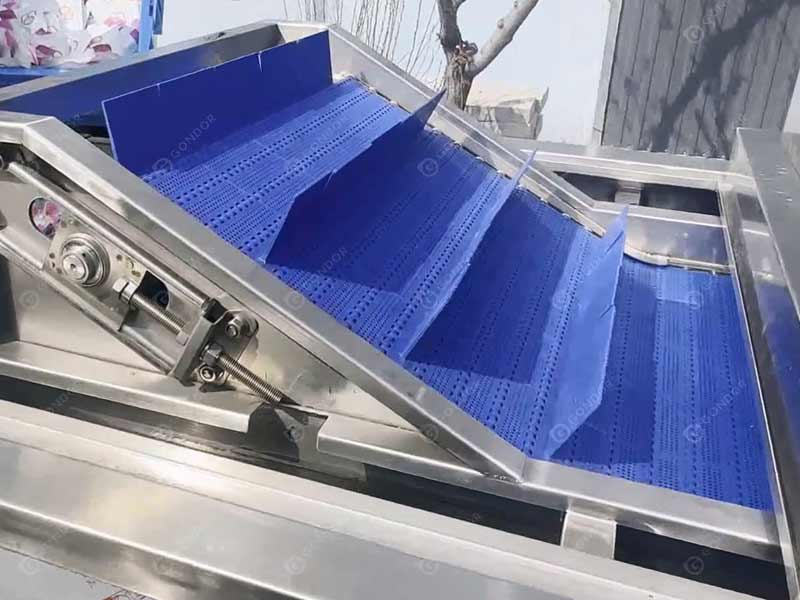

| Mesh belt | double layer |

| Processing | Verhitting + Pasteurizing +Cooling |

| Toepassing | Bottle/Pouch Package Pasteurizer |

| Suitable for | Drink/Food Pasteurization Factory |

| Volume | Verstelbaar |

| Materiaal | 304 Vlekvrye staal,Pasgemaak |

| Sertifisering | ISO 9001, ISO 14001, ISO 45001, CE, BSCI, ETL |

Industry Served by Water Bath Pasteurizer

Water bath pasteurizer is widely used in the global food and beverage processing industry. Whether it is a small manufacturer or a large industrialized factory, the equipment can meet diversified needs and support various packaging forms such as bagging, bottling, canning, and palletizing.

Key Application Areas

Melk, jogurt, kaas, and other dairy products are safer after pasteurization, while retaining fresh flavor.

Fruit juice, vegetable protein drinks, and herbal drinks can achieve uniform sterilization while maintaining natural taste.

All kinds of sauces, soups, and prepared vegetables can keep their flavor and texture after low-temperature sterilization.

Packaged clean vegetables, pickled vegetables, preserved fruits, and other products can be safely sterilized and retain nutrition.

Remarkable Characteristics of Steam Pasteurization Equipment

Related Food Processing Solutions

In addition to the tunnel pasteurizer, we also provide a full range of complementary equipment for complete food processing lines, insluitend:

- Lug droogmasjien – To stabilize product temperature after sterilization.

- Double Chamber Vacuum Sealer-Extend the shelf life of products.

- Retort Sterilizer-Suitable for product treatment requiring higher temperature.