Gondor Cocoa Bean Crusher Introduction

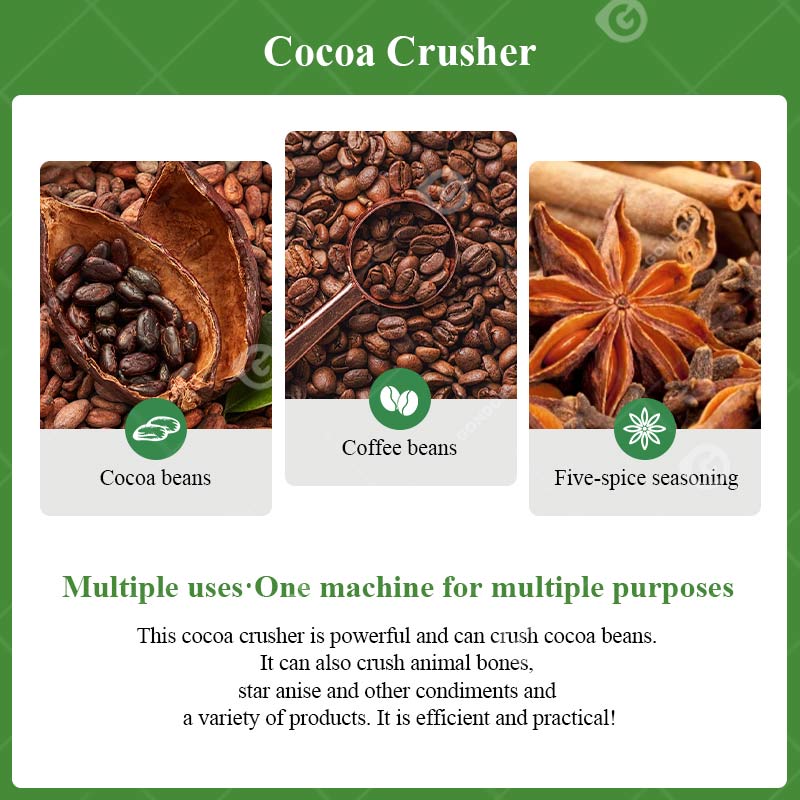

দ cocoa bean crusher is a powerful and multi-purpose grinding solution designed to efficiently process cocoa beans, কফি বিন, and a wide range of dry spices. As an industrial cocoa crusher, this cocoa grinding mill is suitable for both small-scale operations and large food processing plants. It can also handle hard materials such as animal bones, star anise, and other condiments, demonstrating strong adaptability across different industries. As a professional cocoa crusher machine manufacturer, we provide reliable solutions for diverse crushing requirements.

This cocoa grinder machine delivers smooth and consistent crushing performance, converting raw cocoa beans into uniform granules for chocolate production, coffee processing, and further downstream applications. Built with a robust structure and durable components, the machine is designed for long-term, স্থিতিশীল অপারেশন, making it a dependable cocoa mill grinder for industrial use.

Gondor Cocoa Bean Crusher Models

Our cocoa bean crusher designed with advanced technology, capable of flexibly adjusting the feed size, grinding fineness, and output according to different production requirements. Whether for small batch production or large-scale processing, this industrial cocoa grinder can quickly and evenly process cocoa beans into the desired particle size, ensuring product quality and processing efficiency.

| মডেল | 180 | 300 | 400 | 500 | 600 | 800 | 1000 |

| Feed Size(mm) | 180*190 | 310*210 | 420*230 | 520*250 | 620*320 | 820*650 | 1100*800 |

| Material Handling Dimensions(mm) | 4-30 | 4-50 | |||||

| Yield(kg/h) | 20-60 | 80-200 | 150-400 | 200-600 | 300-900 | 800-2500 | 1000-4000 |

| Power(kw) | 3 | 5.5 | 7.5 | 11 | 15 | 30 | 45 |

| Voltage(v) | 380 | ||||||

| Overall Size(mm) | 720*450*900 | 1250*730*1150 | 1350*860*1200 | 1500*980*1450 | 1600*1100*1550 | 1750*1350*1550 | 1900*1500*1700 |

| Weight(mm) | 160 | 340 | 420 | 600 | 800 | 2000 | 3800 |

| Screen Aperture(mm) | 5-50 | 5-80 | 5-100 | ||||

How Do I Clean and Maintain the Grinder for Oily Cocoa Materials?

- Stop and disconnect the power before cleaning to ensure safe operation.

- Disassemble the contact parts such as the feed hopper, ব্লেড, and screen, and remove cocoa residues promptly to prevent oil buildup.

- Clean with warm water or food-grade detergent, then dry all parts thoroughly to avoid residue sticking or corrosion.

- Avoid water on the motor and electrical components; wipe these areas with a dry or slightly damp cloth only.

- Perform regular inspections of blades and screens, and replace worn parts to maintain crushing efficiency.

- Clean the machine immediately after use, especially when processing oily cocoa, to prevent hardening and clogging.

What Are the Moisture Requirements for Cocoa Beans Before Crushing?

Cocoa beans have specific moisture requirements before crushing, and proper moisture control helps improve crushing performance while reducing clumping and oil release:

- Moisture Content Requirement: It is generally recommended to keep the moisture content of cocoa beans at around 6%–8%. Excessive moisture may cause sticking and screen clogging, while overly dry beans can increase dust.

- Roasted Cocoa Beans: Properly roasted cocoa beans become more brittle, making them easier to crush with more uniform particle size, and helping reduce heat buildup and oil release during processing.

- Processing Tips: Ensure cocoa beans are fully dried and cooled before crushing, and avoid feeding materials at high temperatures to maintain stable operation and consistent output.

Gondor Cocoa Bean Crusher Application Materials

Designed for high-strength crushing of cocoa beans with uniform output, suitable for continuous industrial production.

Capable of stable crushing of coffee beans, meeting large-scale pre-crushing and processing requirements.

This cocoa grinder can chop finished chocolate into small pieces to make chocolate chips.

Handles hard materials such as beef bones and pork bones, ideal for meat processing and pet food industries.

Suitable for crushing high-hardness spices such as star anise and cinnamon with reliable performance.

Processes nuts, মটরশুটি, and other hard agricultural materials for various industrial applications.

Gondor Cocoa Bean Crusher Application Industries

What Screen Mesh Size Is Suitable for a Cocoa Bean Crusher?

The choice of screen mesh mainly depends on the target particle size and downstream processing requirements:

- 5-8 মিমি: Produces finer particles, suitable for cocoa nib processing, but with relatively lower capacity.

- 10–20 mm: The most common coarse crushing range, offering uniform granules with less heat generation, ideal for cocoa pre-processing.

- 20–30 mm: Produces larger particles with higher throughput, suitable for pre-crushing applications.

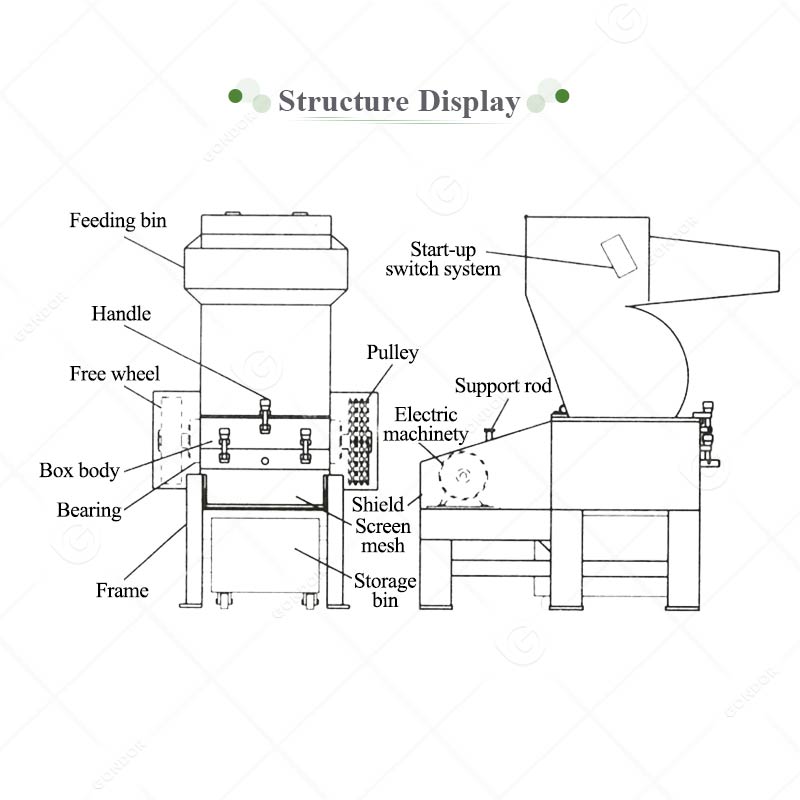

Gondor Cocoa Bean Crusher Features

- উচ্চ দক্ষতা & কম শক্তি খরচ: Delivers high crushing efficiency with low power consumption, ideal for continuous cocoa bean pre-processing.

- নিরাপদ & সহজ অপারেশন: Simple operation with protective design reduces splashing and operational risks.

- Automation Ready: Can be integrated with a belt conveyor for automatic feeding and discharging, শ্রম তীব্রতা হ্রাস.

- ইউনিফর্ম কণা আকার: Cutting-angle blade and guiding structure ensure smooth crushing and consistent output.

- টেকসই & Wear-Resistant: Alloy steel blades with special treatment provide excellent wear resistance and long service life.

- Customizable Output Control: Motor power and screen mesh can be customized to meet different capacity and particle size requirements.